Ultrasonic refining mechanism of ternary phase in Al–Sc based alloys prepared through molten salt electrolysis

-

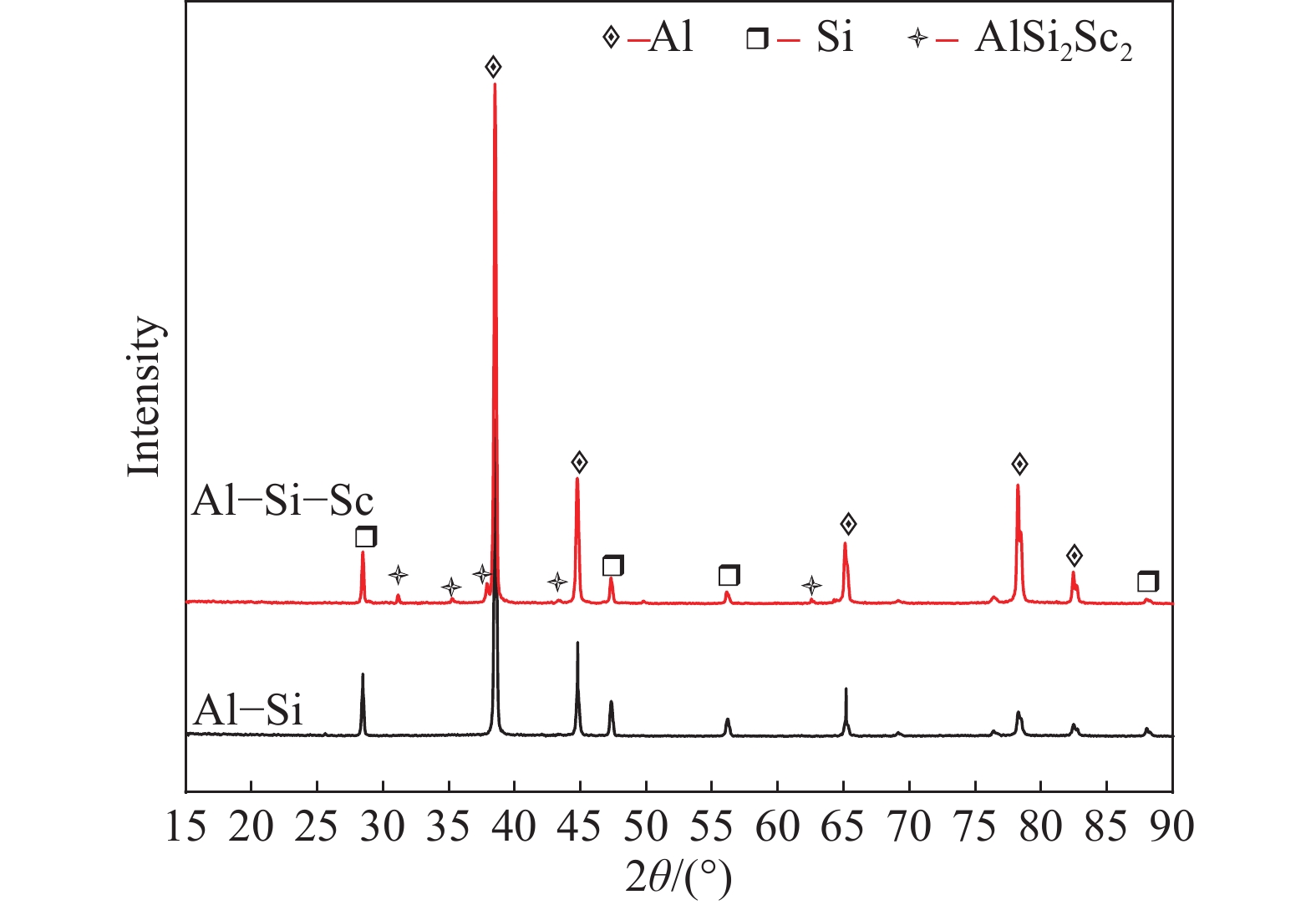

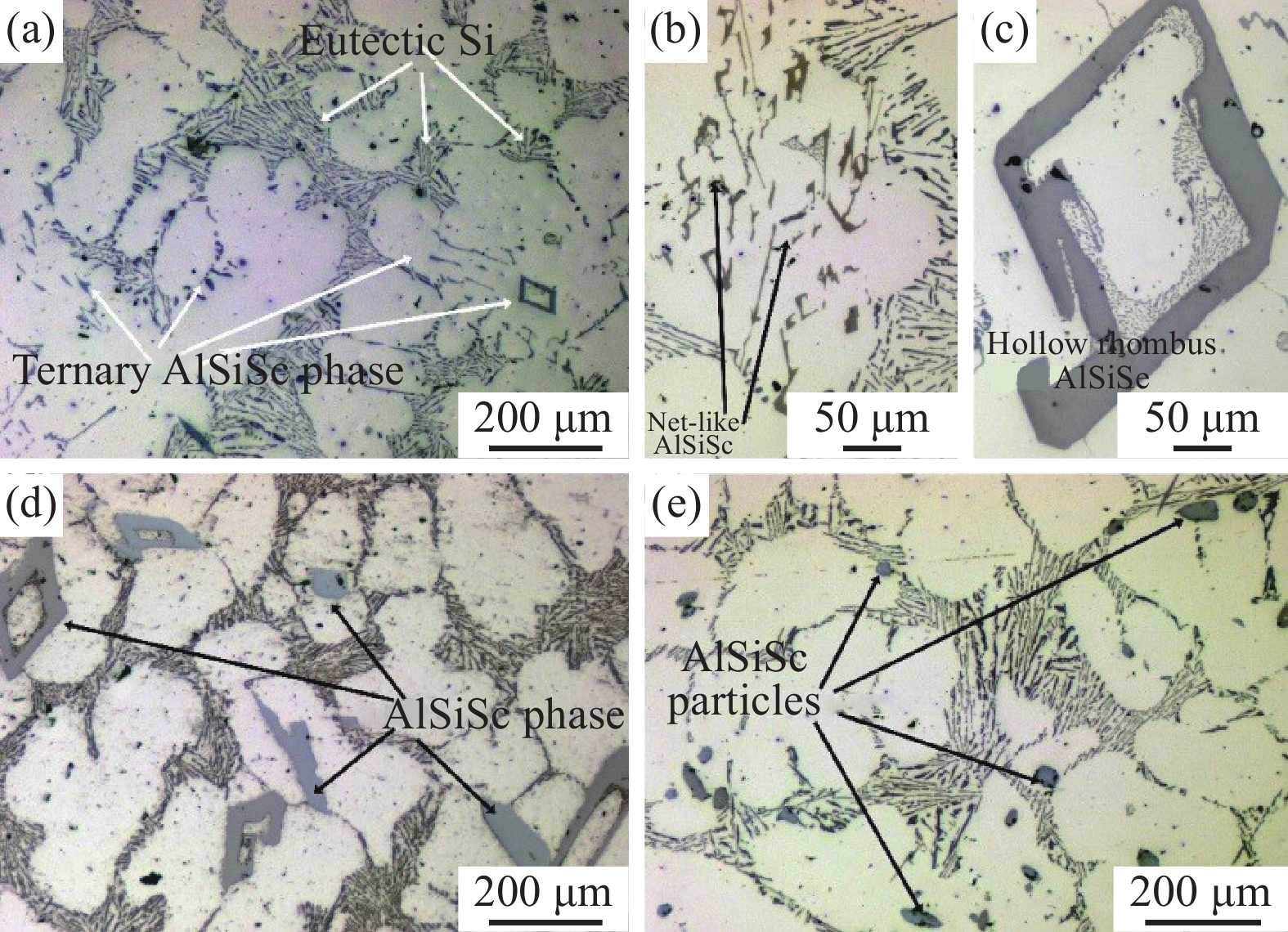

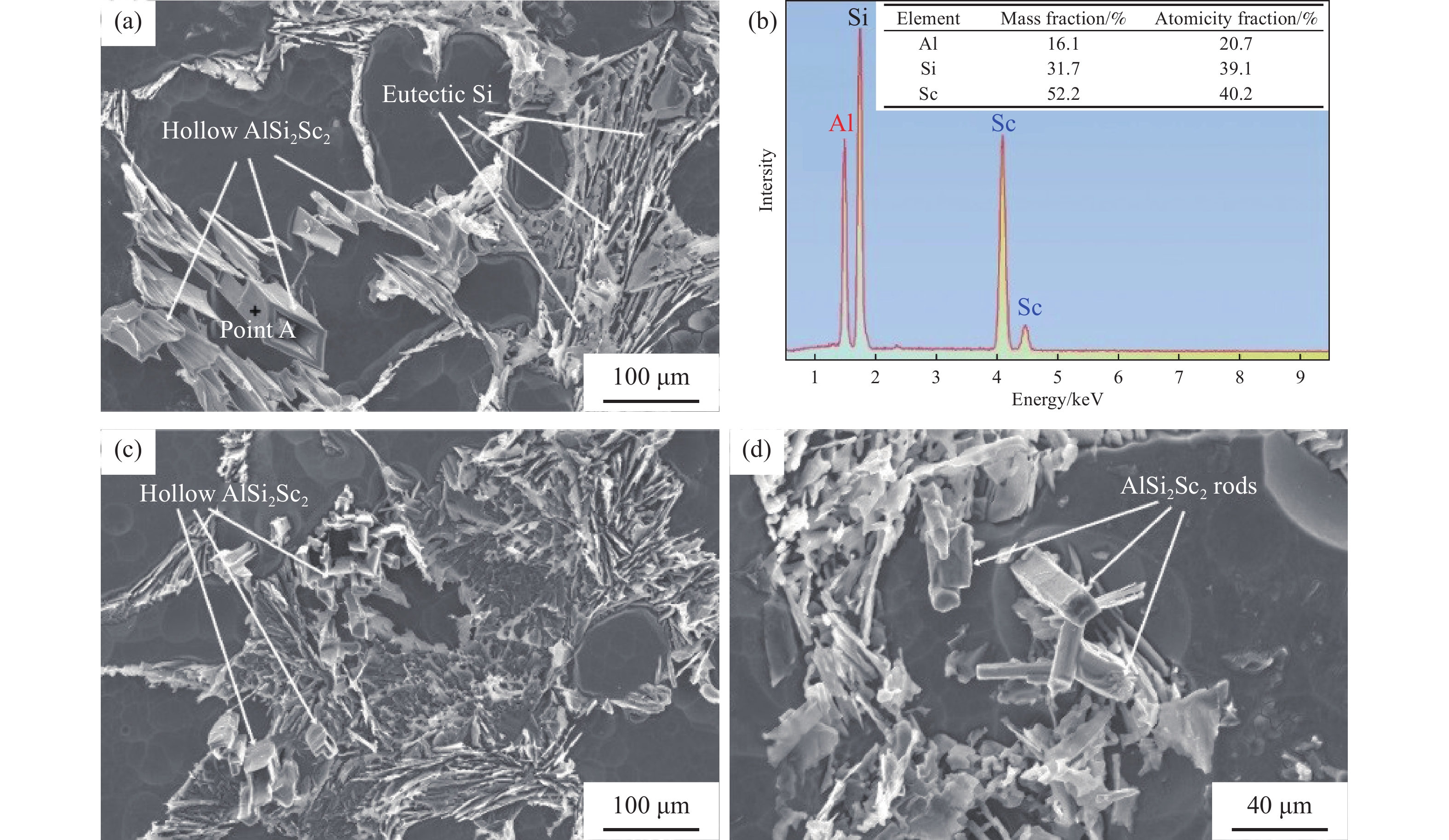

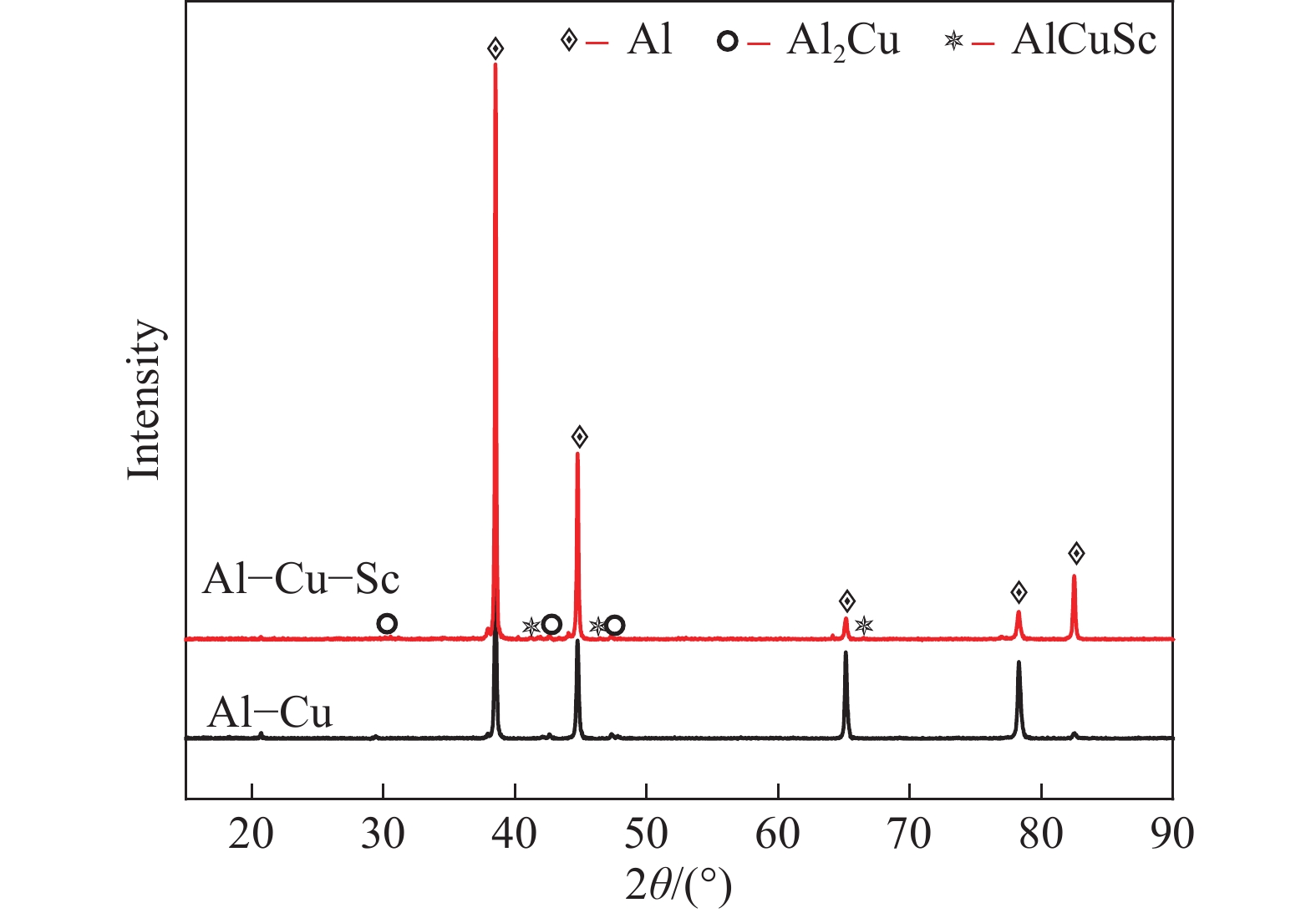

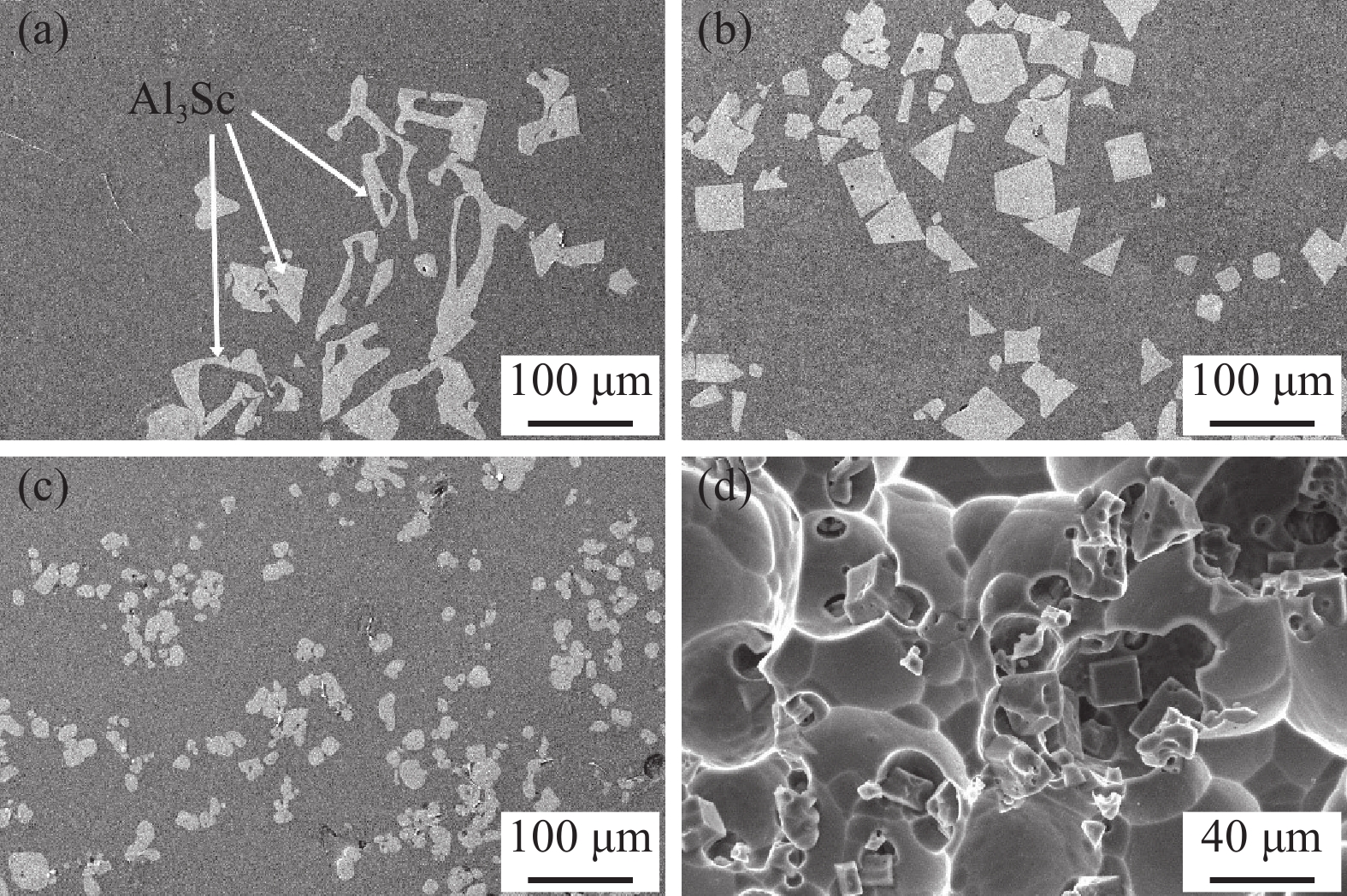

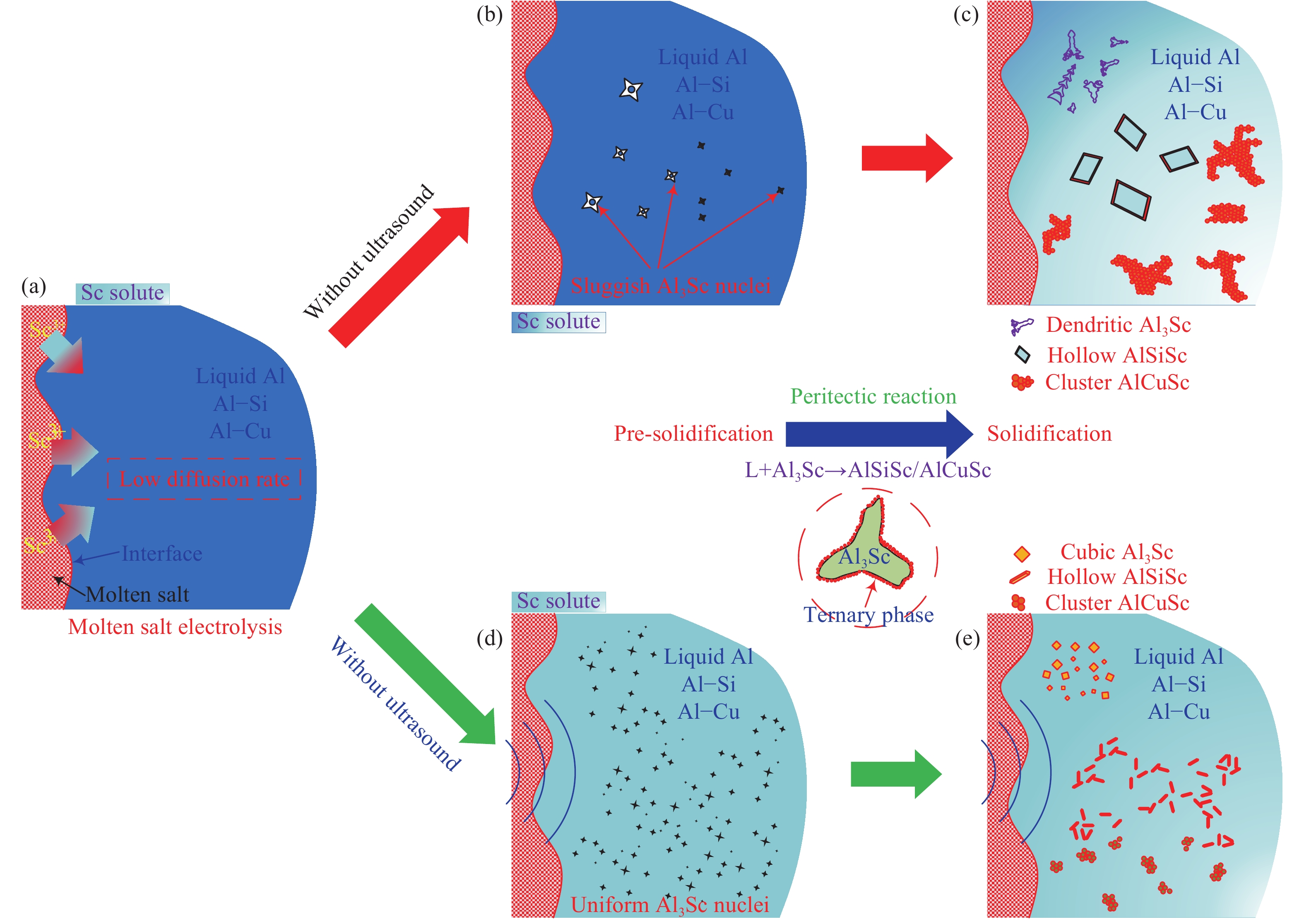

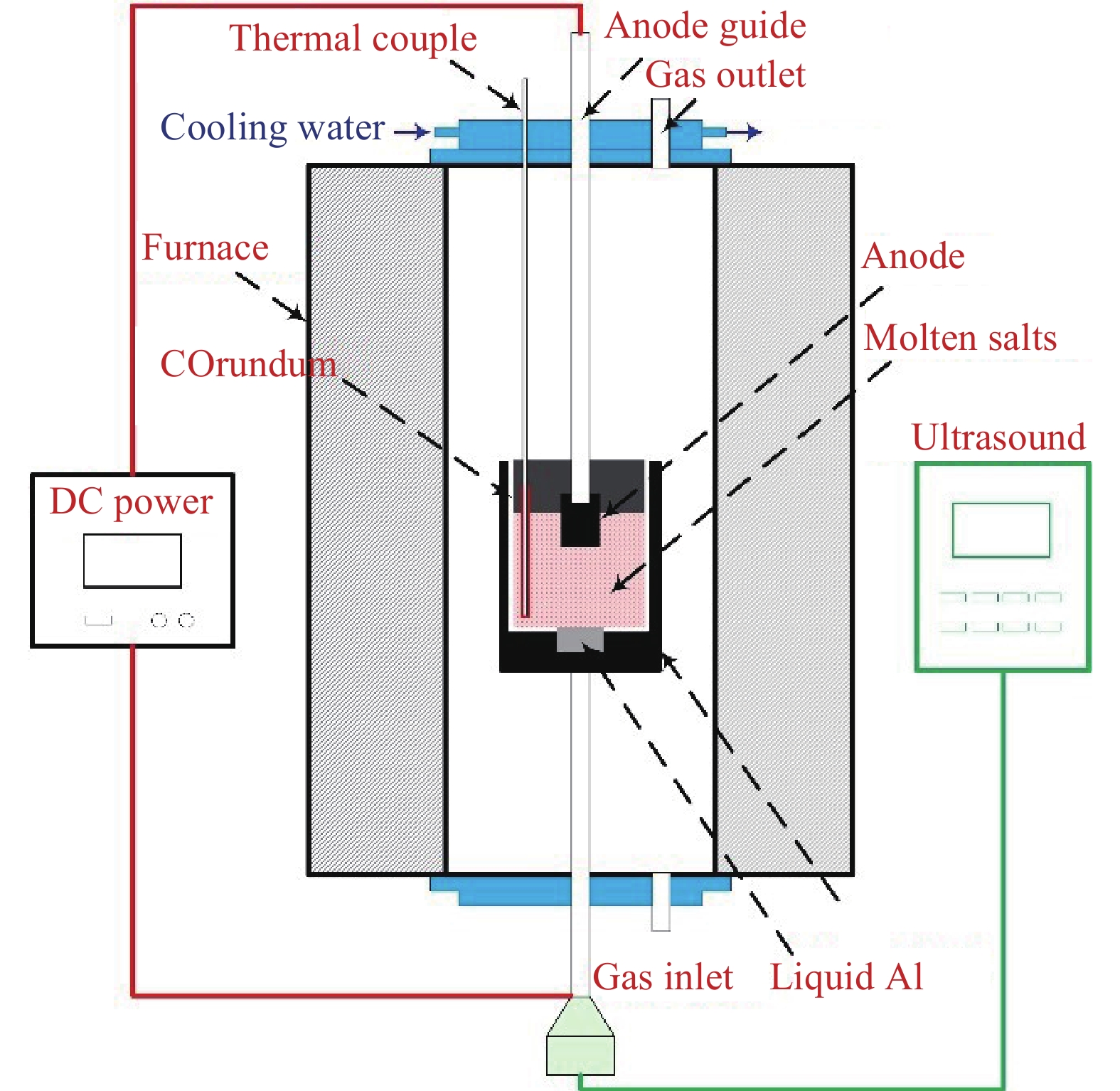

摘要: 研究采用超聲協同熔鹽電解法制備Al–Si–Sc和Al–Cu–Sc合金,采用光學顯微鏡、掃描電鏡和X射線衍射研究超聲對合金中三元含鈧強化相形貌與尺寸的影響,進而闡明超聲細化機制。研究結果表明,協同超聲促使三元AlSiSc相由粗大菱形管狀轉變為細小實心方棒狀,其尺寸由205減小到40 μm左右;超聲顯著細化三元AlCuSc相團簇尺寸,由約100減小至約30 μm;超聲協同細化機制主要是通過提高形核率細化初生Al3Sc相并促進其均勻分布,進而作為形核發育基底,最終實現三元含鈧相細化;同時超聲也可促進合金溶質均勻分布,避免粗大Al3Sc相析出;超聲細化三元含鈧相機制主要作用于電解后凝固階段。Abstract: Aluminum alloys are widely used in cutting-edge technologies and emerging strategic industries, namely aerospace, high-speed rail transportation, electric vehicles, advanced functional materials, new energy storage, and conversion devices. The processability as well as the mechanical properties of aluminum alloys can be improved via the addition of trace scandium. The ultrasonically assisted molten salt electrolysis is a promising, short technical route for large-scale preparation of low-cost, Al–Sc-based alloys characterized by uniform and fine strengthening phases. At present, it is still unclear if that is the case for the ultrasonic refining mechanism of the Sc-bearing ternary phase. This study aims at clarifying the ultrasonic refining mechanism on the strengthening phase containing scandium. Two Al–Sc based alloys were prepared using ultrasonically assisted molten salt electrolysis while the effect of ultrasound on the morphology and size of the Sc-bearing ternary phase was studied using optical microscope, scanning electron microscope, and X-ray diffraction meter. The results show that the synergetic ultrasound facilitates the transformation of the ternary AlSiSc phase from the coarse rhombic tubes (~205 μm) to the short rod (40 μm). The cluster size of ternary AlCuSc phase is also greatly reduced from ~100 μm to ~30 μm. The ultrasonic refining mechanism is mainly related to the increase of the nucleation rate of the primary Al3Sc particles which are greatly refined and dispersed in the alloy melt before the solidification stage. The refinement of the Sc-bearing ternary phase is considered to be caused by the fine and disperse Al3Sc particles serving as nuclei. Furthermore, ultrasound can also aid the uniform distribution of solute field and prevent the precipitation of coarse Al3Sc phase. The effect of ultrasonic refinement of the ternary rhenium-containing phase is mainly present at the solidification stage after electrolysis.

-

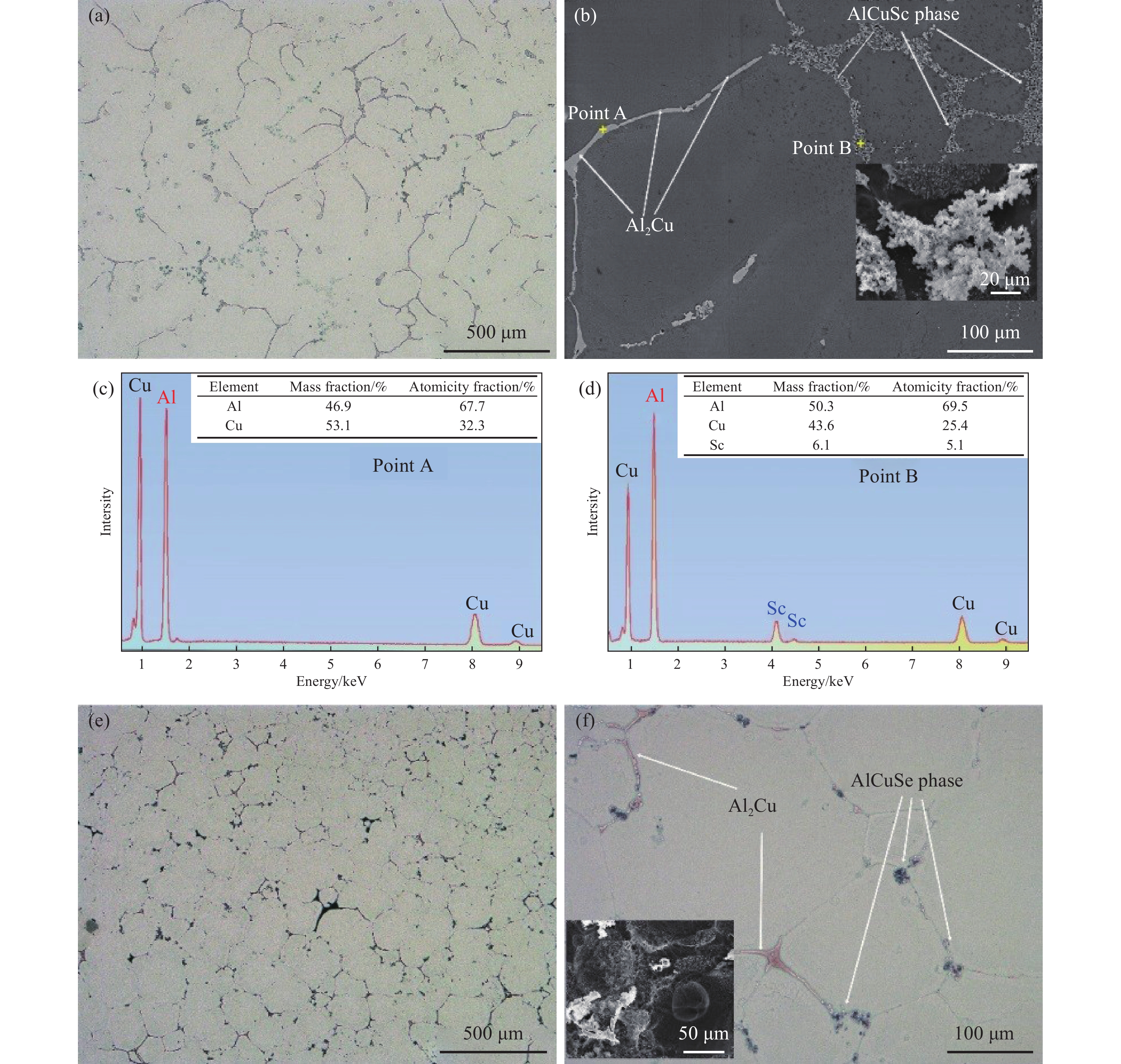

圖 6 熔鹽電解Al–Cu–Sc合金微觀組織。(a)常規電解合金金相照片;(b)常規電解合金掃描電鏡形貌(插圖為深腐蝕后AlCuSc相);(c~d)圖6(b)中點A和B的能譜圖;(e~f)超聲協同電解–凝固合金金相照片(插圖為深腐蝕后AlCuSc相掃描電鏡形貌)

Figure 6. Microstructures of the Al–Cu–Sc alloys prepared by molten salt electrolysis: (a) MSE (OM); (b) MSE (SEM, inserted figure showing the AlCuSc after deep etching); (c–d) EDS analysis of point A and B, respectively in Fig.6(b); (e–f) US-MSE/US-SOL (OM, inserted SEM figure showing the AlCuSc after deep etching)

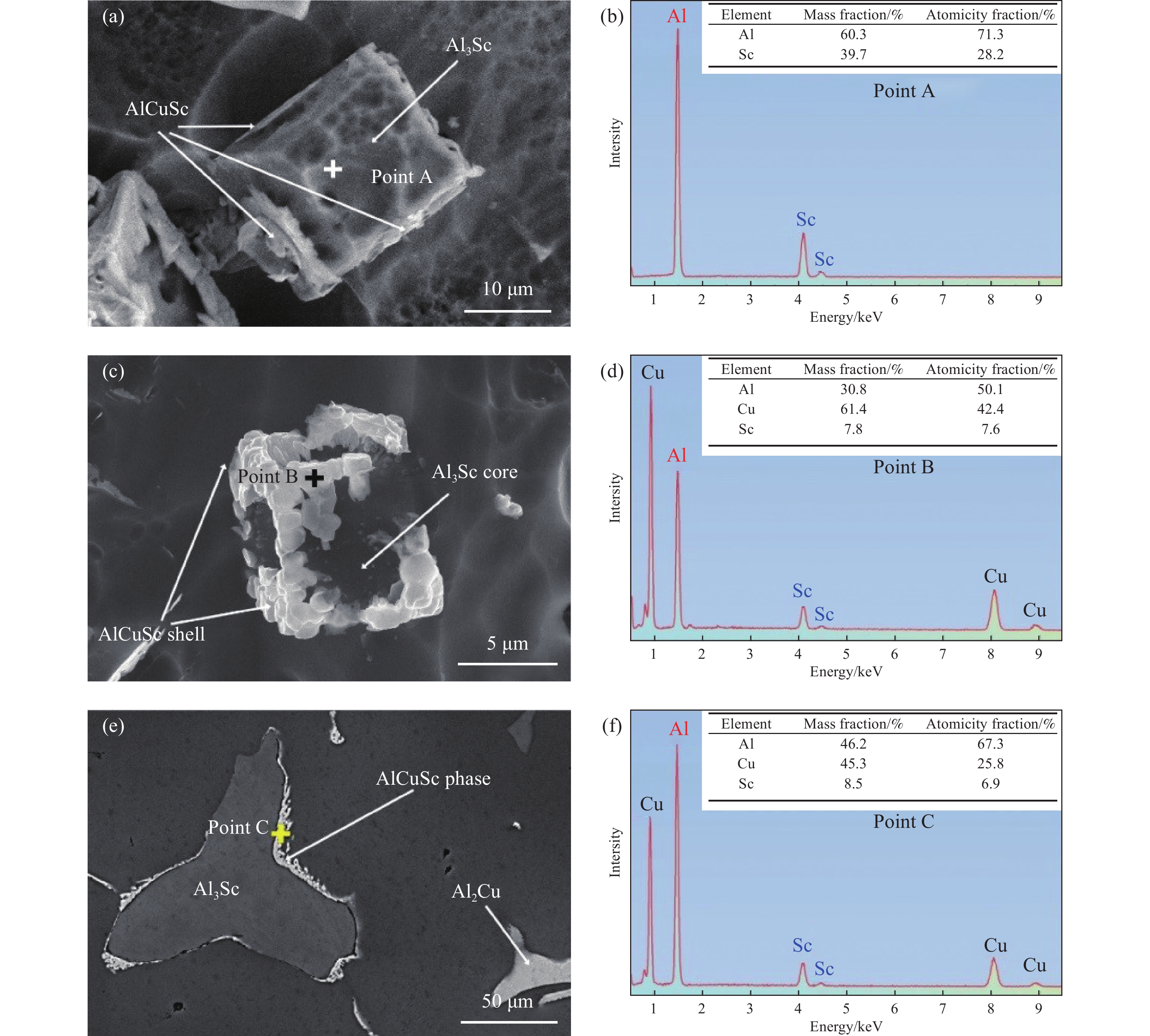

圖 7 超聲協同熔鹽電解Al–Cu–Sc合金中三元AlCuSc相掃描電鏡形貌。(a) Al3Sc核心;(b)點A能譜圖分析;(c) AlCuSc外殼;(d)點B能譜圖分析;(e)包覆Al3Sc的AlCuSc相;(f)點C能譜圖分析

Figure 7. SEM micrographs of the AlCuSc ternary phase in Al–Cu–Sc alloy, prepared by ultrasound-assisted molten salt electrolysis: (a) Al3Sc nuclei; (b) EDS analysis of point A; (c) AlCuSc shell; (d) EDS analysis of point B; (e) Al3Sc covered by AlCuSc phase; (f) EDS analysis of point A

中文字幕在线观看表 1 合金含鈧相尺寸量化結果

Table 1. Particle size of the Sc-containing phase in the investigated alloys

Alloy Particle size /μm MSE US-MSE US-MSE/US-SOL Al–Sc 96±34 48±12 22±7 Al–Si–Sc 205±82 228±96 40±10 Al–Cu–Sc 94±36 — 30±5 -

參考文獻

[1] Tian S K, Li J Y, Zhang J L, et al. Effect of Sc on the microstructure and properties of 7056 aluminum alloy. Chin J Eng, 2019, 41(10): 1298田少鯤, 李靜媛, 張俊龍, 等. Sc對7056鋁合金組織和性能的影響. 工程科學學報, 2019, 41(10):1298 [2] Qian Y, Xue J L, Wang Z J, et al. Mechanical properties evaluation of Zr addition in L12-Al3(Sc1–xZrx) using first-principles calculation. JOM, 2016, 68(5): 1293 doi: 10.1007/s11837-016-1880-7 [3] Riva S, Yusenko K V, Lavery N P, et al. The scandium effect in multicomponent alloys. Int Mater Rev, 2016, 61(3): 203 doi: 10.1080/09506608.2015.1137692 [4] Czerwinski F. Critical assessment 36: assessing differences between the use of cerium and scandium in aluminium alloying. Mater Sci Technol, 2020, 36(3): 255 doi: 10.1080/02670836.2019.1702775 [5] Royset J, Ryum N. Scandium in aluminium alloys. Int Mater Rev, 2005, 50(1): 19 doi: 10.1179/174328005X14311 [6] Li L X, Wang T S, Huang X L, et al. Research progress on the preparation of Al–Sc master alloy by molten salt electrolysis method. Mater Rev, 2018, 32(21): 3768 doi: 10.11896/j.issn.1005-023X.2018.21.013李亮星, 王濤勝, 黃茜琳, 等. 熔鹽電解法制備鋁鈧中間合金研究進展. 材料導報, 2018, 32(21):3768 doi: 10.11896/j.issn.1005-023X.2018.21.013 [7] Zhang C, Xue J L, Liu X, et al. Production of aluminum alloys in electrolysis cells based on Hall-Héroult process: a review. Chin J Eng, 2019, 41(7): 835張城, 薛濟來, 劉軒, 等. 基于霍爾—埃魯特電解法制備鋁合金技術研究進展. 工程科學學報, 2019, 41(7):835 [8] Guo R, Cao W L, Zhai X J, et al. Preparation of Al–Sc application alloys by molten salt electrolysis method. Chin J Rare Met, 2008, 32(5): 645 doi: 10.3969/j.issn.0258-7076.2008.05.021郭瑞, 曹文亮, 翟秀靜, 等. 熔鹽電解法制備Al–Sc應用合金的工藝研究. 稀有金屬, 2008, 32(5):645 doi: 10.3969/j.issn.0258-7076.2008.05.021 [9] Harata M, Nakamura T, Yakushiji H, et al. Production of scandium and Al–Sc alloy by metallothermic reduction. Miner Process Extract Metall IMM Trans Sect C, 2008, 117(2): 95 [10] Liu Q C, Xue J L, Zhu J, et al. Processing Al–Sc alloys at liquid aluminum cathode in KF-AlF3 molten salt. ECS Trans, 2013, 50(11): 483 doi: 10.1149/05011.0483ecst [11] Shtefanyuk Y, Mann V, Pingin V, et al. Production of Al–Sc alloy by electrolysis of cryolite-scandium oxide melts // Light Metals 2015. New Jersey: John Wiley & Sons, Inc., 2015: 589 [12] Tian Z L, Lai Y Q, Zhang K, et al. Preliminary study on preparation of Al–Sc master alloy in Na3AlF6–K3AlF6–AlF3 melt // 7th International Symposium on High-Temperature Metallurgical Processing. New Jersey: John Wiley & Sons, Inc., 2016: 157 [13] Wang Z J, Guan C Y, Liu Q C, et al. Formation of intermetallic phases in Al–Sc alloys prepared by molten salt electrolysis at elevated temperatures // 6th International Symposium on High-Temperature Metallurgical Processing. New Jersey: John Wiley & Sons, Inc., 2015: 215 [14] Liu X, Xue J L, Guo Z C, et al. Segregation behaviors of Sc and unique primary Al3Sc in Al–Sc alloys prepared by molten salt electrolysis. J Mater Sci Technol, 2019, 35(7): 1422 doi: 10.1016/j.jmst.2019.02.002 [15] Liu X, Guo Z C, Xue J L, et al. Effects of synergetic ultrasound on the Sc yield and primary Al3Sc in the Al–Sc alloy prepared by the molten salts electrolysis. Ultrason Sonochem, 2019, 52: 33 doi: 10.1016/j.ultsonch.2018.09.009 [16] Guo Z C, Liu X, Xue J L. Fabrication of Al-Si-Sc alloy bearing AlSi2Sc2 phase using ultrasonically assisted molten salt electrolysis. J Alloys Compd, 2019, 797: 883 doi: 10.1016/j.jallcom.2019.05.133 [17] Guo Z C, Liu X, Xue J L, et al. Effects of ultrasound on the microstructure of Al–7Si–Sc alloy prepared via molten salt electrolysis. Chin J Eng, 2019, 41(9): 1135郭志超, 劉軒, 薛濟來, 等. 超聲對熔鹽電解法制備Al–7Si–Sc合金組織的影響. 工程科學學報, 2019, 41(9):1135 [18] Liu X, Guo Z C, Xue J L, et al. Microstructures and mechanical properties of the Al–Cu–Sc alloys prepared by ultrasound-assisted molten salt electrolysis. J Alloys Compd, 2020, 818: 152870 doi: 10.1016/j.jallcom.2019.152870 [19] Raghavan V. Phase diagram updates and evaluations of the Al–Fe–Ta, Al–Ge–Ni, Al–Li–Zn, Al–Sc–Si and Al–Ta–Ti systems. J Phase Equilib Diff, 2013, 34(4): 328 doi: 10.1007/s11669-013-0239-9 [20] Pandee P, Gourlay C M, Belyakov S A, et al. AlSi2Sc2 intermetallic formation in Al–7Si–0.3Mg–xSc alloys and their effects on as-cast properties. J Alloys Compd, 2018, 731: 1159 doi: 10.1016/j.jallcom.2017.10.125 [21] Bo H, Liu L B, Jin Z P. Thermodynamic analysis of Al–Sc, Cu–Sc and Al–Cu–Sc system. J Alloys Compd, 2010, 490(1-2): 318 doi: 10.1016/j.jallcom.2009.10.003 [22] Raghavan V. Al–Cu–Sc (Aluminum-Copper-Scandium). J Phase Equilib Diff, 2010, 31(6): 554 doi: 10.1007/s11669-010-9771-z [23] Dai Y N. Binary Alloys Phase Diagrams. Beijing: Science Press, 2009戴永年. 二元合金相圖集. 北京: 科學出版社, 2009 [24] Liu X, Zhang C, Zhang Z Q, et al. The role of ultrasound in hydrogen removal and microstructure refinement by ultrasonic argon degassing process. Ultrason Sonochem, 2017, 38: 455 doi: 10.1016/j.ultsonch.2017.03.041 [25] Liu X, Xue J L, Zhao Q, et al. Effects of radiator shapes on the bubble diving and dispersion of ultrasonic argon process. Ultrason Sonochem, 2018, 41: 600 doi: 10.1016/j.ultsonch.2017.10.026 [26] Xu T, Zhang L H, Li R Q, et al. Numerical simulation and experimental study of multi-field coupling for semi-continuous casting of large-scale aluminum ingots with ultrasonic treatment. Chin J Eng, 2016, 38(9): 1270徐婷, 張立華, 李瑞卿, 等. 鋁合金大鑄錠超聲半連鑄多場耦合的數值模擬與實驗研究. 工程科學學報, 2016, 38(9):1270 [27] Shang B, Jiang R P, Li X Q, et al. Effect of ultrasonic outfield on solidification rules of ZL205A aluminum alloy under different temperature-control states. Chin J Eng, 2019, 41(8): 1007商兵, 蔣日鵬, 李曉謙, 等. 超聲外場對不同溫控狀態下ZL205A鋁合金凝固規律的影響. 工程科學學報, 2019, 41(8):1007 [28] Zhong Z T, Li R Q, Li X Q, et al. Effect of ultrasonication on the microstructure and macrosegregation of a large 2219 aluminum ingot. Chin J Eng, 2017, 39(9): 1347鐘貞濤, 李瑞卿, 李曉謙, 等. 超聲處理對2219大規格鋁錠微觀組織與宏觀偏析的影響. 工程科學學報, 2017, 39(9):1347 [29] Liu X, Zhang J F, Li H Y, et al. Electrical resistivity behaviors of liquid Pb–Sn binary alloy in the presence of ultrasonic field. Ultrasonics, 2015, 55: 6 doi: 10.1016/j.ultras.2014.07.008 -

下載:

下載: