| [1] |

Takenaka T, Nagata H. Current status and prospects of lead-free piezoelectric ceramics. J Eur Ceram Soc, 2005, 25(12): 2693 doi: 10.1016/j.jeurceramsoc.2005.03.125

|

| [2] |

Panda P K. Review: environmental friendly lead-free piezoelectric materials. J Mater Sci, 2009, 44(19): 5049 doi: 10.1007/s10853-009-3643-0

|

| [3] |

Li J F, Wang K, Zhu F Y, et al. (K, Na)NbO3-based lead-free piezoceramics: fundamental aspects, processing technologies, and remaining challenges. J Am Ceram Soc, 2013, 96(12): 3677 doi: 10.1111/jace.12715

|

| [4] |

Wu J G, Xiao D Q, Zhu J G. Potassium-sodium niobate lead-free piezoelectric materials: past, present, and future of phase boundaries. Chem Rev, 2015, 115(7): 2559 doi: 10.1021/cr5006809

|

| [5] |

Wei J, Fu D, Cheng J, et al. Temperature dependence of the dielectric and piezoelectric properties of xBiFeO3-(1-x)BaTiO3 ceramics near the morphotropic phase boundary. J Mater Sci, 2017, 52(18): 10726 doi: 10.1007/s10853-017-1280-6

|

| [6] |

Lee M H, Kim D J, Park J S, et al. High-performance lead-free piezoceramics with high Curie temperatures. Adv Mater, 2015, 27(43): 6976 doi: 10.1002/adma.201502424

|

| [7] |

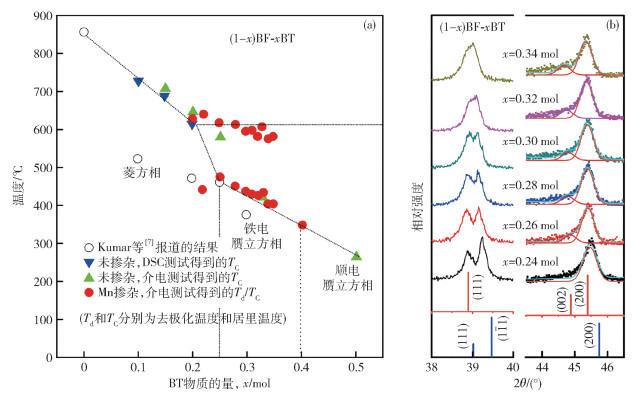

Kumar M M, Srinivas A, Suryanarayana S V. Structure property relations in BiFeO3/BaTiO3 solid solutions. J Appl Phys, 2000, 87(2): 855 doi: 10.1063/1.371953

|

| [8] |

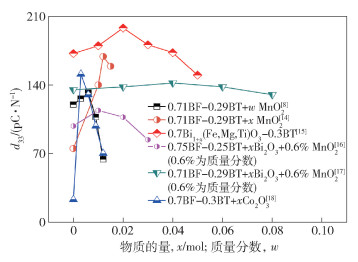

Leontsev S O, Eitel R E. Dielectric and piezoelectric properties in Mn-modified (1-x)BiFeO3-xBaTiO3 ceramics. J Am Ceram Soc, 2009, 92(12): 2957 doi: 10.1111/j.1551-2916.2009.03313.x

|

| [9] |

Wei Y X, Wang X T, Zhu J T, et al. Dielectric, ferroelectric, and piezoelectric properties of BiFeO3-BaTiO3 ceramics. J Am Ceram Soc, 2013, 96(10): 3163 doi: 10.1111/jace.12475

|

| [10] |

Zhu L F, Zhang B P, Zhang Z C, et al. Piezoelectric, ferroelectric and ferromagnetic properties of (1-x)BiFeO3-xBaTiO3 lead-free ceramics near morphotropic phase boundary. J Mater Sci Mater Electron, 2018, 29(3): 2307 doi: 10.1007/s10854-017-8147-0

|

| [11] |

Kim S, Khanal G P, Nam H W, et al. Structural and electrical characteristics of potential candidate lead-free BiFeO3-BaTiO3 piezoelectric ceramics. J Appl Phys, 2017, 122(16): 164105 doi: 10.1063/1.4999375

|

| [12] |

Zhao Y J, Huang R X, Liu R Z, et al. Phase structure of Li0.058(Na0.51K0.49)0.942NbO3 lead-free piezoelectric ceramics. Mater Lett, 2012, 84: 52 doi: 10.1016/j.matlet.2012.06.030

|

| [13] |

Rojac T, Kosec M, Budic B, et al. Strong ferroelectric domain-wall pinning in BiFeO3 ceramics. J Appl Phys, 2010, 108(7): 074107 doi: 10.1063/1.3490249

|

| [14] |

Li Q, Wei J X, Cheng J R, et al. High temperature dielectric, ferroelectric and piezoelectric properties of Mn-modified BiFeO3-BaTiO3 lead-free ceramics. J Mater Sci, 2017, 52(1): 229 doi: 10.1007/s10853-016-0325-6

|

| [15] |

Zhu L F, Zhang B P, Li S, et al. Large piezoelectric responses of Bi(Fe, Mg, Ti)O3-BaTiO3 lead-free piezoceramics near the morphotropic phase boundary. J Alloys Compd, 2017, 727: 382 doi: 10.1016/j.jallcom.2017.08.014

|

| [16] |

Chen J G, Cheng J R. Enhanced thermal stability of lead-free high temperature 0.75BiFeO3-0.25BaTiO3 ceramics with excess Bi content. J Alloys Compd, 2014, 589: 115 doi: 10.1016/j.jallcom.2013.11.169

|

| [17] |

Zhou C, Yang H, Zhou Q, et al. Effects of Bi excess on the structure and electrical properties of high-temperature BiFeO3-BaTiO3 piezoelectric ceramics. J Mater Sci: Mater Electron, 2013, 24(5): 1685 doi: 10.1007/s10854-012-0996-y

|

| [18] |

Huang S G, Li Q N, Yang L, et al. Enhanced piezoelectric properties by reducing leakage current in Co modified 0.7BiFeO3-0.3BaTiO3 ceramics. Ceram Int, 2018, 44(8): 8955 doi: 10.1016/j.ceramint.2018.02.095

|

| [19] |

Yang H B, Zhou C R, Liu X Y, et al. Piezoelectric properties and temperature stabilities of Mn-and Cu-modified BiFeO3-BaTiO3 high temperature ceramics. J Eur Ceram Soc, 2013, 33(6): 1177 doi: 10.1016/j.jeurceramsoc.2012.11.019

|

| [20] |

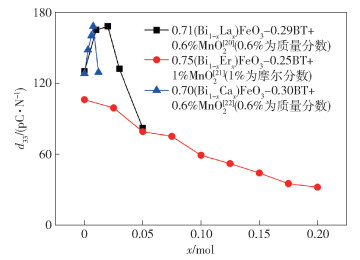

Zhou C R, Yang H B, Zhou Q, et al. Dielectric, ferroelectric and piezoelectric properties of La-substituted BiFeO3-BaTiO3 ceramics. Ceram Int, 2013, 39(4): 4307 doi: 10.1016/j.ceramint.2012.11.012

|

| [21] |

Guo Y Q, Wang T, He L H, et al. Enhanced ferroelectric and ferromagnetic properties of Er-modified BiFeO3-BaTiO3 lead-free multiferroic ceramics. J Mater Sci Mater Electron, 2016, 27(6): 5741 doi: 10.1007/s10854-016-4487-4

|

| [22] |

Wang J, Zhou C R, Li Q N, et al. Simultaneously enhanced piezoelectric properties and depolarization temperature in calcium doped BiFeO3-BaTiO3 ceramics. J Alloys Compd, 2018, 748: 758 doi: 10.1016/j.jallcom.2018.03.174

|

| [23] |

Zhou C R, Cen Z Y, Yang H B, et al. Structure, electrical properties of Bi(Fe, Co)O3-BaTiO3 piezoelectric ceramics with improved Curie temperature. Physica B, 2013, 410: 13 doi: 10.1016/j.physb.2012.11.003

|

| [24] |

Zheng T, Jiang Z G, Wu J G. Enhanced piezoelectricity in (1-x)Bi1.05Fe1-yAyO3-xBaTiO3 lead-free ceramics: site engineering and wide phase boundary region. Dalton Trans, 2016, 45: 11277 doi: 10.1039/C6DT01805J

|

| [25] |

Zhu L F, Zhang B P, Li S, et al. Enhanced piezoelectric properties of Bi(Mg1/2Ti1/2)O3 modified BiFeO3-BaTiO3 ceramics near the morphotropic phase boundary. J Alloys Compd, 2016, 664: 602 doi: 10.1016/j.jallcom.2016.01.003

|

| [26] |

Zhou C R, Feteira A, Shan X, et al. Remarkably high-temperature stable piezoelectric properties of Bi(Mg0.5Ti0.5)O3 modified BiFeO3-BaTiO3 ceramics. Appl Phys Lett, 2012, 101(3): 032901 doi: 10.1063/1.4736724

|

| [27] |

Zhou Q, Zhou C R, Yang H B, et al. Dielectric, ferroelectric, and piezoelectric properties of Bi(Ni1/2Ti1/2)O3-modified BiFeO3-BaTiO3 ceramics with high Curie temperature. J Am Ceram Soc, 2012, 95(12): 3889 doi: 10.1111/j.1551-2916.2012.05387.x

|

| [28] |

Shan X, Zhou C R, Cen Z Y, et al. Bi(Zn1/2Ti1/2)O3 modified BiFeO3-BaTiO3 lead-free piezoelectric ceramics with high temperature stability. Ceram Int, 2013, 39(6): 6707 doi: 10.1016/j.ceramint.2013.01.110

|

| [29] |

Zheng Q J, Guo Y Q, Lei F Y, et al. Microstructure, ferroelectric, piezoelectric and ferromagnetic properties of BiFeO3-BaTiO3-Bi(Zn0.5Ti0.5)O3 lead-free multiferroic ceramics. J Mater Sci Mater Electron, 2014, 25(6): 2638 doi: 10.1007/s10854-014-1923-1

|

| [30] |

Chen J Y, Zhang B P, Zhu L F, et al. Enhanced insulation resistance and electrical properties of BiFe1-x(Zn0.5Ti0.5)xO3-BaTiO3 lead-free piezoceramics. Ceram Int, 2018, 44(7): 8409 doi: 10.1016/j.ceramint.2018.02.034

|

| [31] |

Zhu L F, Zhang B P, Duan J Q, et al. Enhanced piezoelectric and ferroelectric properties of BiFeO3-BaTiO3 lead-free ceramics by optimizing the sintering temperature and dwell time. J Eur Ceram Soc, 2018, 38(10): 3463 doi: 10.1016/j.jeurceramsoc.2018.03.044

|

| [32] |

Qin Y F, Yang J, Xiong P, et al. The effects of quenching on electrical properties, and leakage behaviors of 0.67BiFeO3-0.33BaTiO3 solid solutions. J Mater Sci Mater Electron, 2018, 29(9): 7311 doi: 10.1007/s10854-018-8720-1

|

| [33] |

Sosnowska I, Zvezdin A K. Origin of the long period magnetic ordering in BiFeO3. J Magn Magn Mater, 1995, 140-144: 167 doi: 10.1016/0304-8853(94)01120-6

|

| [34] |

Gippius A A, Khozeev D F, Morozova E N, et al. Observation of spin modulated magnetic structure at Bi-and Fe-sites in BiFeO3 by nuclear magnetic resonance. Phys Status Solidi A, 2003, 196(1): 221 doi: 10.1002/pssa.200306391

|

| [35] |

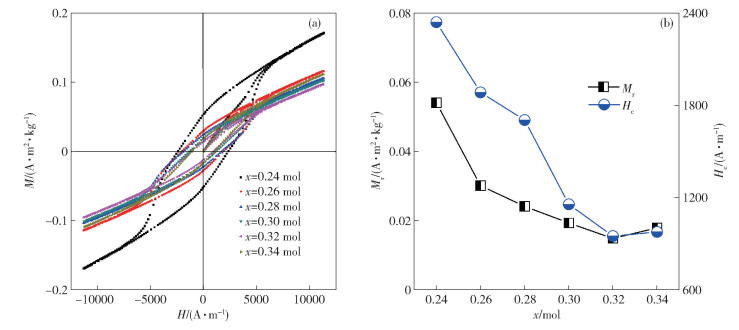

Zhu L F, Zhang B P, Zhang Z C, et al. Piezoelectric, ferroelectric and ferromagnetic properties of (1-x)BiFeO3-xBaTiO3 lead-free ceramics near morphotropic phase boundary. J Mater Sci Mater Electron, 2018, 29(3): 2307 doi: 10.1007/s10854-017-8147-0

|

| [36] |

Dai Z H, Liu L, Ying G B, et al. Structural, dielectric and magnetic properties of Mn modified xBiFeO3-(1-x)BaTiO3 ceramics. J Magn Magn Mater, 2017, 434: 10 doi: 10.1016/j.jmmm.2016.10.131

|

| [37] |

Liu X H, Xu Z, Qu S B, et al. Ferroelectric and ferromagnetic properties of Mn-doped 0.7BiFeO3-0.3BaTiO3 solid solution. Ceram Int, 2008, 34(4): 797 doi: 10.1016/j.ceramint.2007.09.029

|

下載:

下載: