Application of expert-augmented machine learning modeling in high-strength and high-conductivity copper alloy development

-

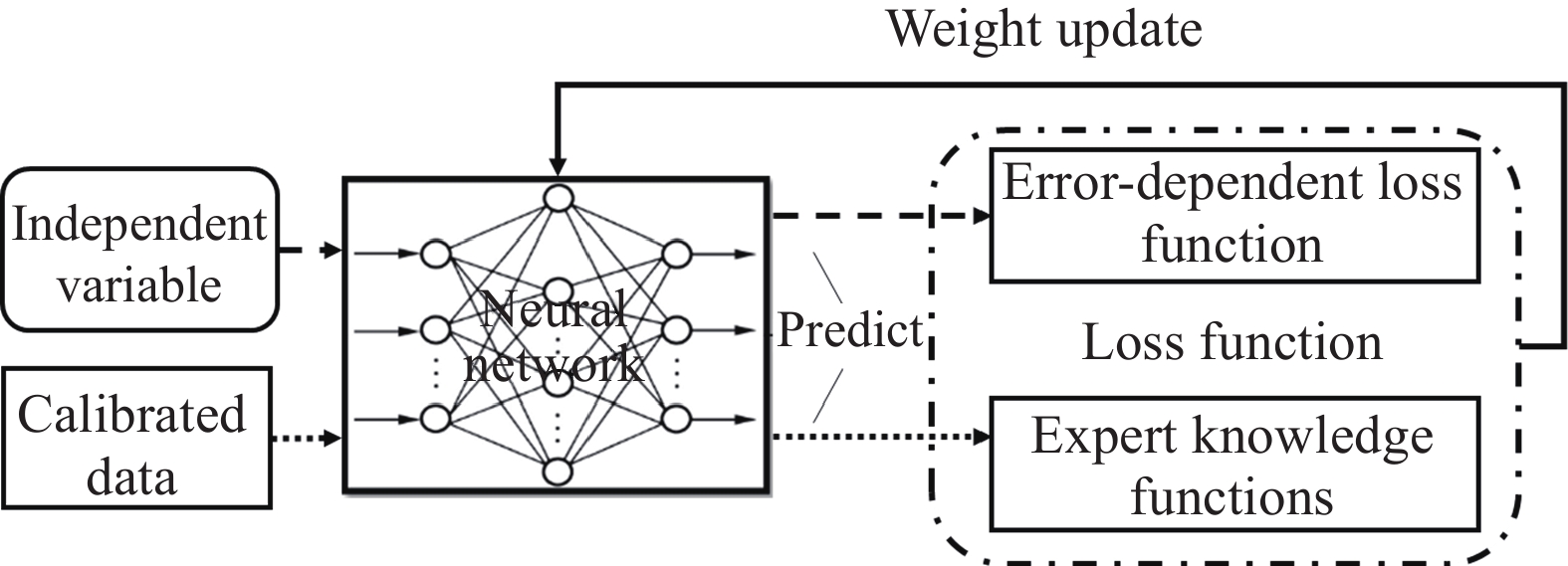

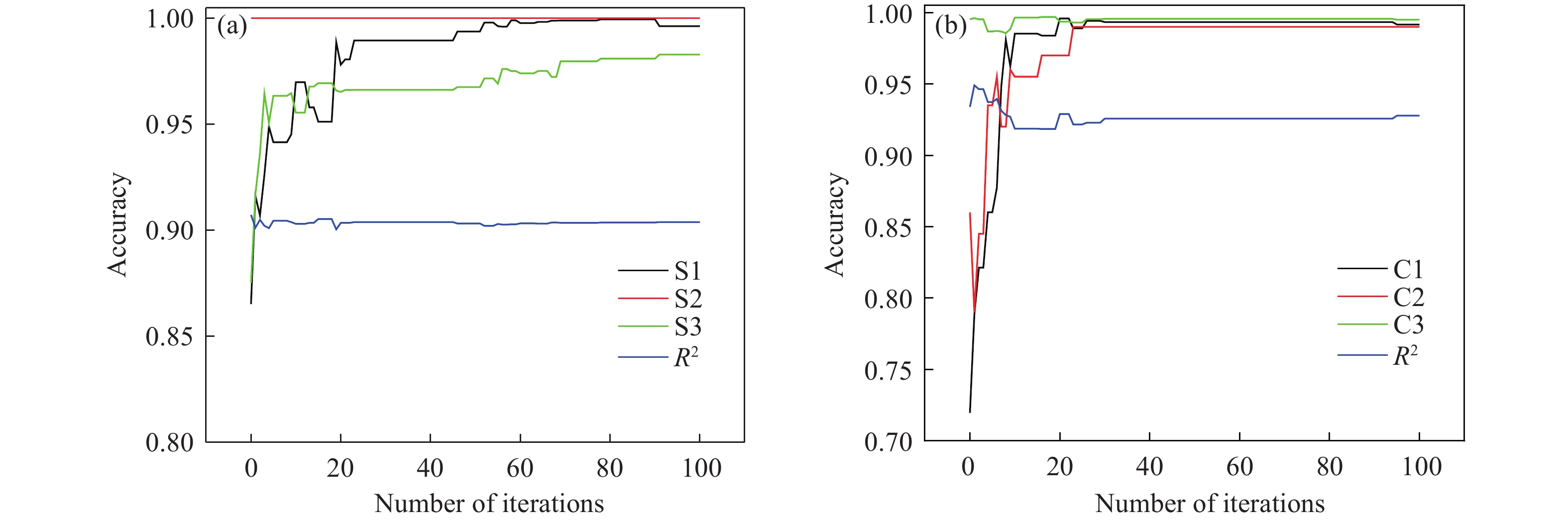

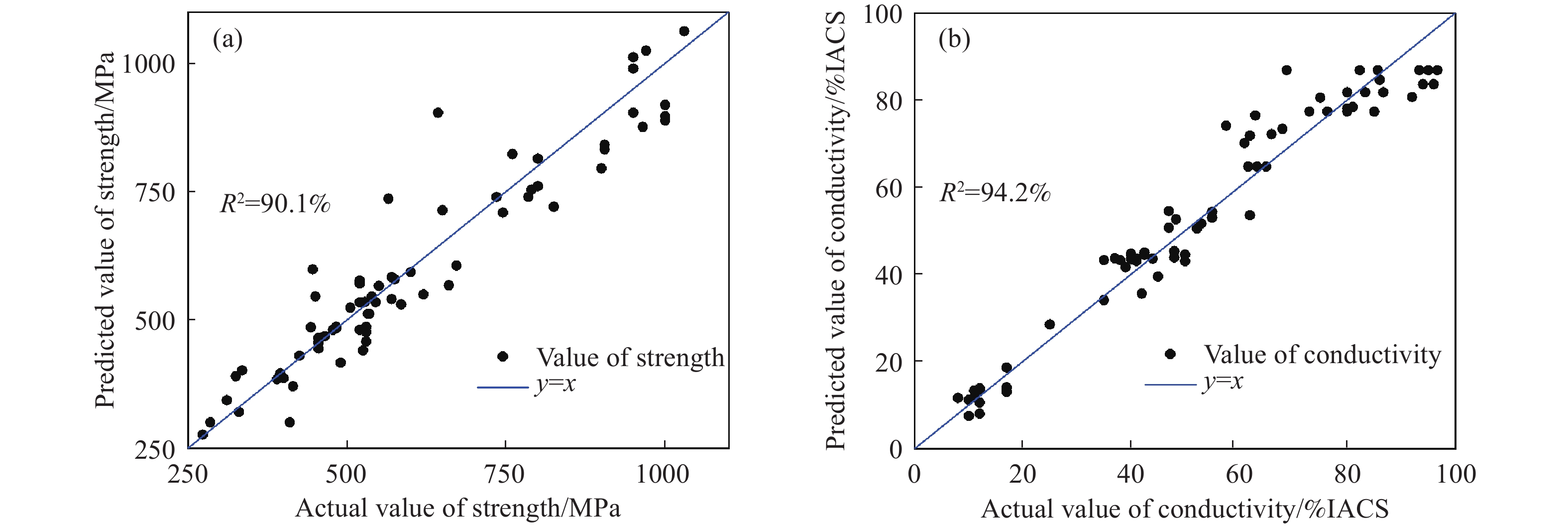

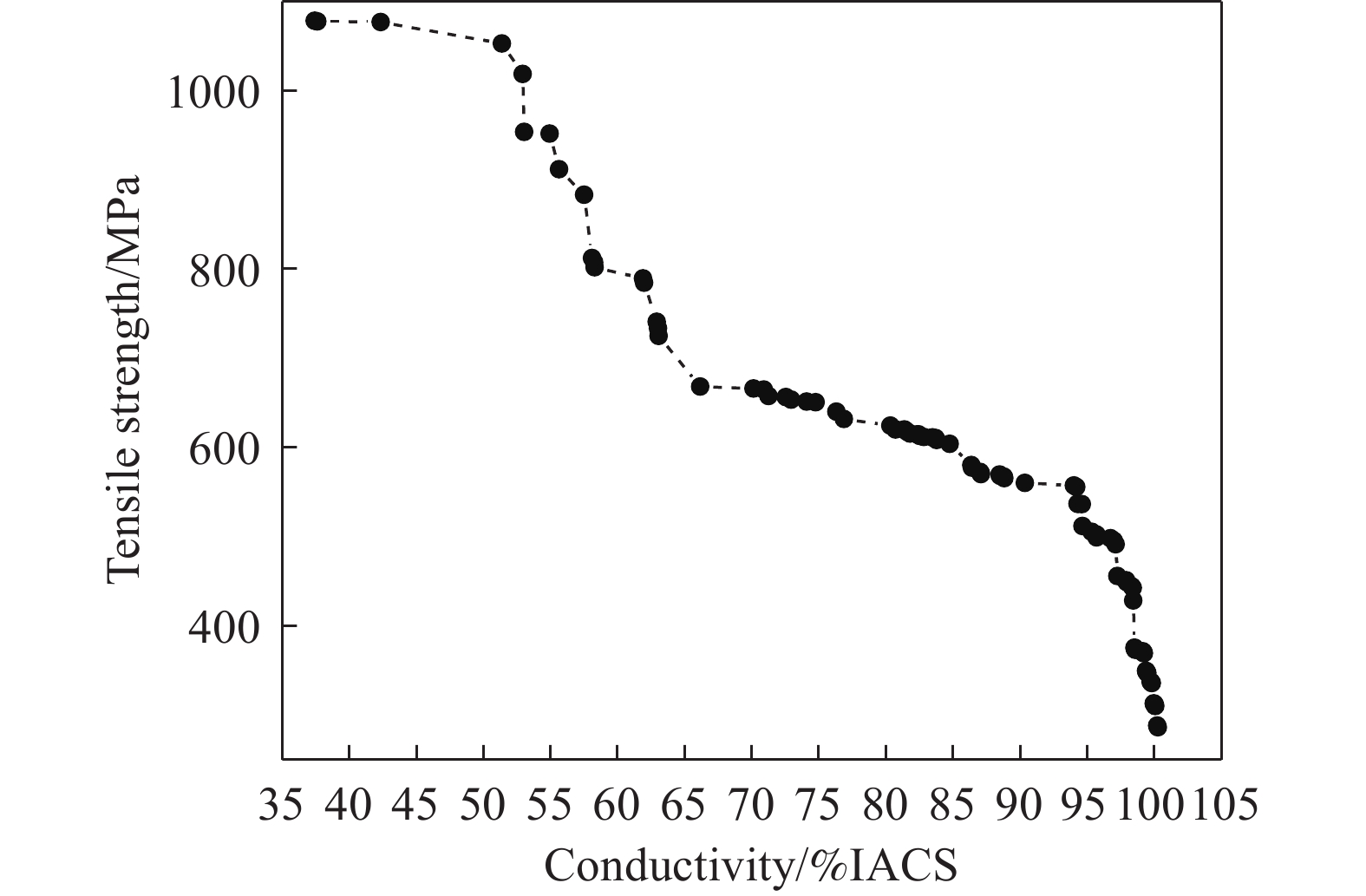

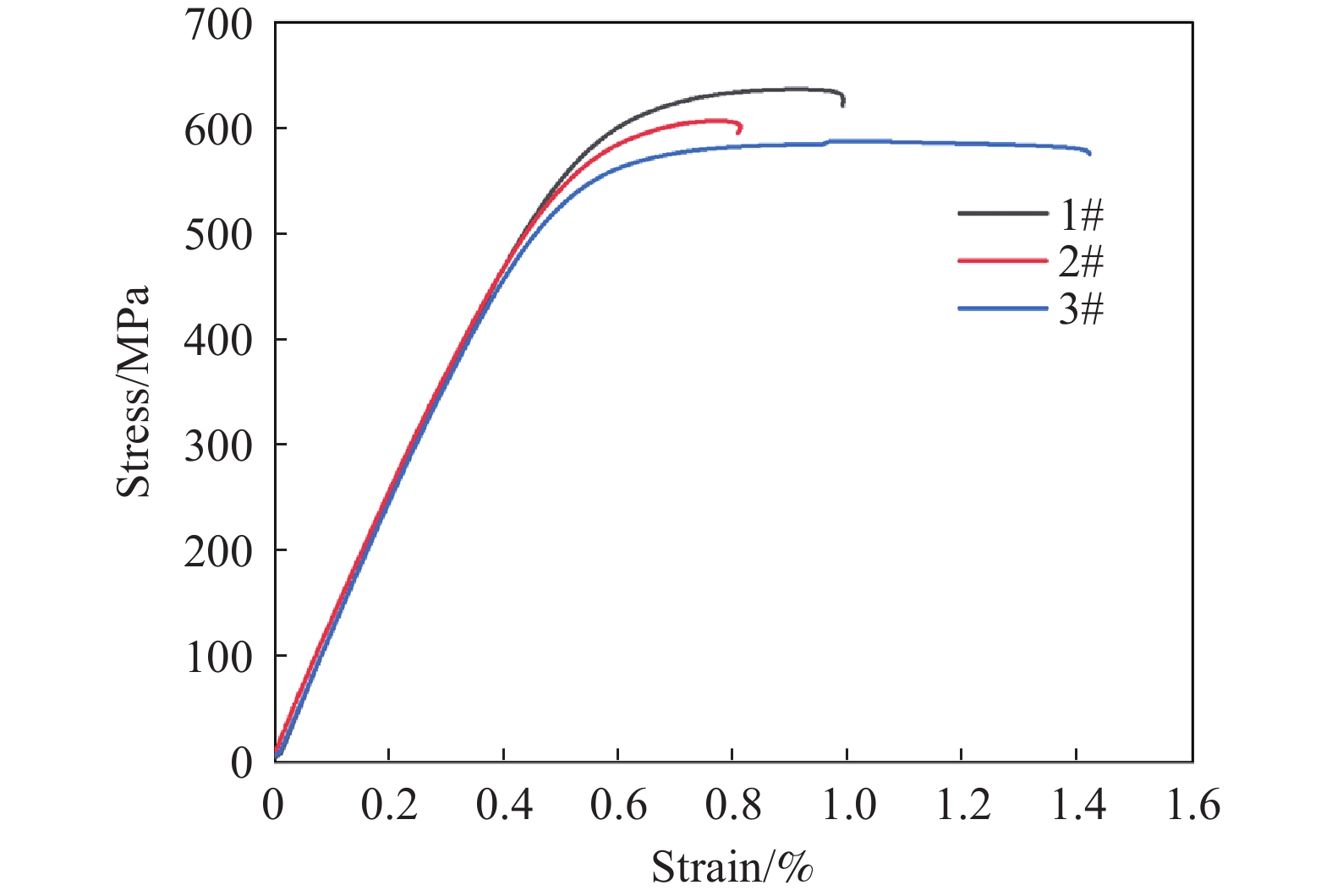

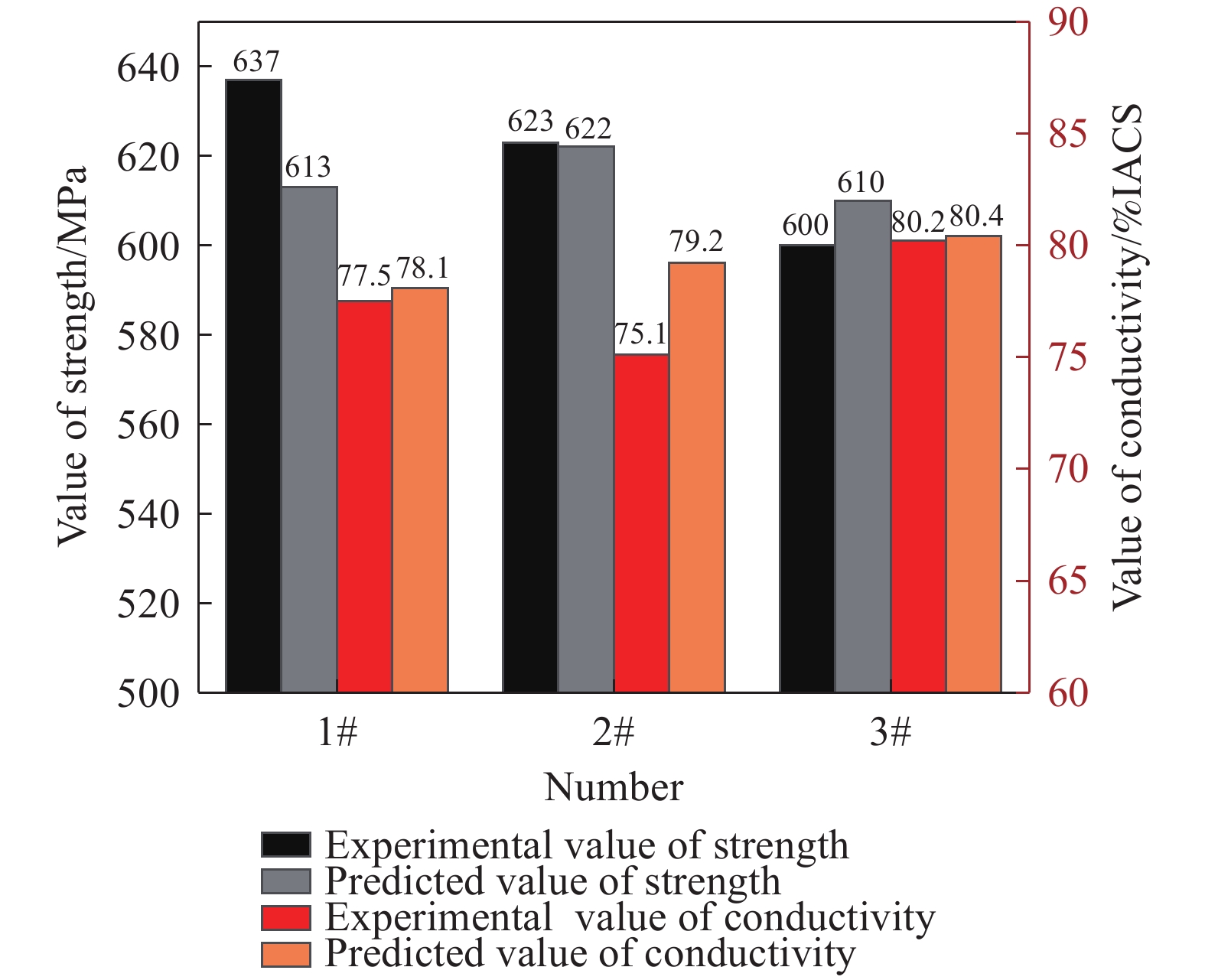

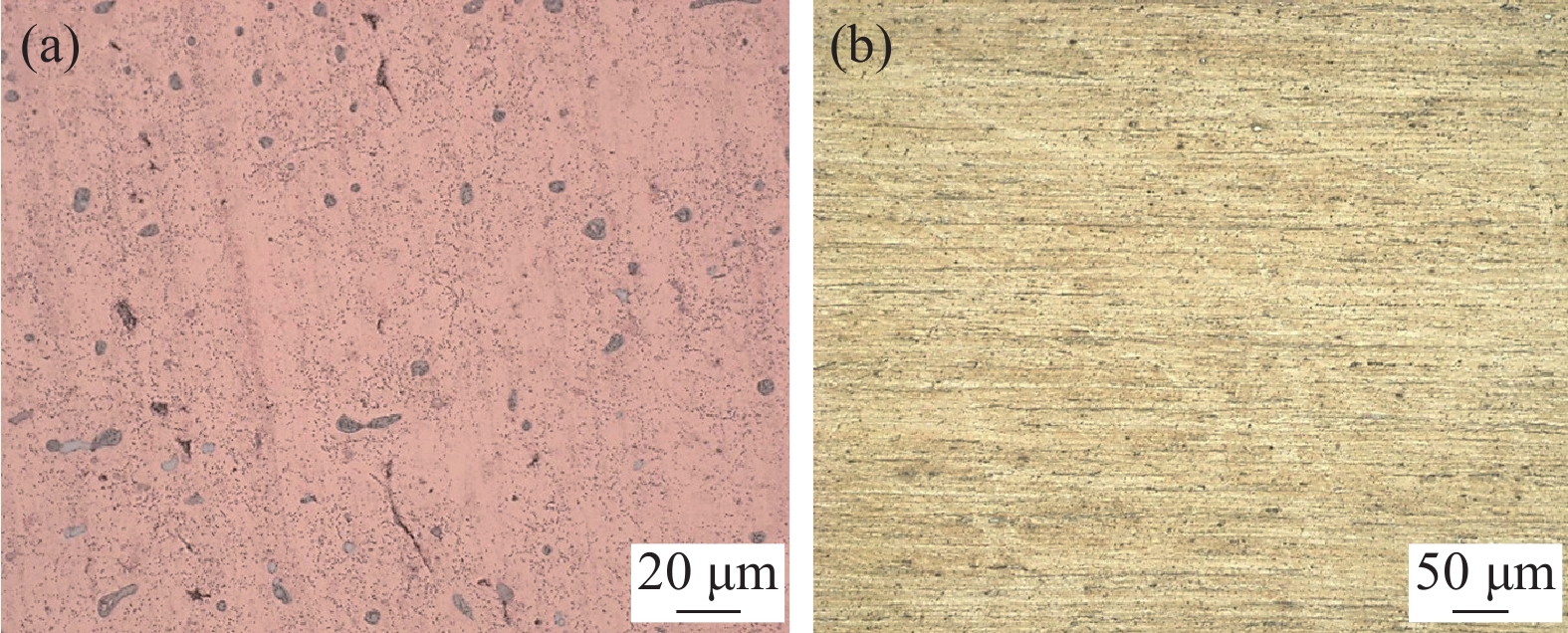

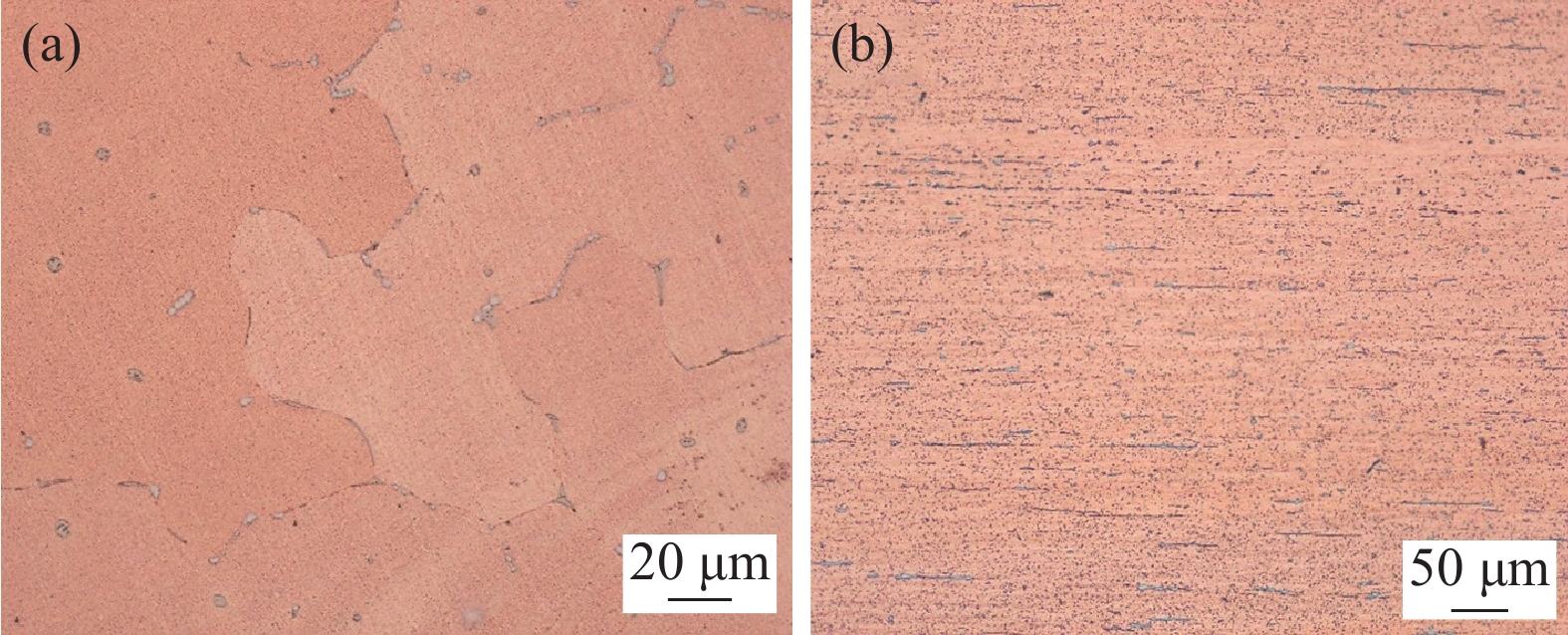

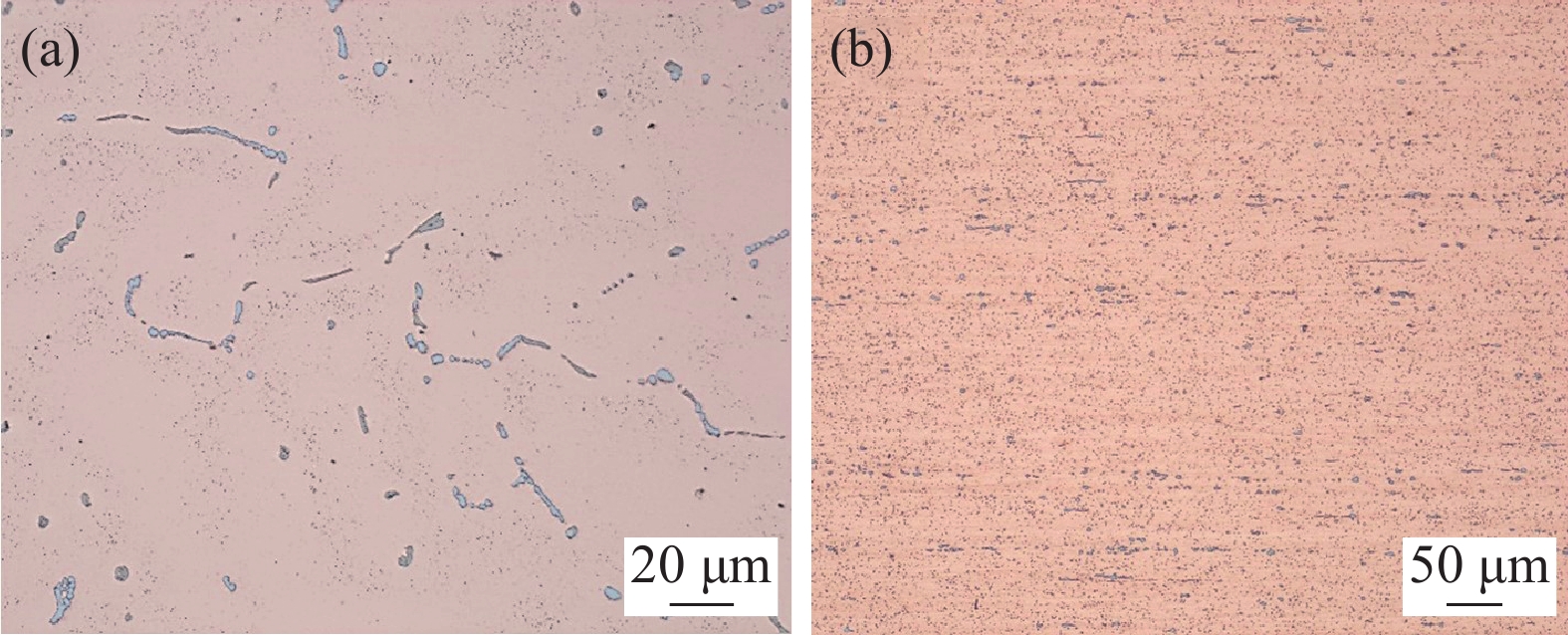

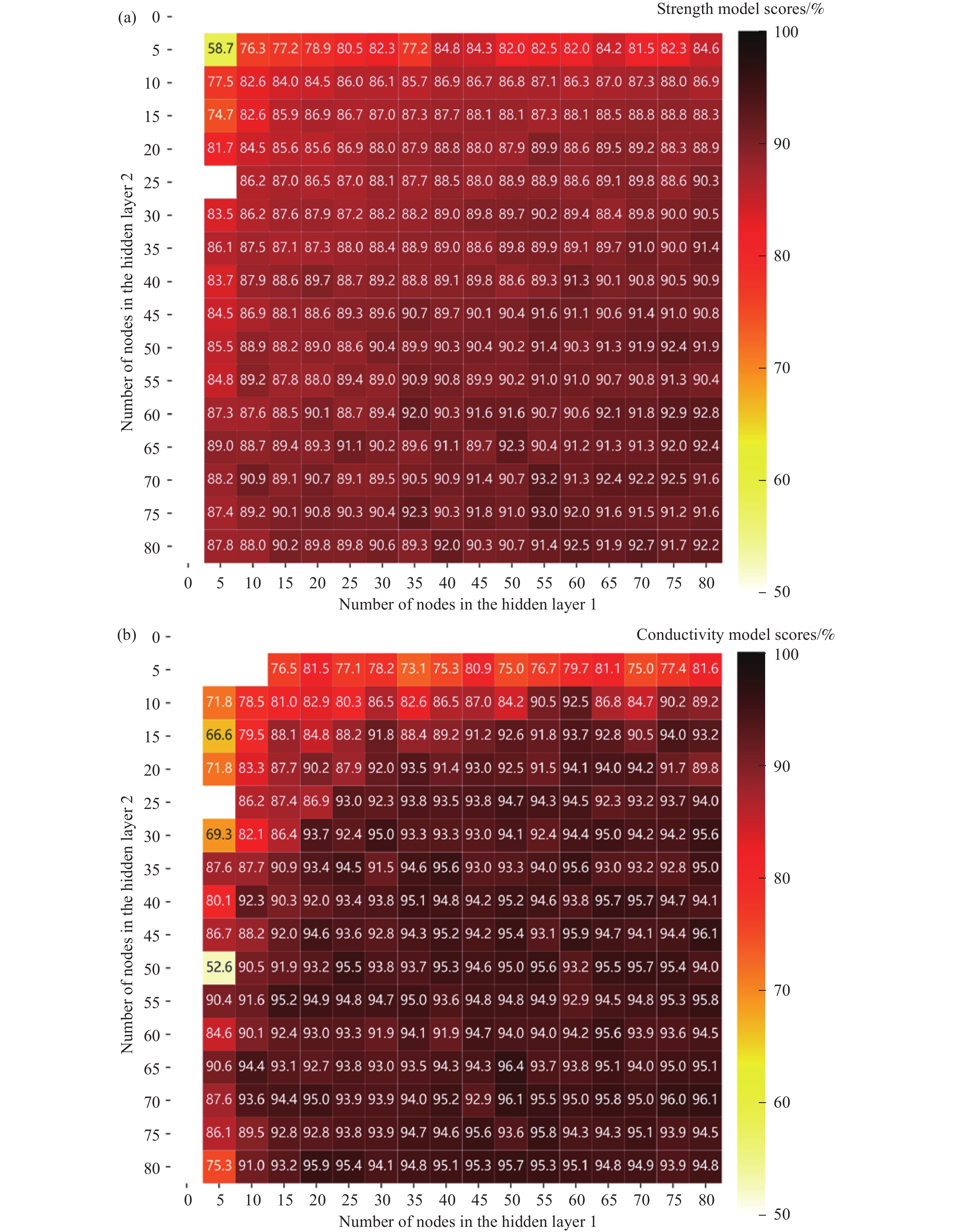

摘要: 材料領域數據具有小樣本、噪聲大、維度高、關系復雜、專家知識豐富的特點. 利用專家知識增強機器學習建模效果具有必要性和可行性. 本文通過計算自變量與因變量之間的秩相關系數,來定量描述成分狀態因素與性能之間單調關系的強弱. 在模型訓練過程中,將秩相關系數加入到神經網絡損失函數,實時評估模型輸出與專家知識的相符程度,得到了專家知識增強的機器學習模型. 對訓練過程分析后發現,模型輸出的合理性有顯著提升,模型的輸入輸出規律與專家知識的相符程度達到了0.98以上(1.0為完全相符). 基于所建模型,采用遺傳算法進行了關于強度和導電率的多目標優化,找到了滿足帕累托最優的高強高導銅合金成分并開展了實驗驗證. 實驗結果表明,強度在高達637 MPa的同時,導電率仍能保持在77.5% IACS(國際退火銅標準)的水平;導電率高達80.2% IACS的同時,強度仍能保持在600 MPa的水平. 強度和導電率的預測值與實際值誤差在5%以內.Abstract: Investigation into material data is frequently limited by small sample sizes, high noise levels, complex associations, high dimensionality, and the need for expert knowledge. To improve the effectiveness of machine learning modeling, incorporating expert knowledge is necessary. In this study, we assembled a dataset including 410 data points containing composition, condition, and property data, in which the state symbols of the copper alloy were recoded using the one-hot encoding method. Because of the substantial capacity of neural network algorithms for powerful nonlinear fitting, we employed these algorithms for modeling. The network structures of the strength and conductivity models were optimized to 21–55–70–1 and 21–50–65–1, respectively. After optimizing the network structure, expert knowledge was integrated into the neural network loss function. This approach quantitatively describes the strength of the monotonic relations between the status factors of components and performance by calculating the rank correlation coefficient between the independent and dependent variables. During model training, the rank correlation coefficient was incorporated into the neural network loss function to assess the similarity between the model output and expert knowledge in real-time. For instance, the relation in which strength increases with the hardening level was quantitatively expressed with a Spearman score, and these Spearman scores were added to the loss function. A machine learning model augmented by expert knowledge was trained using genetic algorithm-based optimization of network weights. After updating each network weight, orthogonal data were generated to evaluate the consistency between output data and expert knowledge. The Spearman correlation coefficients between the model input–output data and expert knowledge exceeded 0.98, and the R2 scores of the strength and conductivity models achieved on the test set were >0.90. Multiobjective optimization based on composition, condition, strength, and conductivity models was conducted using a genetic algorithm, and Pareto-optimal solutions were obtained and experimentally validated after 100 generations of iteration. Three sets of components were selected from the Pareto-optimal solutions and were empirically tested for validation. The results showed that the tensile strength had reached 637 MPa, while conductivity was maintained at 77.5% IACS (International annealing copper standard), and when the conductivity was 80.2% IACS, the tensile strength was 600 MPa. The relative errors between the experimental and predicted values were <5%. Microstructure images of three experimental sample sets demonstrated that coarse second phases were present in the as-cast structure; however, these structures were dissolved and redistributed after the solid solution, cold deformation, and aging processes. The precipitated particles distributed along the grain boundary had low strength and conductivity. Our analysis revealed that the Mg and Ti elements were detrimental to the increase in strength, while Fe and Sn effectively increased strength. Additionally, Fe had a lower impact on conductivity than Sn. The results of this study demonstrate that the three optimized components identified can satisfy the performance requirements of interconnected frameworks in ultralarge-scale integrated circuits.

-

表 1 成分質量分數與性能的描述統計

Table 1. Statistical description of the composition mass fraction (%) and property data

Variables Indicators Avg Std Min Max Count of

nonzero valuew(Mn) /% 0.026 0.11 0 0.5 32 w(Fe)/% 0.19 0.49 0 2.35 103 w(Ti)/% 0.16 0.67 0 3.2 61 w(Co)/% 0.07 0.29 0 1.9 45 w(P)/% 0.02 0.05 0 0.2 159 w(Zr)/% 0.01 0.05 0 0.4 64 w(Sn)/% 0.86 2.06 0 10 208 w(Cr)/% 0.05 0.17 0 1.02 74 w(Zn)/% 0.67 3.06 0 22.46 83 w(Mg)/% 0.04 0.12 0 0.7 101 w(Si)/% 0.15 0.26 0 0.925 120 w(Ni)/% 1.6 3.59 0 21 174 w(Ag)/% 0.002 0.02 0 0.2 12 w(Al)/% 0.05 0.42 0 3.5 14 w(Te)/% 0.0003 0.003 0 0.02 12 UTS/MPa 623 211 248 1450 410 EC/%IACS 55 27 3 102 410 表 2 銅合金狀態代號的編碼映射表(部分)

Table 2. Coding schedule of copper alloy condition symbols (partial)

Material designation and

its meaningFeatures and their values after recoding Hardened level/% Immediate quenching Precipitation hardening Order hardening Stress relieving Annealed H00 1/8 Hard 5 0 0 0 0 0 H01 1/4 Hard 10 0 0 0 0 0 H04 Hard 37.1 0 0 0 0 0 TM00 heat-treated, 1/8 Hard 5 1 0 0 0 0 TM01 heat-treated, 1/4 Hard 10 1 0 0 0 0 TM06 heat-treated, extra hard 50 1 0 0 0 0 TR01 precipitation hardening, stress

relieving, 1/4 Hard10 0 1 0 1 0 HT04 order-hardening, Hard 37.1 0 0 1 0 0 O Annealed 0 0 0 0 0 1 表 3 校驗數據生成和平均Spearman系數計算示例(H: 硬化程度; P_EC: 導電率預測值)

Table 3. A demo for checking data generation and calculating the average Spearman correlation coefficient values (H: Hardened level; P_EC: Predicted value of EC)

No. Ni mass fraction/% Si mass fraction/% Ti mass fraction/% ··· H/% P_EC/%IACS Absolute value of spearman

scores between H and P_EC1 0 0.1 0.1 ··· 0 80 0.8 2 0 0.1 0.1 ··· 15 85 3 0 0.1 0.1 ··· 30 65 4 0 0.1 0.1 ··· 45 50 5 0 0.1 0.1 ··· 60 54 6 0.2 0.3 0.2 ··· 0 84 0.9 7 0.2 0.3 0.2 ··· 15 73 8 0.2 0.3 0.2 ··· 30 37 9 0.2 0.3 0.2 ··· 45 40 10 0.2 0.3 0.2 ··· 60 35 11 0.4 0.2 0.3 0 24 ··· ··· ··· ··· ··· ··· ··· ··· Average 0.92 中文字幕在线观看表 4 優化出的高強高導銅合金成分及預測性能

Table 4. Compositions and predicted properties of the optimized high-strength and high-conductivity copper alloys

No. Composition(mass fraction)/% Predicted properties UTS/MPa EC/%IACS 1# Cu–0.5Cr–0.2Zr–0.1Mg–0.05Ti–0.06Fe 613 78.1 2# Cu–0.6Cr–0.15Zr–0.1Mg–0.02Ti–0.05Sn 635 77.2 3# Cu–0.6Cr–0.1Zr–0.1Mg–0.02Ti 607 83.4 -

參考文獻

[1] Xie J X, Su Y J, Xue D Z, et al. Machine learning for materials research and development. Acta Metall Sin, 2021, 57(11): 1343謝建新, 宿彥京, 薛德禎, 等. 機器學習在材料研發中的應用. 金屬學報, 2021, 57(11):1343 [2] Agrawal A, Choudhary A. Perspective: Materials informatics and big data: Realization of the “fourth paradigm” of science in materials science. APL Mater, 2016, 4(5): 053208 doi: 10.1063/1.4946894 [3] Liu Y L, Niu C, Wang Z, et al. Machine learning in materials genome initiative: A review. J Mater Sci Technol, 2020, 57: 113 doi: 10.1016/j.jmst.2020.01.067 [4] Hart G L W, Mueller T, Toher C, et al. Machine learning for alloys. Nat Rev Mater, 2021, 6(8): 730 doi: 10.1038/s41578-021-00340-w [5] Chen C, Zuo Y X, Ye W K, et al. A critical review of machine learning of energy materials. Adv Energy Mater, 2020, 10(8): 1903242 doi: 10.1002/aenm.201903242 [6] Raccuglia P, Elbert K C, Adler P D F, et al. Machine-learning-assisted materials discovery using failed experiments. Nature, 2016, 533(7601): 73 doi: 10.1038/nature17439 [7] Janet J P, Chan L, Kulik H J. Accelerating chemical discovery with machine learning: Simulated evolution of spin crossover complexes with an artificial neural network. J Phys Chem Lett, 2018, 9(5): 1064 doi: 10.1021/acs.jpclett.8b00170 [8] Torkamannia A, Omidi Y, Ferdousi R. A review of machine learning approaches for drug synergy prediction in cancer. Brief Bioinform, 2022, 23(3): bbac075 doi: 10.1093/bib/bbac075 [9] Zheng W D, Zhang H R, Hu H Q, et al. Performance prediction of perovskite materials based on different machine learning algorithms. Chin J Nonferrous Met, 2019, 29(4): 803鄭偉達, 張惠然, 胡紅青, 等. 基于不同機器學習算法的鈣鈦礦材料性能預測. 中國有色金屬學報, 2019, 29(4):803 [10] Balachandran P V, Emery A A, Gubernatis J E, et al. Predictions of new ABO3 perovskite compounds by combining machine learning and density functional theory. Phys Rev Materials, 2018, 2(4): 043802 doi: 10.1103/PhysRevMaterials.2.043802 [11] She C L, Huang Q C, Chen C, et al. Machine learning-guided search for high-efficiency perovskite solar cells with doped electron transport layers. J Mater Chem A, 2021, 9(44): 25168 doi: 10.1039/D1TA08194B [12] Sun Y T, Bai H Y, Li M Z, et al. Machine learning approach for prediction and understanding of glass-forming ability. J Phys Chem Lett, 2017, 8(14): 3434 doi: 10.1021/acs.jpclett.7b01046 [13] Xiong J E, Zhang T Y, Shi S Q. Machine learning prediction of elastic properties and glass-forming ability of bulk metallic glasses. MRS Commun, 2019, 9(2): 576 doi: 10.1557/mrc.2019.44 [14] Xu Y, Zhang Y F, Gao T, et al. Parameters analysis of Al-based amorphous alloys using support vector regression. Chin J Nonferrous Met, 2016, 26(4): 836徐燕, 張玉鳳, 高湉, 等. Al基非晶合金表征參數的支持向量回歸分析. 中國有色金屬學報, 2016, 26(4):836 [15] Wang J, Xiao B, Liu Y. Machine learning assisted high-throughput experiments accelerates the composition design of hard high-entropy alloy CoxCryTizMouWv. Mater China, 2020, 39(4): 269王炯, 肖斌, 劉軼. 機器學習輔助的高通量實驗加速硬質高熵合金CoxCryTizMouWv成分設計. 中國材料進展, 2020, 39(4):269 [16] Rao Z Y, Tung P Y, Xie R W, et al. Machine learning-enabled high-entropy alloy discovery. Science, 2022, 378(6615): 78 doi: 10.1126/science.abo4940 [17] Klimenko D, Stepanov N, Li J A, et al. Machine learning-based strength prediction for refractory high-entropy alloys of the Al–Cr–Nb–Ti–V–Zr system. Materials, 2021, 14(23): 7213 doi: 10.3390/ma14237213 [18] Wang C S, Fu H D, Jiang L, et al. A property-oriented design strategy for high performance copper alloys via machine learning. NPJ Comput Mater, 2019, 5: 87 doi: 10.1038/s41524-019-0227-7 [19] Zhang H T, Fu H D, He X Q, et al. Dramatically enhanced combination of ultimate tensile strength and electric conductivity of alloys via machine learning screening. Acta Mater, 2020, 200: 803 doi: 10.1016/j.actamat.2020.09.068 [20] Wu S W, Zhou X G, Ren J K, et al. Optimal design of hot rolling process for C–Mn steel by combining industrial data-driven model and multi-objective optimization algorithm. J Iron Steel Res Int, 2018, 25(7): 700 doi: 10.1007/s42243-018-0101-8 [21] Qiu H D, Tian J Y, Wang S Y, et al. Modeling method of fuzzy neural network and its application in rolling force control. China Metall, 2021, 31(1): 52邱華東, 田建艷, 王書宇, 等. 模糊神經網絡融合建模方法及其在軋制力控制中的應用. 中國冶金, 2021, 31(1):52 [22] Asif K, Zhang L, Derrible S, et al. Machine learning model to predict welding quality using air-coupled acoustic emission and weld inputs. J Intell Manuf, 2022, 33(3): 881 doi: 10.1007/s10845-020-01667-x [23] Hart-Rawung T, Buhl J, Bambach M. A fast approach for optimization of hot stamping based on machine learning of phase transformation kinetics. Procedia Manuf, 2020, 47: 707 doi: 10.1016/j.promfg.2020.04.218 [24] Su Y J, Fu H D, Bai Y, et al. Progress in materials genome engineering in China. Acta Metall Sin, 2020, 56(10): 1313宿彥京, 付華棟, 白洋, 等. 中國材料基因工程研究進展. 金屬學報, 2020, 56(10):1313 [25] Raissi M. Deep hidden physics models: Deep learning of nonlinear partial differential equations. J Mach Learn Res, 2018, 19: 1 [26] Sun L N, Gao H, Pan S W, et al. Surrogate modeling for fluid flows based on physics-constrained deep learning without simulation data. Comput Methods Appl Mech Eng, 2020, 361: 112732 doi: 10.1016/j.cma.2019.112732 [27] Sang L, Xu M, Qian S S, et al. Knowledge graph enhanced neural collaborative filtering with residual recurrent network. Neurocomputing, 2021, 454: 417 doi: 10.1016/j.neucom.2021.03.053 [28] Chai X Q. Diagnosis method of thyroid disease combining knowledge graph and deep learning. IEEE Access, 2020, 8: 149787 doi: 10.1109/ACCESS.2020.3016676 [29] Heaton J. The number of hidden layers [R/OL]. Heaton Research (2017-06-01) [2022-09-19]. https://www.heatonresearch.com/2017/06/01/hidden-layers.html -

下載:

下載: