Analysis of the titanium-bearing pellets prepared by a waste titanium-based catalyst and vanadium titanomagnetite

-

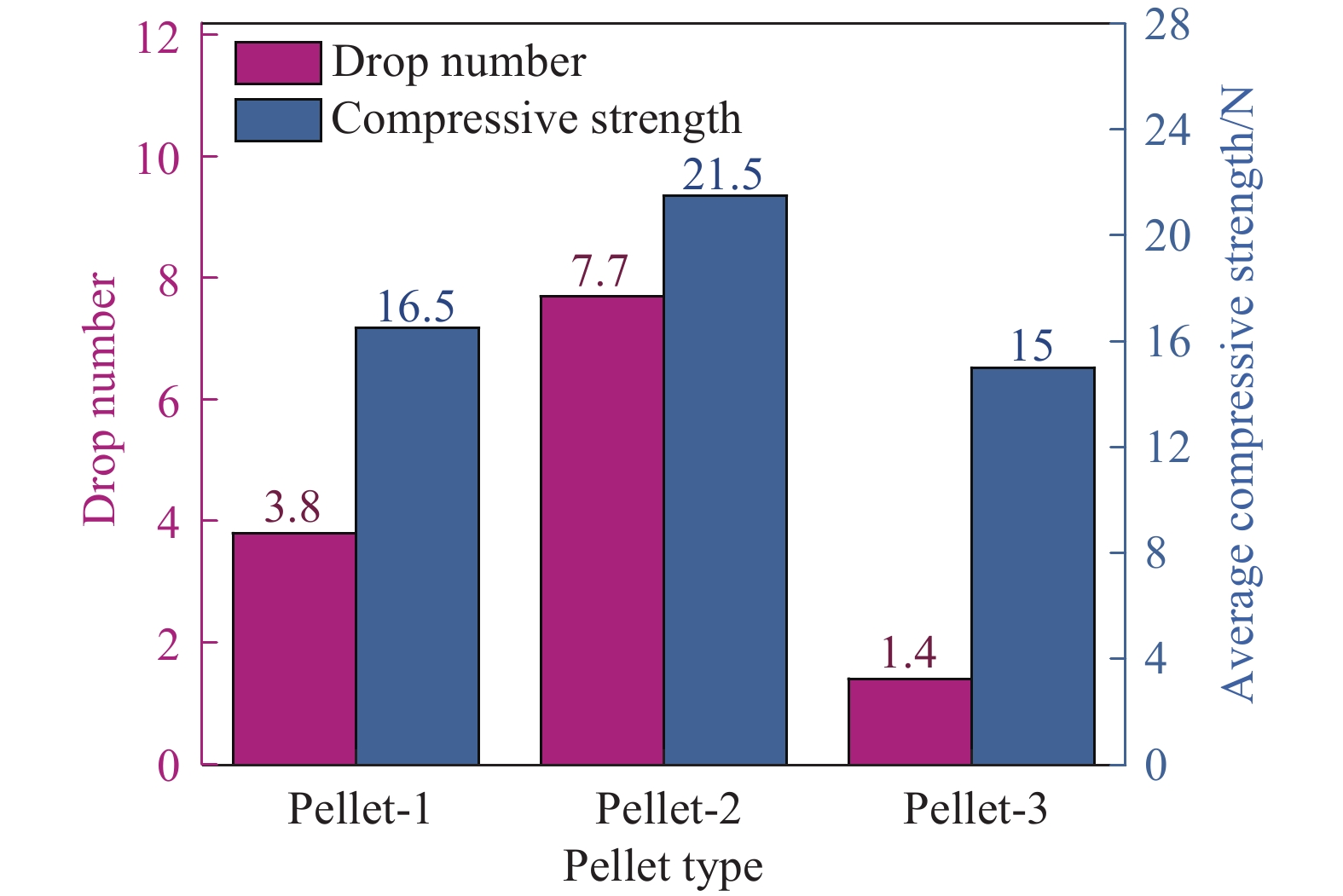

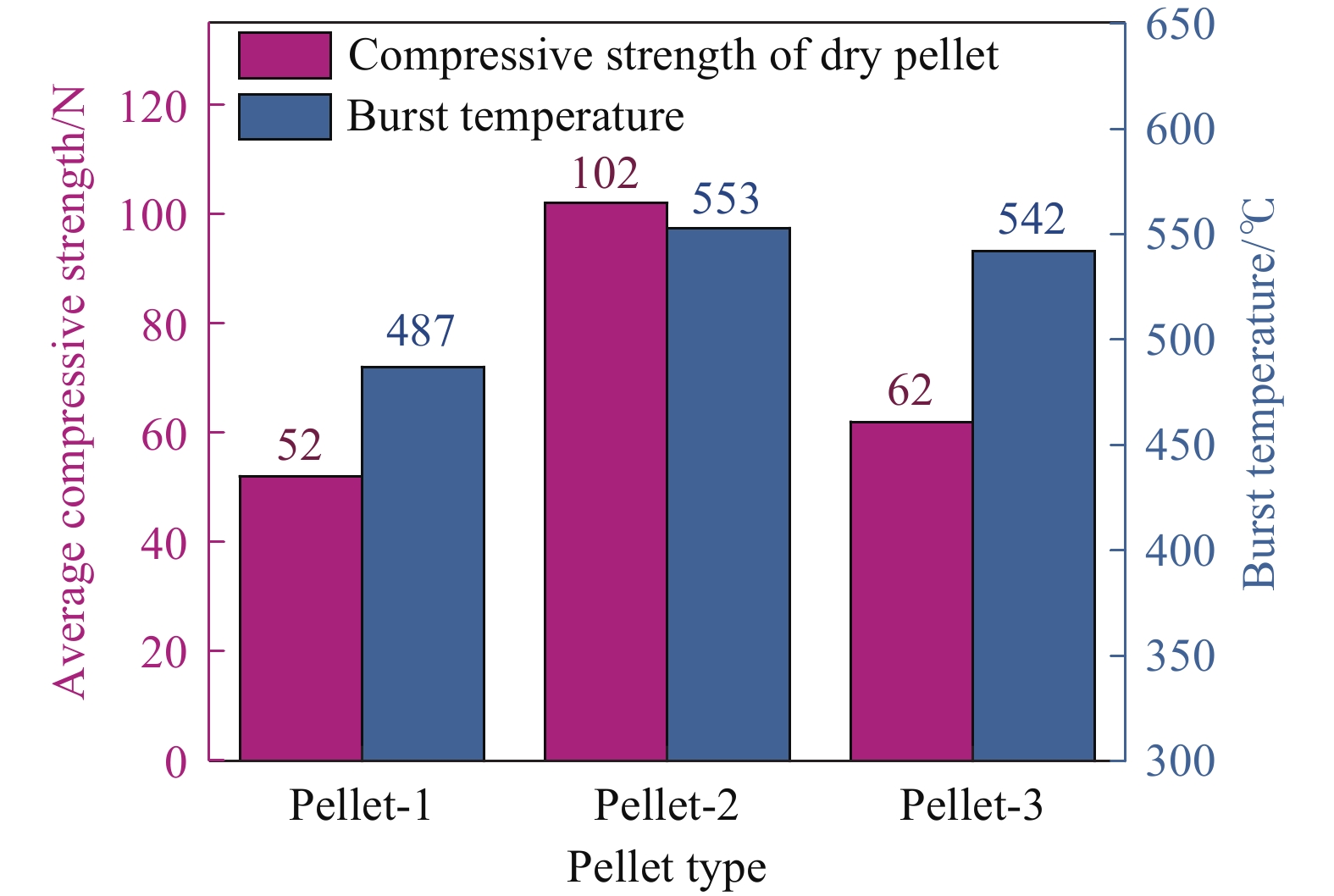

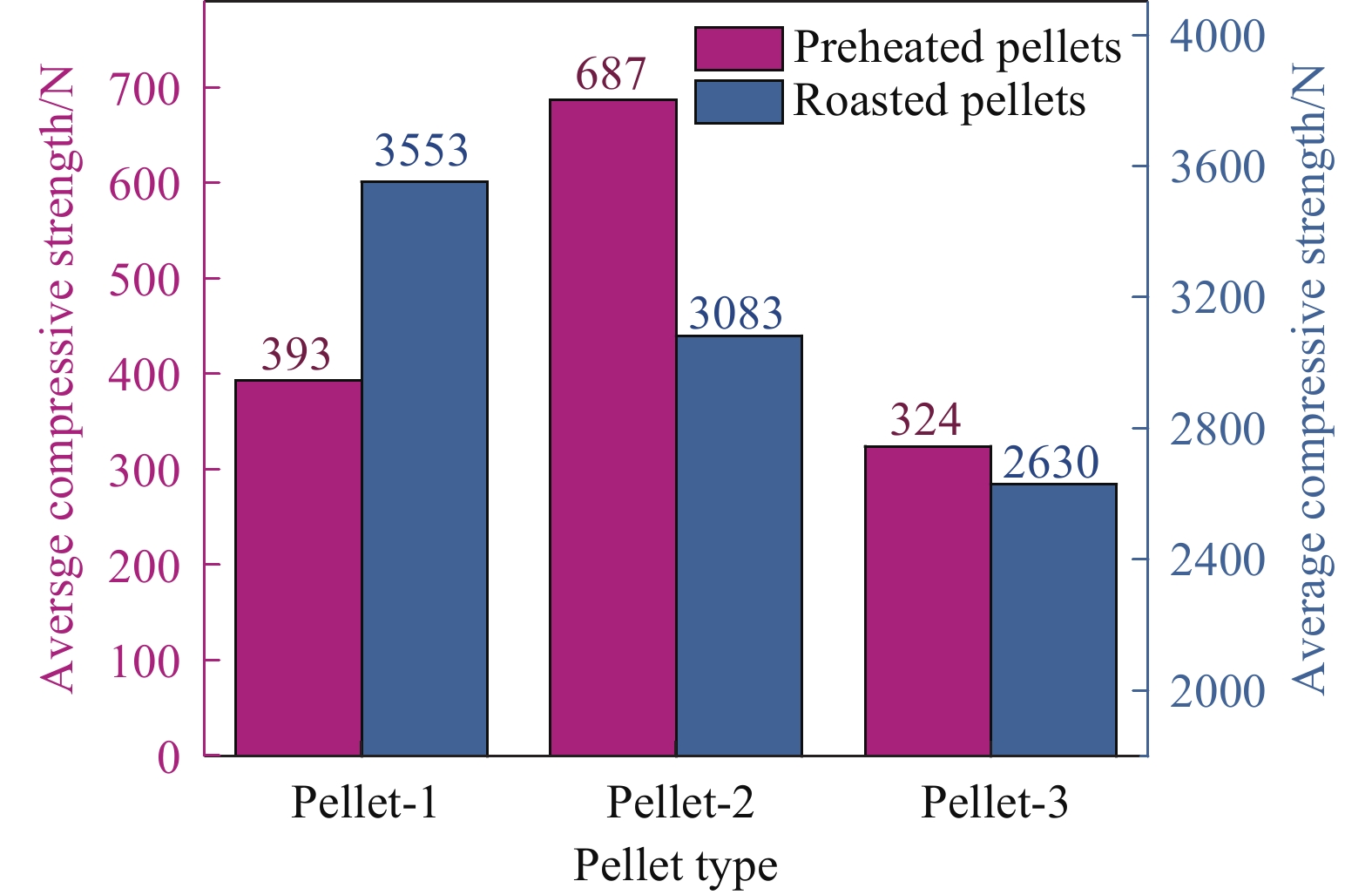

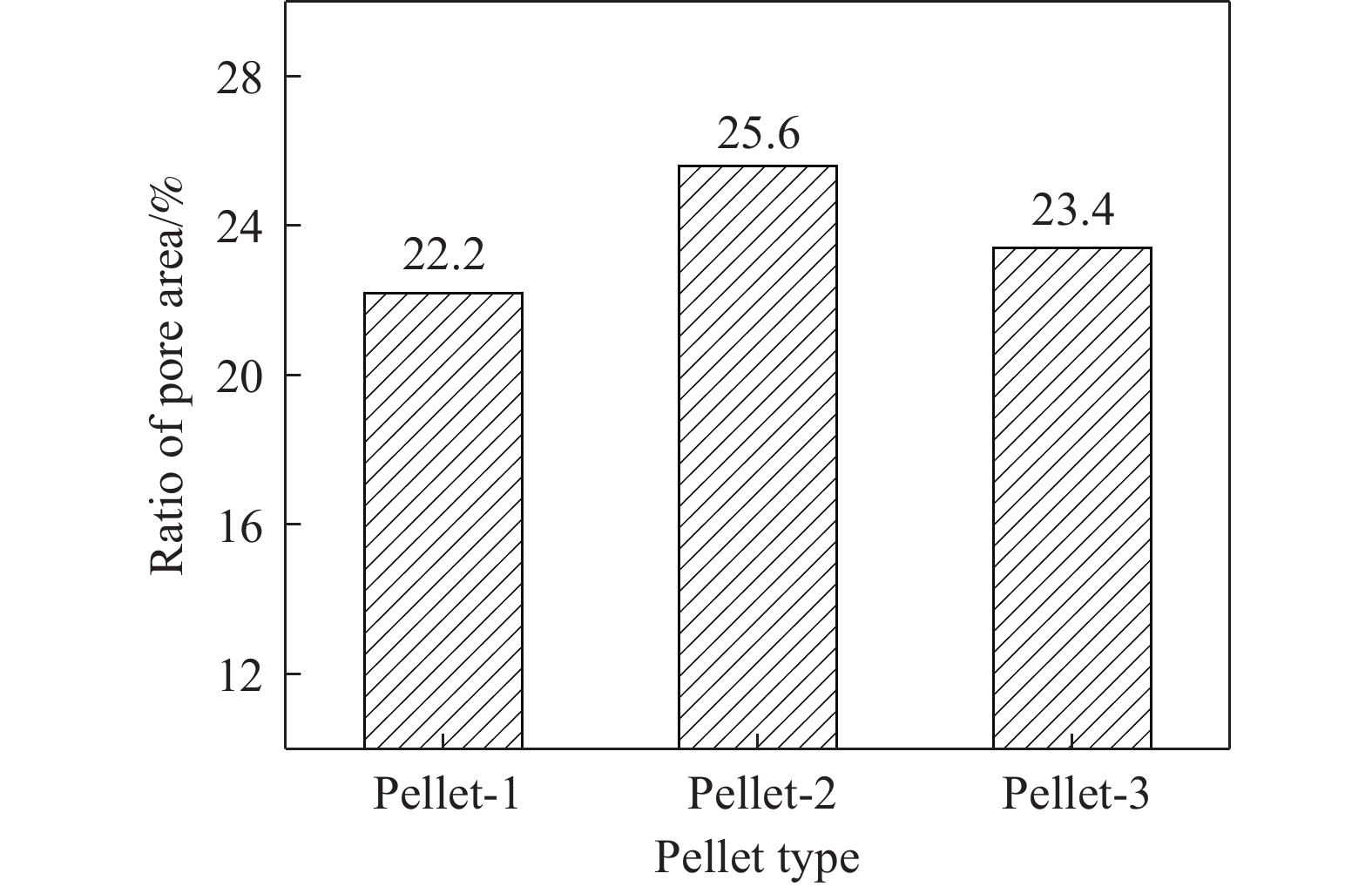

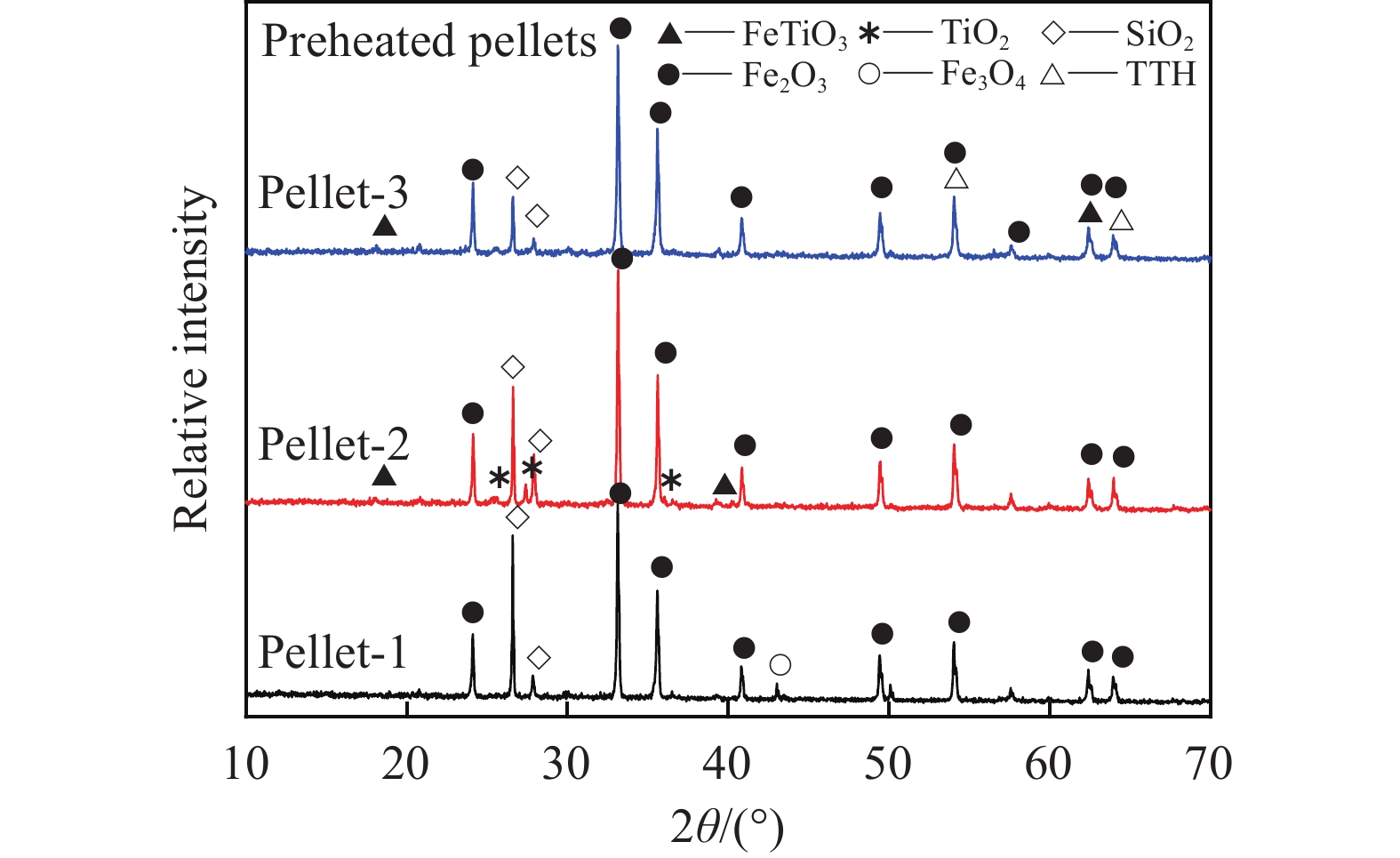

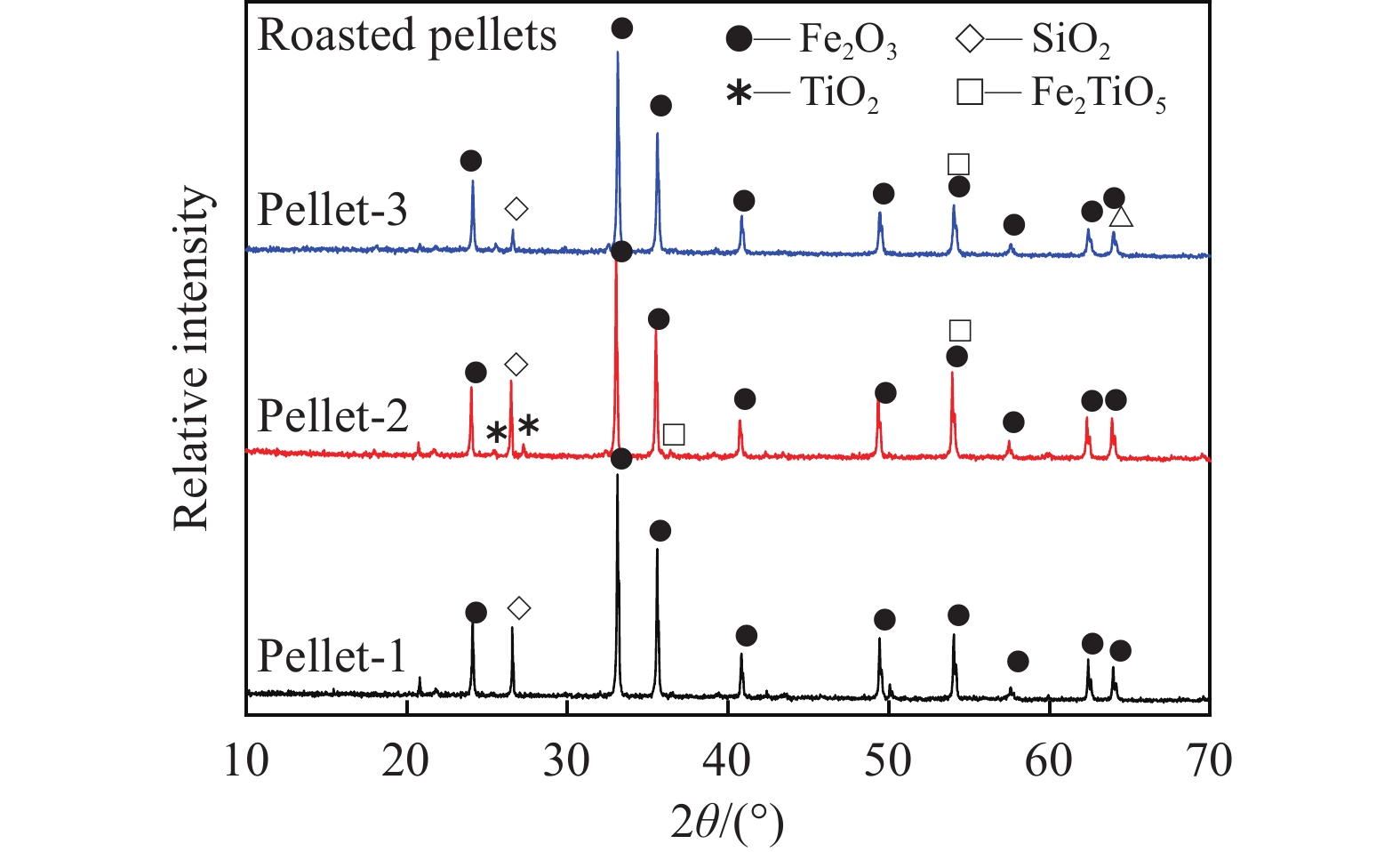

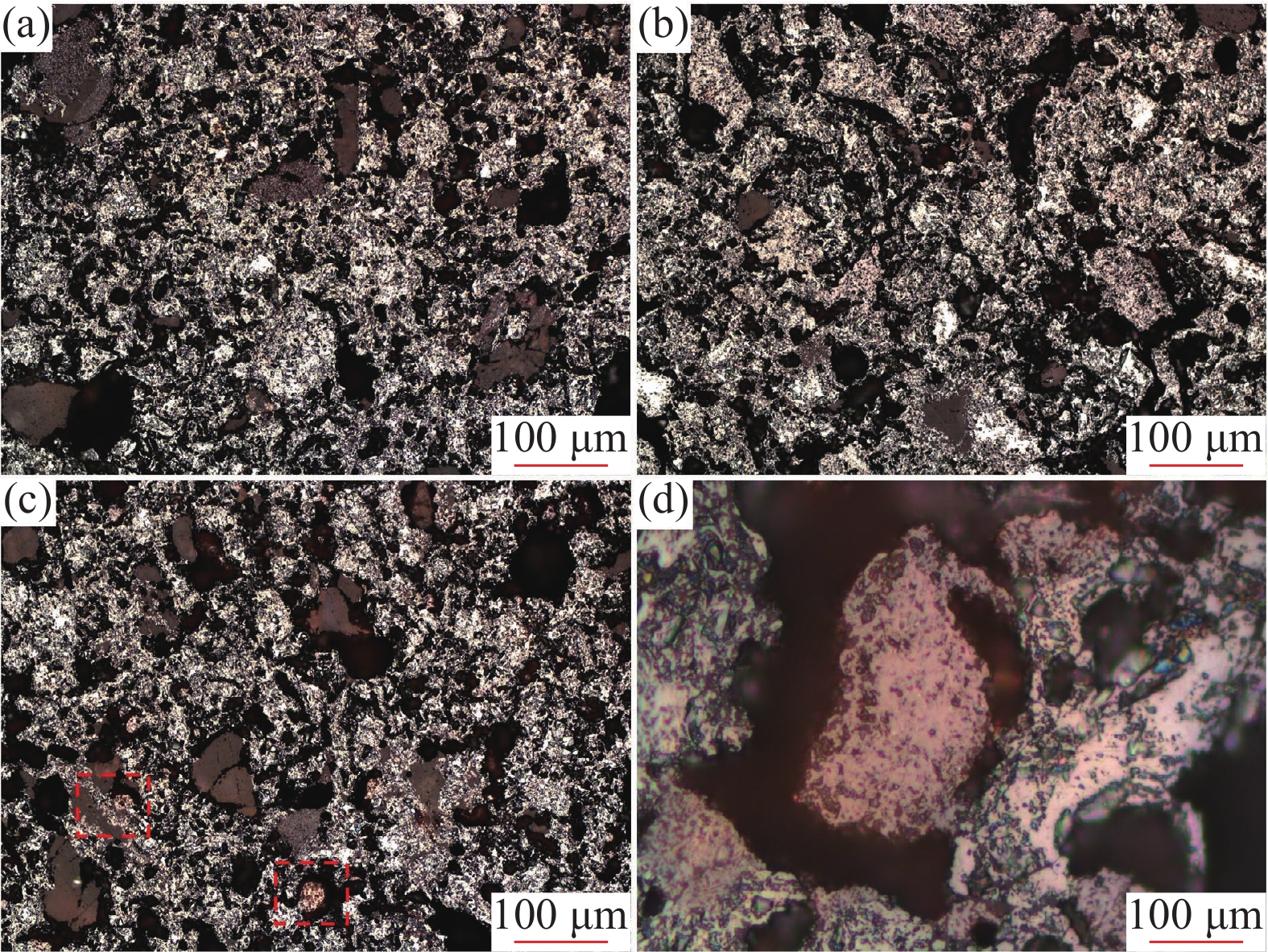

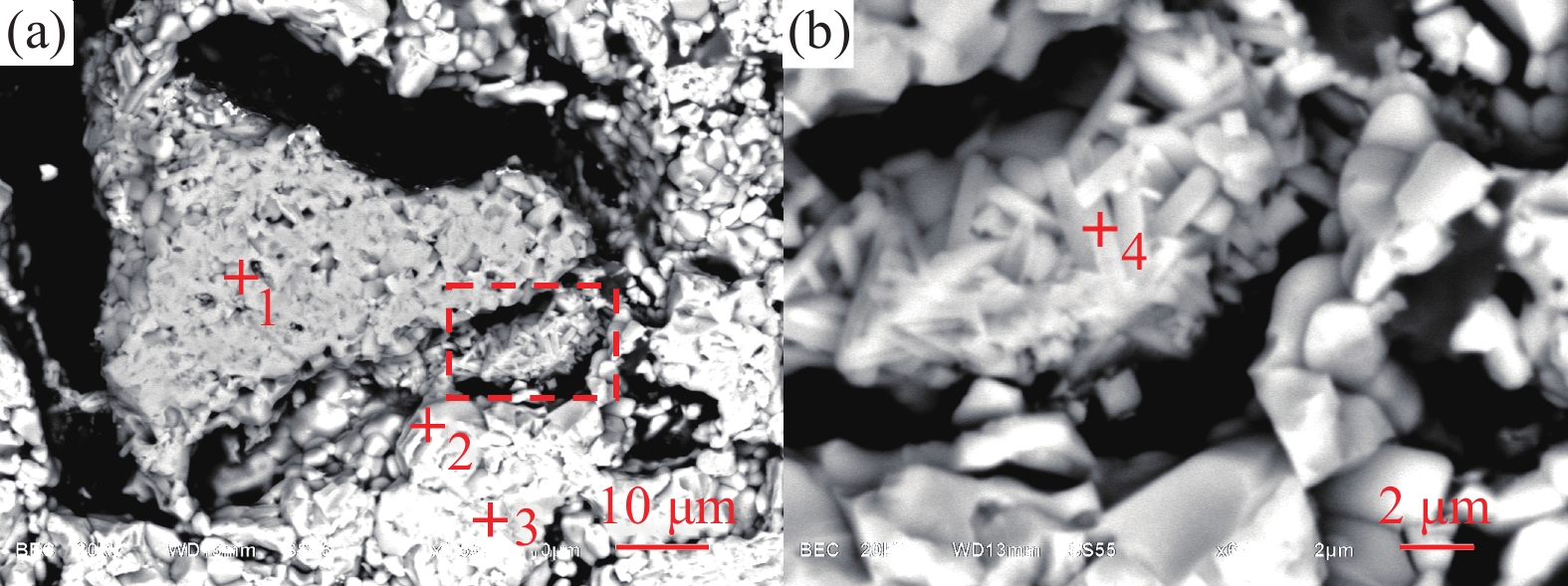

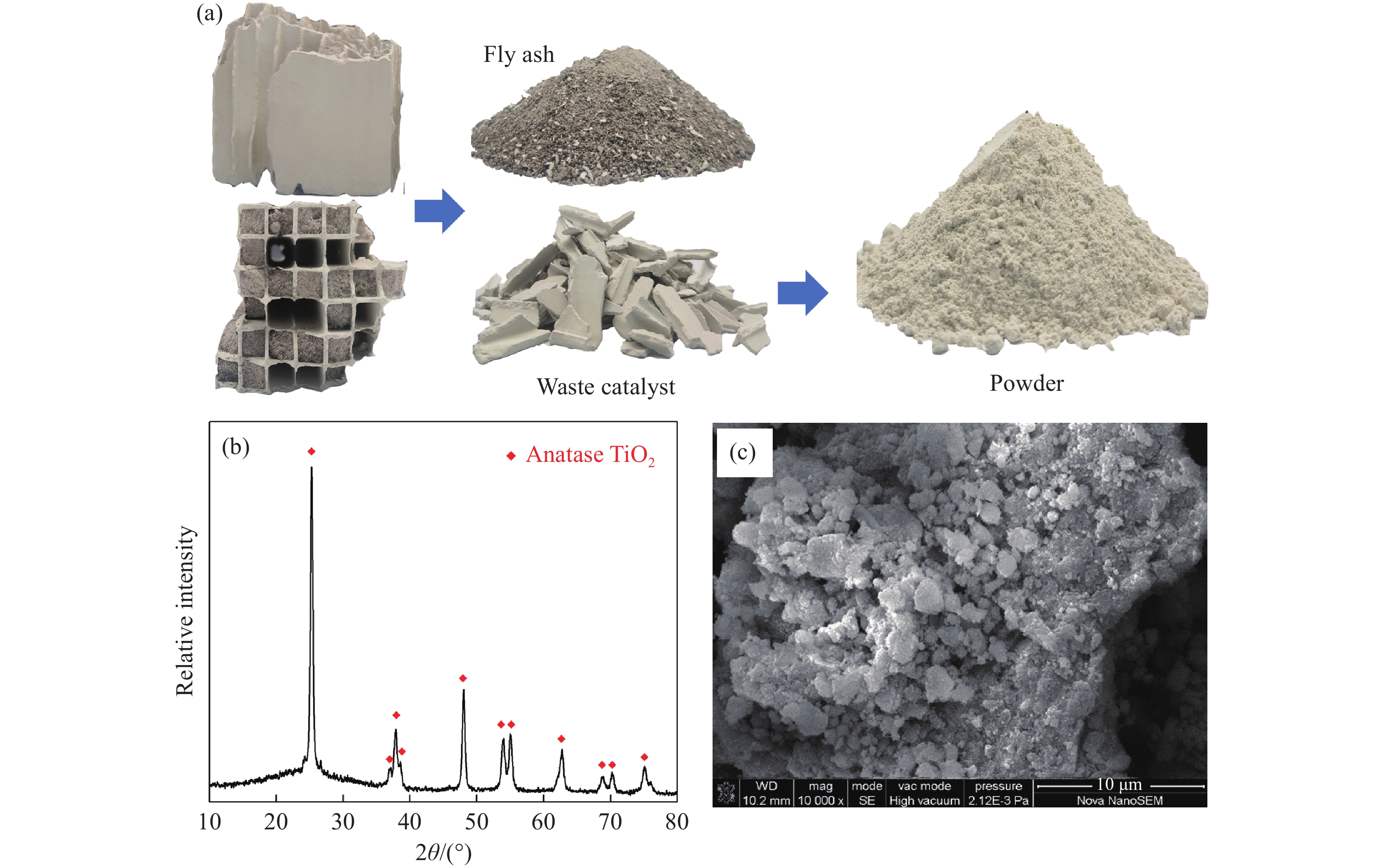

摘要: 鋼鐵企業煙氣脫硝廢催化劑(危廢)產生量逐年增加,加強對此類廢催化劑的有效處置與利用已成為行業急需解決的關鍵共性難題。本研究首次提出了將廢催化劑添加到球團原料中制備含鈦球團利用的新路徑。將含廢催化劑球團和市場普通含鈦球團的制備過程及冶金性能進行對比研究。結果表明:球團原料中添加質量分數5.0%的廢催化劑可以顯著提高生球綜合性能指標,且明顯優于以釩鈦磁鐵礦制備的普通含鈦球團。球團焙燒后,含廢催化劑球團平均抗壓強度為3083 N,高于普通含鈦球團的2630 N含廢催化劑球團固結機理表明,廢催化劑中TiO2與鐵氧化物反應形成Fe2TiO5相粘結,部分未反應TiO2會降低球團抗壓強度。兩種含鈦球團冶金性能與普通氧化球團基本相同,說明含廢催化劑球團可以用于高爐護爐冶煉使用。本研究有望為鋼鐵企業煙氣脫硝產生的廢催化劑在企業內部資源化利用提供新思路。Abstract: NH3-selective catalytic reduction of NOx over a V2O5–WO3/TiO2 catalyst is the major control method of NOx and has been successfully promoted and applied in various large steel enterprises in China. The production of waste catalysts (hazardous waste) from flue gas denitrification in iron and steel enterprises increases annually. Harmless landfills and wet purification are widely-employed methods for the treatment of waste catalysts. However, these methods pose environmental problems such as resource wastefulness, excessive amounts of acid/alkali, and considerable secondary pollution. Optimizing the effective use and disposal of such waste catalysts has become a key common problem in the industry. In this work, a novel method for producing titanium-bearing pellets by adding waste catalysts to pellet material was introduced. The feasibility of using waste catalysts to prepare titanium-bearing pellets was comprehensively evaluated by comparing the preparation process and metallurgical properties of the resulting pellets with those of commercially available titanium-containing pellets. The findings of this study reveal that the addition of 5.0% waste catalyst to the raw material can substantially improve the overall comprehensive performance of green pellets. Moreover, the drop number (dropped from 0.5 m height), average compressive strength, and burst temperature of the green pellets increased from 3.8 times, 16.5 N, and 487 ℃ (without waste catalyst addition) to 7.7 times, 21.5 N, and 553 ℃, clearly outperforming the ordinary titanium-bearing pellets prepared using vanadium–titanium magnetite (1.4 times, 15.0 N, and 542 ℃). These results could be attributed to the physical properties of the waste catalyst, which is a porous material with abundant hydrophilic groups on the surface. These hydrophilic groups, comprising hydroxyl groups, lead to the presence of more capillary water on the catalyst particle surfaces. Furthermore, the capillary force played an important role in various interactions in the pelleting process, thus improving the performance of mixtures. After roasting, the average compressive strength of the pellets containing the waste catalyst was 3083 N, higher than the 2630 N for ordinary titanium-bearing pellets. However, the short preheating and roasting time resulted in partially unreacted TiO2 being present in the internal pores of the pellets as rutile-type particles. The consolidation mechanism of pellets containing waste catalysts demonstrated that TiO2 in the waste catalyst reacts with iron oxide to form a Fe2TiO5 bond, while unreacted TiO2 reduces the compressive strength of the pellets. The metallurgical properties of the two titanium-bearing pellets are virtually identical to those of ordinary oxidized pellets, indicating that the pellets containing waste catalysts can be used in blast furnace protection smelting. This study offers a new approach for recycling waste catalysts generated by flue gas denitrification in iron and steel enterprises.

-

表 1 含鐵原料主要化學成分(質量分數)

Table 1. Main chemical compositions of iron-containing raw materials

% Raw material TFe FeO SiO2 CaO MgO Al2O3 TiO2 V2O5 K2O Na2O MCa 65.75 26.50 6.57 0.30 0.48 0.84 — — — — VTMb 53.62 30.91 3.73 0.98 2.96 3.35 12.17 0.53 — — Bentonite 2.21 69.43 2.50 2.21 17.40 — — 2.48 2.77 MC a: Magnetite concentrate; VTM b: Vanadium titanomagnetite. 表 2 含鐵原料粒度組成(質量分數)

Table 2. Particle size composition of iron-containing raw materials

% Raw material Size composition +0.074 mm +0.045–0.074 mm ?0.074 mm ?0.045 mm MC 6.4 13.3 93.6 80.3 VTM 32.8 29.1 67.2 38.1 表 3 廢催化劑及堵塞物飛灰主要化學成分(質量分數)

Table 3. Main chemical composition of the waste catalyst and fly ash %

% TiO2 WO3 SiO2 CaO Al2O3 V2O5 Fe2O3 P2O5 Na2O K2O Sx 87.27 4.66 3.64 1.32 0.87 0.52 0.07 0.15 0.12 0.09 0.43 表 4 不同球團礦RSI指數和密度

Table 4. RSI index and density of different pellets

Scheme Pre-reduction volume/cm3 Reduced volume/cm3 RSI/% Pre-reduction mass/g Pellet density/(g·cm?3) Pellet-1 22.1 24.2 9.6 87.24 3.95 Pellet-2 23.5 25.6 9.1 85.75 3.65 Pellet-3 22.8 24.6 8.1 87.10 3.82 表 5 不同球團礦RI和RDI性能

Table 5. RI and RDI performance of different pellets

Scheme Mass fraction of TFe/% Mass fraction of FeO/% RI/% RDI+6.3/% RDI+3.15/% RDI-0.5/% Pellet-1 64.38 0.75 61.7 92.2 96.3 1.5 Pellet-2 61.07 1.79 63.3 96.6 97.8 1.2 Pellet-3 60.03 1.08 56.4 98.7 98.7 1.7 表 6 不同球團礦熔滴性能

Table 6. Meltdown properties of different roasted pellets

Scheme Ta/℃ Ts/℃ ΔTsa/℃ Tm/℃ Td/℃ ΔTdm/℃ Pellet-1 1157 1198 41 1205 1331 126 Pellet-2 1163 1209 47 1211 1341 130 Pellet-3 1188 1228 40 1238 1339 101 中文字幕在线观看表 7 含廢催化劑球團主要物相EDS結果

Table 7. EDS results of the pellets containing waste catalyst

Scheme Mass fraction/% O Ti Fe V W Si Point 1 35.99 41.27 3.94 0.08 5.71 — Point 2 36.70 2.97 60.32 — — — Point 3 31.57 0.59 67.84 — — — Point 4 44.40 30.66 20.07 0.40 2.98 1.49 -

參考文獻

[1] Yu Y, Zhu T Y, Liu X L. Progress of ultra-low emission technology for key processes of iron and steel industry in China. Iron Steel, 2019, 54(9): 1 doi: 10.13228/j.boyuan.issn0449-749x.20190061于勇, 朱廷鈺, 劉霄龍. 中國鋼鐵行業重點工序煙氣超低排放技術進展. 鋼鐵, 2019, 54(9):1 doi: 10.13228/j.boyuan.issn0449-749x.20190061 [2] Long H M, Ding L, Qian L X, et al. Current situation and development trend of NOx and dioxins emission reduction in sintering flue gas. Chem Ind Eng Prog, 2022, 41(7): 3865龍紅明, 丁龍, 錢立新, 等. 燒結煙氣中NOx和二噁英的減排現狀及發展趨勢. 化工進展, 2022, 41(7):3865 [3] Xing Y, Zhang W B, Su W, et al. Research of ultra-low emission technologies of the iron and steel industry in China. Chin J Eng, 2021, 43(1): 1邢奕, 張文伯, 蘇偉, 等. 中國鋼鐵行業超低排放之路. 工程科學學報, 2021, 43(1):1 [4] Wei J K, Zhang Q, Li Y G. Cause analysis of deactivation of medium temperature SCR denitration catalyst in sintering machine. Hebei Metall, 2021(12): 75韋晉科, 張強, 李永光. 燒結機中溫SCR脫硝催化劑失活原因分析. 河北冶金, 2021(12):75 [5] Ding L, Qian L X, Yang T, et al. Influence of Zn in the iron ore sintering flue gas on the removal of NOx and dioxins by V2O5–WO3/TiO2 catalyst. Chin J Eng, 2021, 43(8): 1125丁龍, 錢立新, 楊濤, 等. 燒結煙氣中Zn對V2O5-WO3/TiO2催化劑脫除NOx和二噁英性能的影響. 工程科學學報, 2021, 43(8):1125 [6] Hou X J, Zhang X M, Cheng W B, et al. Research on disposal methods of spent vanadium-titanium-based catalysts. Chem Ind Eng Prog, 2021, 40(10): 5313 doi: 10.16085/j.issn.1000-6613.2021-0568侯學軍, 章小明, 程文博, 等. 廢釩鈦基SCR催化劑的處置方法研究進展. 化工進展, 2021, 40(10):5313 doi: 10.16085/j.issn.1000-6613.2021-0568 [7] Long H M, Ding L, Tao J J, et al. Analysis on resource utilization of waste vanadium-tungsten-titanium catalyst for denitration of sintering flue gas. Iron Steel, 2022, 57(7): 162龍紅明, 丁龍, 陶家杰, 等. 燒結煙氣脫硝廢棄釩鎢鈦催化劑資源化利用途徑分析. 鋼鐵, 2022, 57(7):162 [8] Li M, Liu B, Wang X R, et al. A promising approach to recover a spent SCR catalyst: Deactivation by arsenic and alkaline metals and catalyst regeneration. Chem Eng J, 2018, 342: 1 doi: 10.1016/j.cej.2017.12.132 [9] Liu X Y, Jia Y Y, Tang Z H, et al. Research progress on regeneration of waste SCR denitration catalyst. Appl Chem Ind, 2020, 49(7): 1839 doi: 10.3969/j.issn.1671-3206.2020.07.052劉興譽, 賈媛媛, 唐中華, 等. 廢舊SCR脫硝催化劑再生研究進展. 應用化工, 2020, 49(7):1839 doi: 10.3969/j.issn.1671-3206.2020.07.052 [10] He C, Wang L L, Yang X N, et al. Effects of spent SCR catalyst blending on the de-NOx activity of new catalyst. Chem Ind Eng Prog, 2018, 37(2): 581 doi: 10.16085/j.issn.1000-6613.2017-0873何川, 王樂樂, 楊曉寧, 等. 廢棄選擇性催化還原催化劑混摻對新催化劑脫硝性能的影響. 化工進展, 2018, 37(2):581 doi: 10.16085/j.issn.1000-6613.2017-0873 [11] Erust C, Akcil A, Bedelova Z, et al. Recovery of vanadium from spent catalysts of sulfuric acid plant by using inorganic and organic acids: Laboratory and semi-pilot tests. Waste Manag, 2016, 49: 455 doi: 10.1016/j.wasman.2015.12.002 [12] Liu L J, Wang L L, Su S, et al. Leaching behavior of vanadium from spent SCR catalyst and its immobilization in cement-based solidification/stabilization with sulfurizing agent. Fuel, 2019, 243: 406 doi: 10.1016/j.fuel.2019.01.160 [13] Zhou H, Guo X T, Zhou M X. Influence of different additives on harmless melting treatment of waste SCR catalysts. J Chin Soc Power Eng, 2017, 37(12): 999 doi: 10.3969/j.issn.1674-7607.2017.12.009周昊, 國旭濤, 周明熙. 不同添加劑對廢棄SCR催化劑熔融無害化處理的影響. 動力工程學報, 2017, 37(12):999 doi: 10.3969/j.issn.1674-7607.2017.12.009 [14] Zhou H, Ma P N, Lai Z Y, et al. Harmless treatment of waste selective catalytic reduction catalysts during iron ore sintering process. J Clean Prod, 2020, 275: 122954 doi: 10.1016/j.jclepro.2020.122954 [15] Qian L X, Yang T, Long H M, et al. Recycling of waste V2O5–WO3/TiO2 catalysts in the iron ore sintering process via a preballing approach. ACS Sustainable Chem Eng, 2021, 9(48): 16373 doi: 10.1021/acssuschemeng.1c06271 [16] Liu D H, Wang X Z, Zhang J L, et al. Application status and investigation of titanium-containing materials in blast furnace protection process. China Metall, 2018, 28(2): 1劉東輝, 王曉哲, 張建良, 等. 高爐護爐用含鈦物料應用現狀及調研分析. 中國冶金, 2018, 28(2):1 [17] Wu J L, Chen H, Sun J, et al. Metallurgical properties and furnace protection practice of different titanium-bearing burdens. Ironmak Steelmak, 2020, 47(10): 1161 doi: 10.1080/03019233.2019.1678845 [18] Sun J, Wang S, Chu M S, et al. Titanium distribution between blast furnace slag and iron for blast furnace linings protection. Ironmak Steelmak, 2020, 47(5): 545 doi: 10.1080/03019233.2018.1557847 [19] Zhao H, Bennici S, Shen J, et al. The influence of the preparation method on the structural, acidic and redox properties of V2O5-TiO2/SO42? catalysts. Appl Catal A Gen, 2009, 356(2): 121 doi: 10.1016/j.apcata.2008.12.037 [20] Forsmo S P E, Samskog P O, Bj?rkman B M T. A study on plasticity and compression strength in wet iron ore green pellets related to real process variations in raw material fineness. Powder Technol, 2008, 181(3): 321 doi: 10.1016/j.powtec.2007.05.023 [21] Chen X L, Huang Y S, Fan X H, et al. Oxidation roasting behavior and concretion properties of vanadium-titanium magnetite pellet. J Central South Univ (Sci Technol), 2016, 47(2): 359陳許玲, 黃云松, 范曉慧, 等. 釩鈦磁鐵礦球團氧化焙燒行為和固結特性. 中南大學學報(自然科學版), 2016, 47(2):359 [22] Gan M, Sun Y F, Fan X H, et al. Preparing high-quality vanadium titano-magnetite pellets for large-scale blast furnaces as ironmaking burden. Ironmak Steelmak, 2020, 47(2): 130 doi: 10.1080/03019233.2018.1492500 [23] Chen X L, Gan M, Fan X H, et al. Concretion properties of organic-binder oxidate pellets and strengthen measures. J Central South Univ (Sci Technol), 2009, 40(3): 550陳許玲, 甘敏, 范曉慧, 等. 有機粘結劑氧化球團固結特性及強化措施. 中南大學學報(自然科學版), 2009, 40(3):550 [24] Cheng G J, Xing Z X, Yang H, et al. Effects of high proportion unground sea sand ore on the preparation process and reduction performance of oxidized pellets. Minerals, 2021, 11(1): 87 doi: 10.3390/min11010087 [25] Cristallo G, Roncari E, Rinaldo A, et al. Study of anatase–rutile transition phase in monolithic catalyst V2O5/TiO2 and V2O5–WO3/TiO2. Appl Catal A Gen, 2001, 209(1-2): 249 doi: 10.1016/S0926-860X(00)00773-0 [26] Nova I, Dall’Acqua L, Lietti L, et al. Study of thermal deactivation of a de-NOx commercial catalyst. Appl Catal B Environ, 2001, 35(1): 31 doi: 10.1016/S0926-3373(01)00229-6 -

下載:

下載: