-

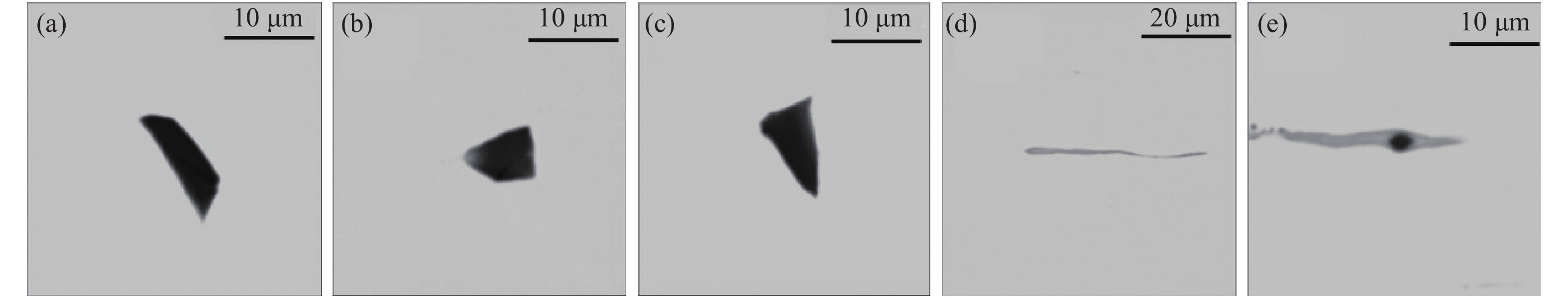

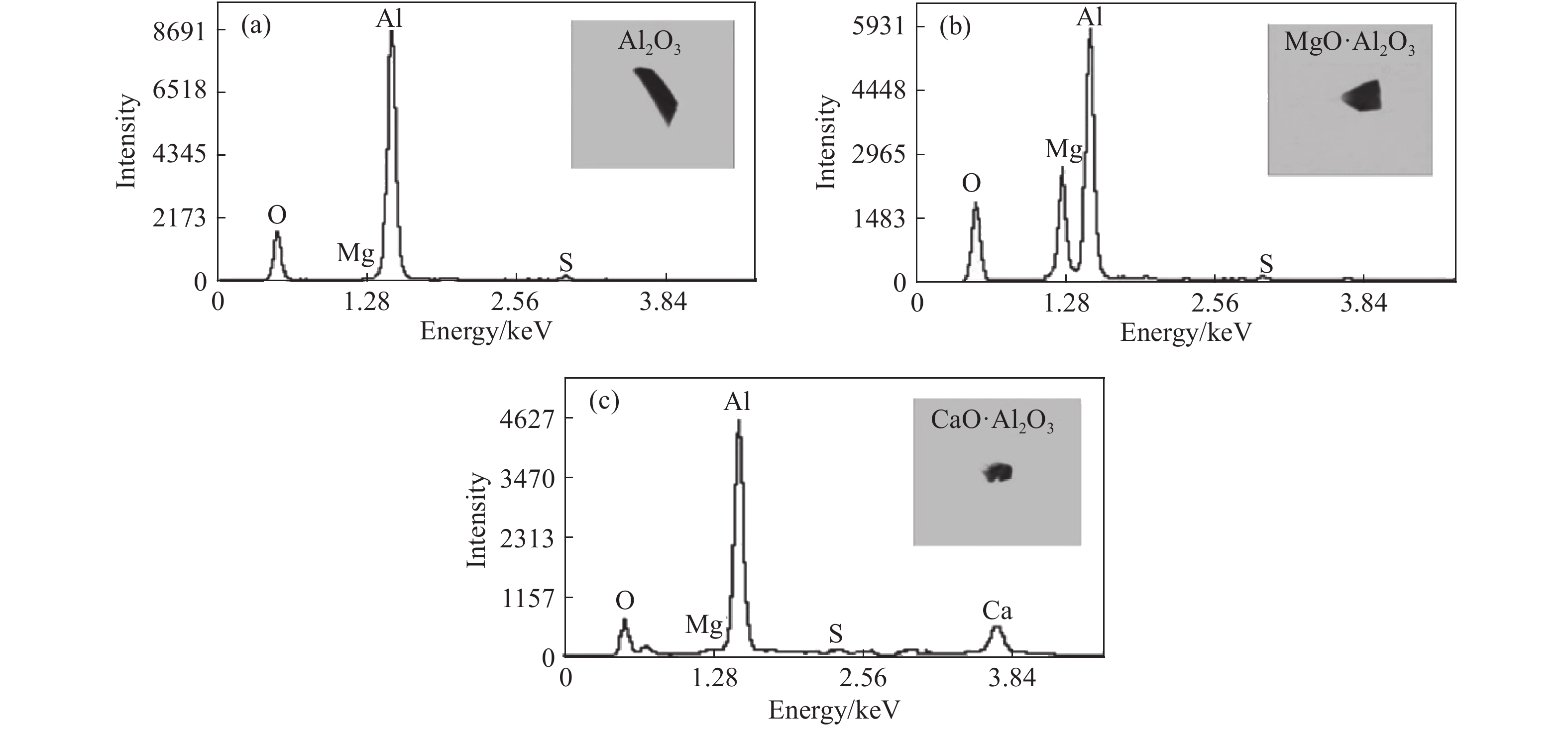

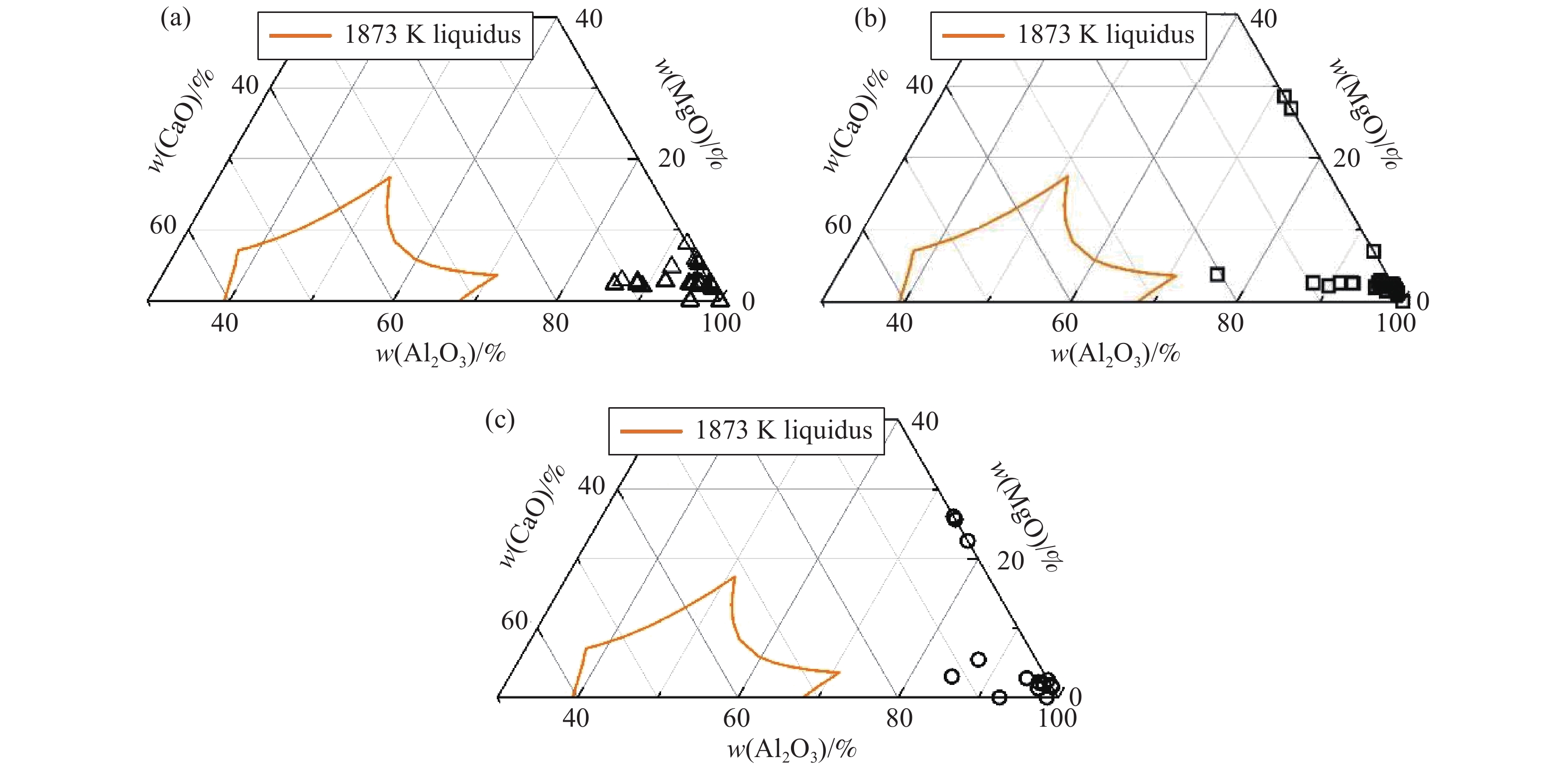

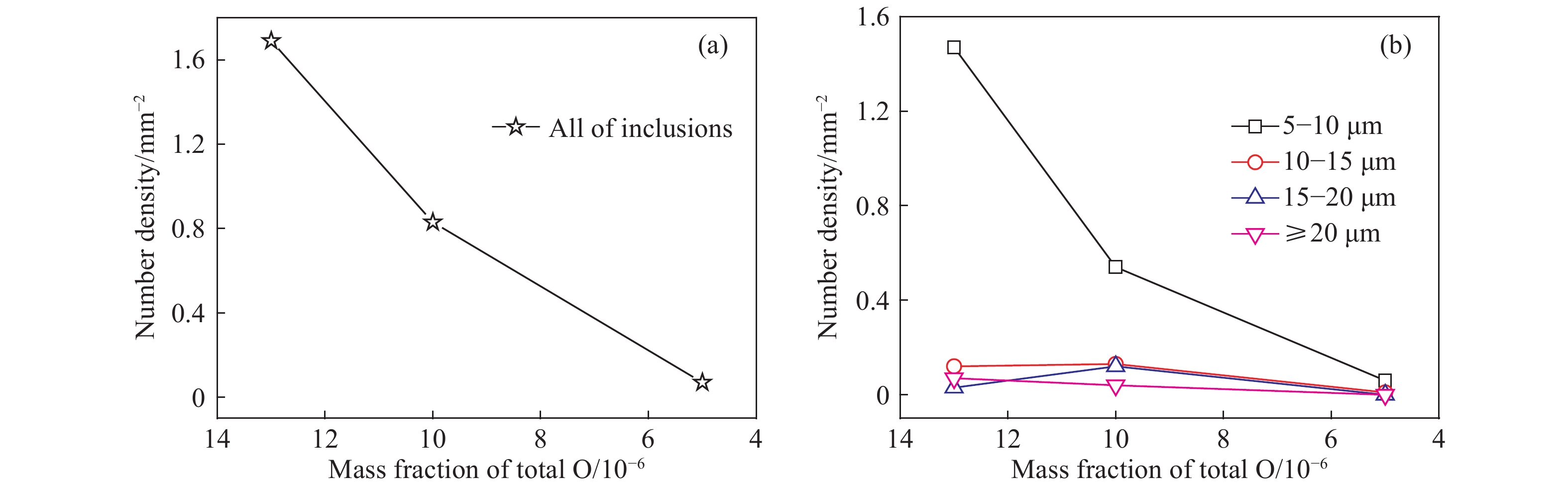

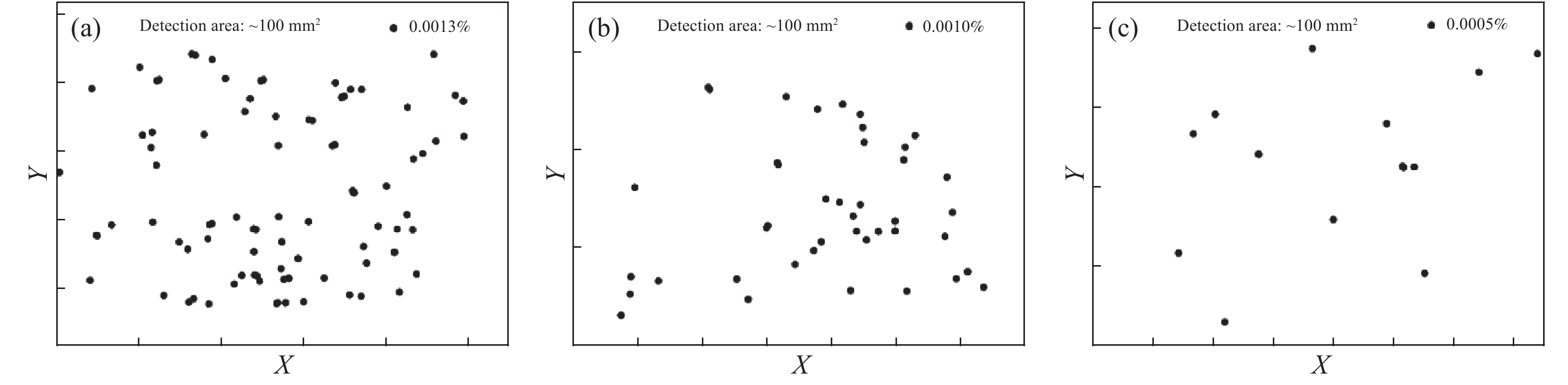

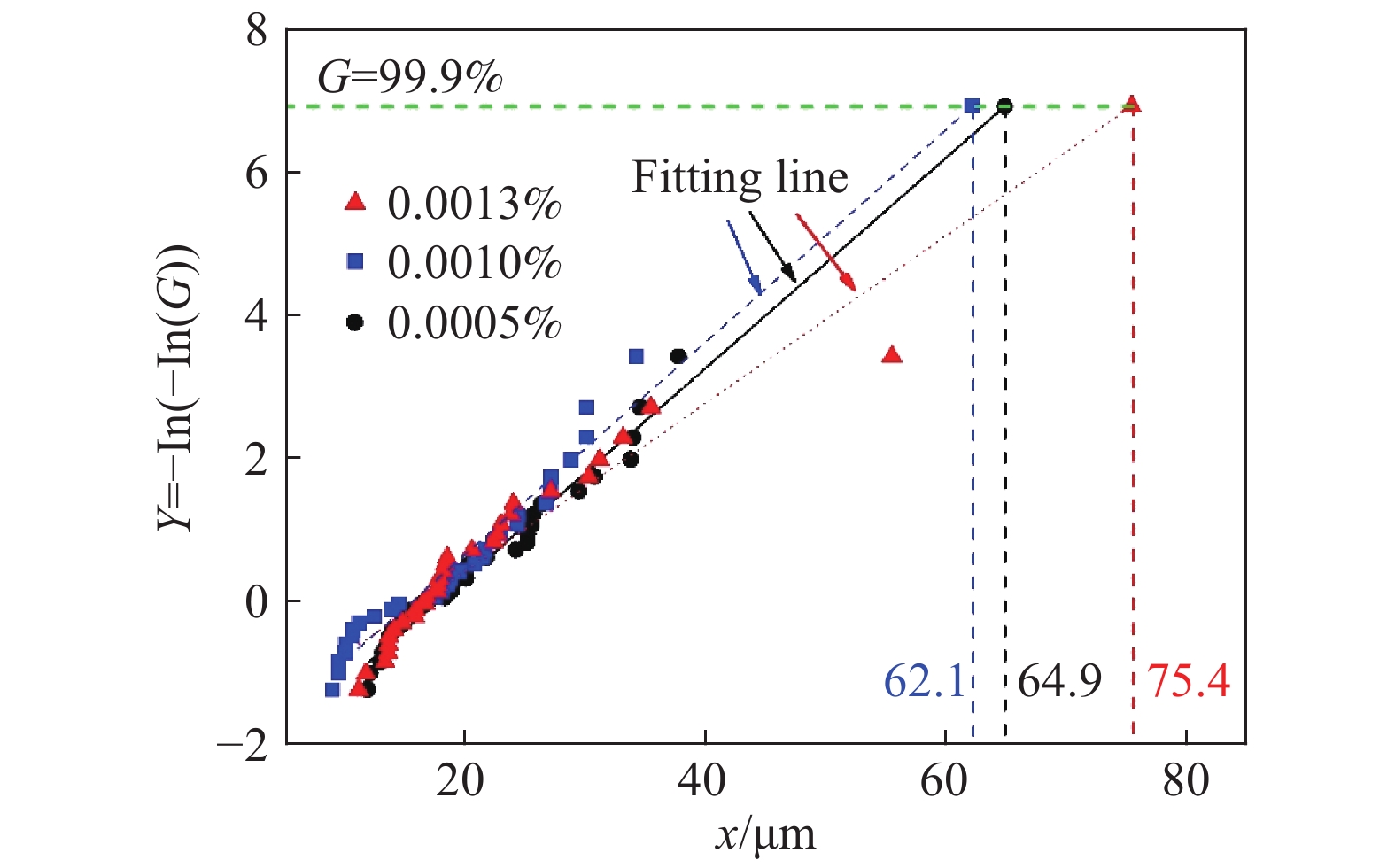

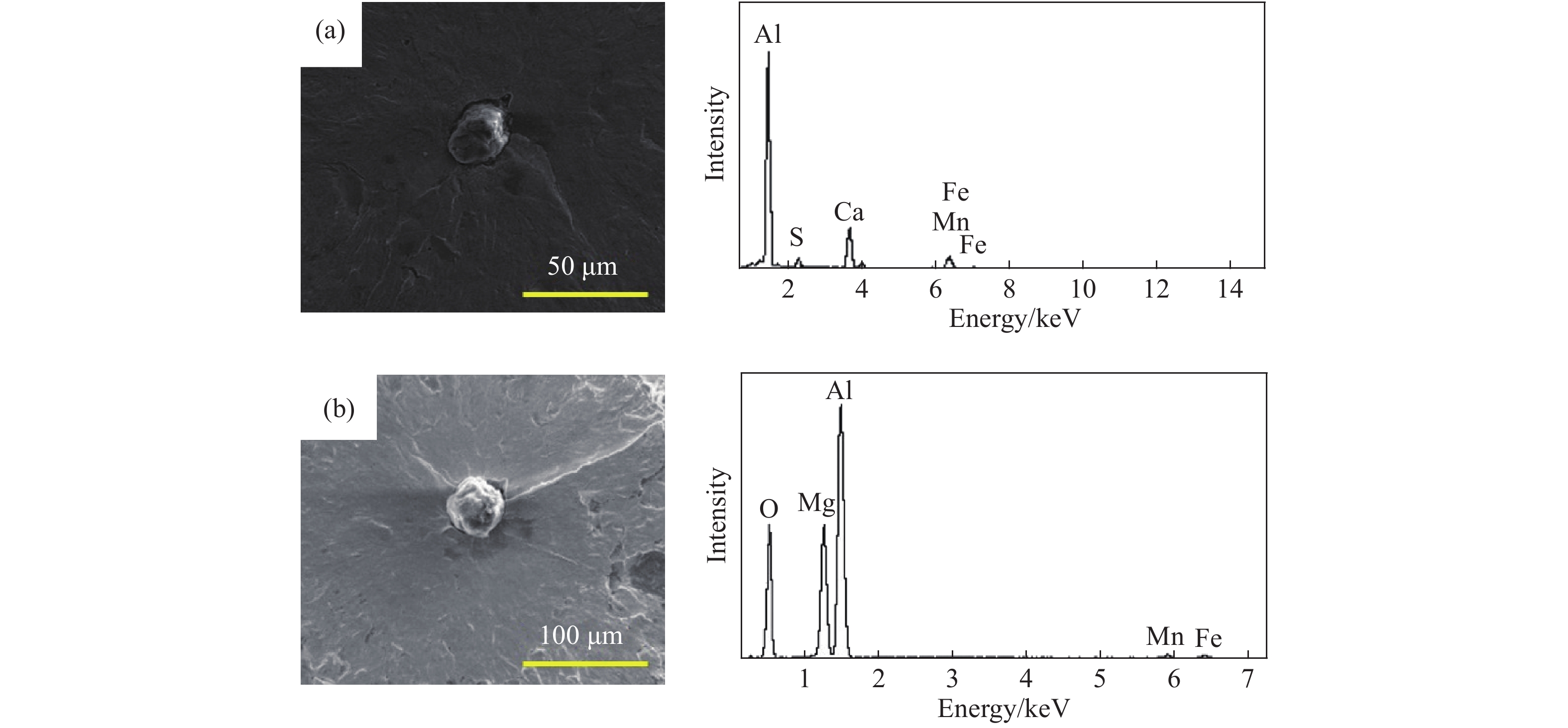

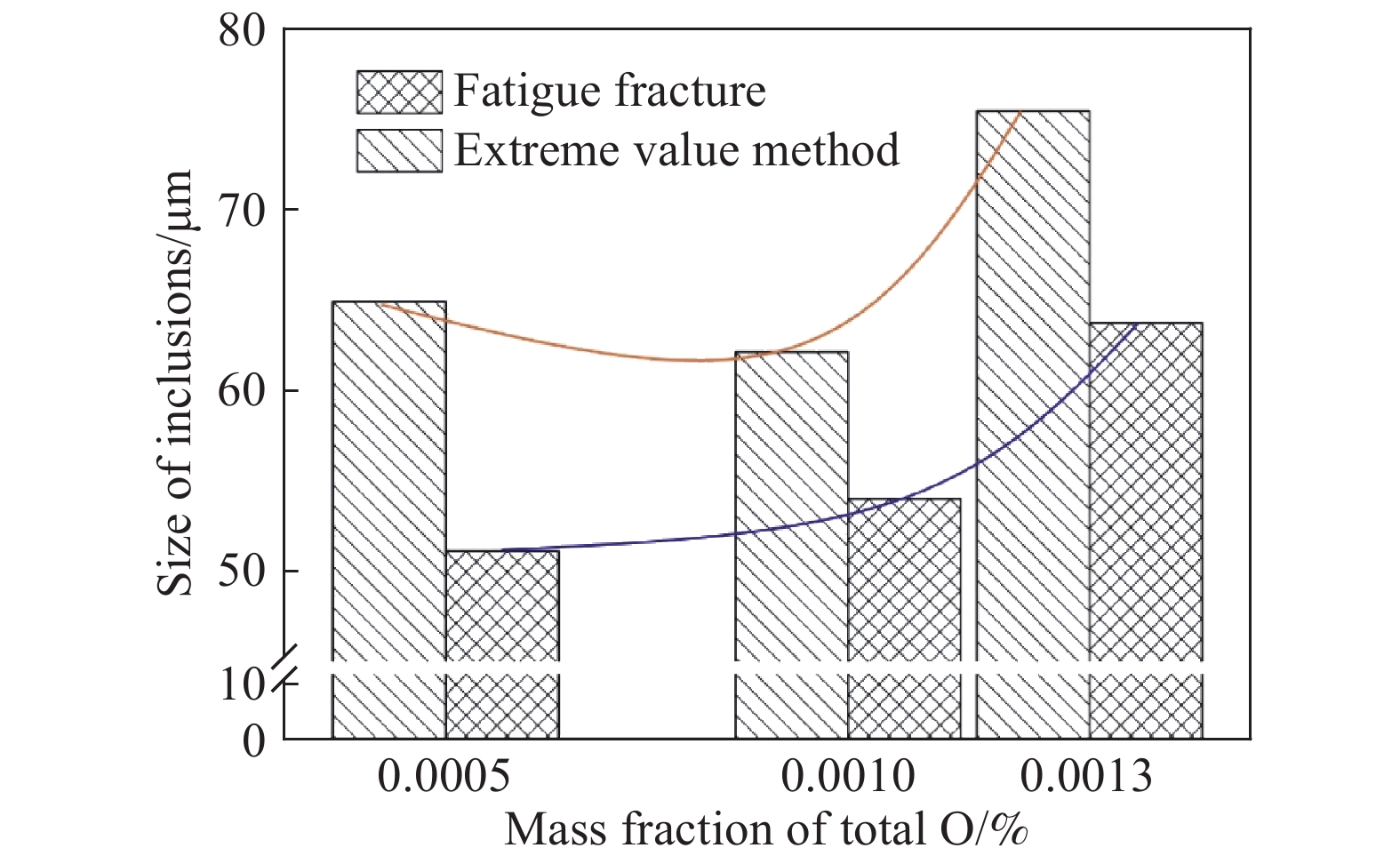

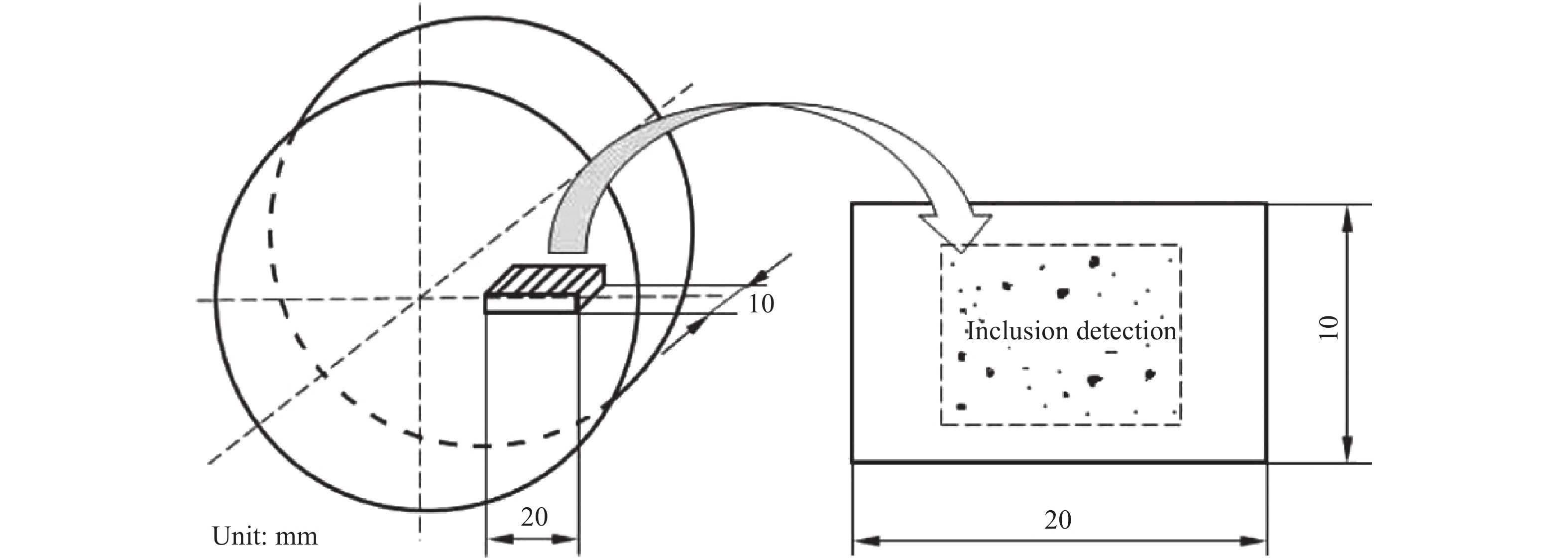

摘要: 為了保證齒輪鋼中非金屬夾雜物的控制,并確定齒輪鋼經濟合理的總氧含量控制目標,開展了總氧含量對齒輪鋼中非金屬夾雜物的影響研究。以三種不同總氧含量的Mn–Cr系齒輪鋼為研究對象,利用Aspex掃描電鏡、極值法、疲勞測試等不同方法研究了齒輪鋼中非金屬夾雜物數量、分布、尺寸等,獲得了夾雜物與齒輪鋼總氧含量的對應關系。在本文實驗條件下,隨著總氧含量的降低,鋼中氧化物夾雜數量不斷減小,其中5~10 μm的小尺寸夾雜物減小最明顯,而10 μm以上的大尺寸夾雜物數量變化規律不明顯。另外,極值法和疲勞試驗結果表明,總氧含量高時(質量分數為0.0013%),鋼中最大氧化物夾雜尺寸也較大,比總氧質量分數為0.0010%和0.0005%的實驗鋼的最大夾雜物尺寸高10 μm以上,且當總氧含量比較低時(質量分數≤0.0010%),實驗鋼總氧質量分數變化(0.0010%、0.0005%)對鋼中最大夾雜物尺寸影響不大。Abstract: It is an important symbol of the metallurgical quality level of special steel for inclusion controlling, which can improve the service performance of special steel to a greater extent. As a typical steel grade, gear steel, in the special steel field, is also required strictly in controlling of inclusions. It is known that total oxygen content can reflect the level of inclusions to some extent. Since the 1980s, ultralow oxygen has become a direction for the development of special steel. To guarantee controlling of nonmetallic inclusions and determine a reasonable control target of total oxygen content in the gear steel, the effect of total oxygen content on nonmetallic inclusions in gear steel was studied. In this study, three kinds of Mn–Cr-system gear steels with different oxygen content were selected as research objects. The number, distribution, and size of nonmetallic inclusions in these gear steels were studied using an Aspex scanning electron microscope (Aspex SEM), the extreme value method, and fatigue test. The relationship between inclusions and the total oxygen content of gear steel was obtained. Under the experimental condition, with the decrease in total oxygen content, the density of the number of oxide inclusions decreases continuously, among which 5–10 μm small inclusions decrease most obviously. In contrast, the number density of large inclusions above 10 μm does not change obviously. Moreover, the results of the extreme value method and fatigue test show that when total oxygen mass fraction is high (0.0013%), the size of maximum oxide inclusion in the steel is relatively large, which is more than 10 μm higher than the inclusion in 0.0010% or 0.0005% total oxygen steel. Simultaneously, when total oxygen mass fraction is low (≤0.0010%), the change of total oxygen mass fraction (0.0010% and 0.0005%) has little effect on the maximum inclusion size in steel.

-

Key words:

- gear steel /

- total oxygen /

- nonmetallic inclusion /

- maximum size /

- extreme value method

-

表 1 實驗鋼的化學成分(質量分數)

Table 1. Chemical composition of experimental steel

% Steel No. C Si Mn Cr Al Ti P S O 1 0.18 0.07 1.23 1.21 0.02 <0.001 <0.015 <0.035 0.0013 2 0.17 0.07 1.22 1.22 0.03 <0.001 <0.015 <0.035 0.0010 3 0.17 0.07 1.24 1.24 0.03 <0.001 <0.015 <0.035 0.0005 中文字幕在线观看表 2 實驗鋼中氧化物夾雜數量密度

Table 2. Number density of oxide inclusions in test steels

mm–2 Steel No. 5–10 μm 10–15 μm 15–20 μm ≥20 μm Total 1 1.47 0.12 0.03 0.07 1.69 2 0.54 0.13 0.12 0.04 0.83 3 0.06 0.01 0 0 0.07 -

參考文獻

[1] Dengo C, Meneghetti G, Dabalà M. Experimental analysis of bending fatigue strength of plain and notched case-hardened gear steels. Int J Fatigue, 2015, 80: 145 doi: 10.1016/j.ijfatigue.2015.04.015 [2] Chen H, Zhou X Y. Research progress of gear steel for automobiles. J Mater Sci Eng, 2011, 29(3): 478陳暉, 周細應. 汽車齒輪鋼的研究進展. 材料科學與工程學報, 2011, 29(3):478 [3] Wang X H, Jiang M, Yu H X, et al. Investigation on non-metallic inclusions in ultra-low oxygen special steels. Steelmaking, 2015, 31(6): 1王新華, 姜敏, 于會香, 等. 超低氧特殊鋼中非金屬夾雜物研究. 煉鋼, 2015, 31(6):1 [4] Murakami Y, Yamashita Y. Prediction of life and scatter of fatigue failure originated at nonmetallic inclusions. Procedia Eng, 2014, 74: 6 doi: 10.1016/j.proeng.2014.06.214 [5] Murakami Y, Beretta S. Small defects and inhomogeneities in fatigue strength: experiments, models and statistical implications. Extremes, 1999, 2(2): 123 doi: 10.1023/A:1009976418553 [6] Krewerth D, Lippmann T, Weidner A, et al. Influence of non-metallic inclusions on fatigue life in the very high cycle fatigue regime. Int J Fatigue, 2016, 84: 40 doi: 10.1016/j.ijfatigue.2015.11.001 [7] Bathias C. There is no infinite fatigue life in metallic materials. Fatigue Fract Eng Mater Struct, 1999, 22(7): 559 doi: 10.1046/j.1460-2695.1999.00183.x [8] Xu K D. Certain basic subjects on clean steel. Acta Metall Sin, 2009, 45(3): 257 doi: 10.3321/j.issn:0412-1961.2009.03.001徐匡迪. 關于潔凈鋼的若干基本問題. 金屬學報, 2009, 45(3):257 doi: 10.3321/j.issn:0412-1961.2009.03.001 [9] Jiang M, Wang X H, Chen B, et al. Control of non-metallic inclusions in extra low oxygen special steel // Proceedings of the 9th China Steel Conference. Beijing, 2013: 1姜敏, 王新華, 陳斌, 等. 超低氧特殊鋼中非金屬夾雜物控制技術//第九屆中國鋼鐵年會論文集. 北京, 2013: 1 [10] Uesugi T. Recent development of bearing steel in Japan. Tetsu-To-Hagane, 1988, 74(10): 1889 doi: 10.2355/tetsutohagane1955.74.10_1889 [11] Uesugi T. Recent development of bearing steel in Japan. Trans Iron Steel Inst Jpn, 1988, 28(11): 893 doi: 10.2355/isijinternational1966.28.893 [12] Uesugi T. Production of high-carbon chromium bearing steel in vertical type continuous caster. Trans Iron Steel Inst Jpn, 1986, 26(7): 614 doi: 10.2355/isijinternational1966.26.614 [13] Tsubota K, Fukumoto I. Production and quality of high cleanliness bearing steel // Proceedings of the 6th International Iron and Steel Congress. Nagoya, 1990: 637. [14] Kawakami K, Taniguchi T, Nakashima K. Generation mechanisms of non-metallic inclusions in high-cleanliness steel. Tetsu-to-Hagané, 2007, 93(12): 743 [15] Yang J, Wang X H, Jiang M, et al. Effect of calcium treatment on non-metallic inclusions in ultra-low oxygen steel refined by high basicity high Al2O3 slag. J Iron Steel Res Int, 2011, 18(7): 8 doi: 10.1016/S1006-706X(11)60083-6 [16] Xu K D, Xiao L J. Deoxidation and inclusion control in special steel refining. Iron Steel, 2012, 47(10): 1徐匡迪, 肖麗俊. 特殊鋼精煉中的脫氧及夾雜物控制. 鋼鐵, 2012, 47(10):1 [17] Yang H L, He P, Zhai Y C. Progress on control of ultra-low-oxygen content and non-metallic inclusions in high quality bearing steel. Special Steel, 2013, 34(2): 16 doi: 10.3969/j.issn.1003-8620.2013.02.005楊虎林, 何平, 翟玉春. 高品質軸承鋼超低氧含量和非金屬夾雜物控制的進展. 特殊鋼, 2013, 34(2):16 doi: 10.3969/j.issn.1003-8620.2013.02.005 [18] Chen T M. Thermodynamic calculation and application of non-metallic inclusions for ultra-low-oxygen gear steel. Iron Steel, 2011, 46(4): 26陳天明. 超低氧齒輪鋼非金屬夾雜物控制熱力學計算及應用. 鋼鐵, 2011, 46(4):26 [19] Wang X H, Li J Z, Jiang M, et al. Investigation on technology of non-metallic inclusion control for high grade special steels of important uses. Steelmaking, 2017, 33(2): 50王新華, 李金柱, 姜敏, 等. 高端重要用途特殊鋼非金屬夾雜物控制技術研究. 煉鋼, 2017, 33(2):50 [20] Ohnishi T, Shiwaku K, Kawasaki S, et al. Production of high carbon chromium bearing steel in BOF-CC process. Tetsu-to-Hagané, 1987, 73(3): 513 [21] Wei P Y, Jiang M, Yang D, et al. Behavior of nonmetallic inclusions in ultra-low oxygen steel 25CrMoVNi for high speed rail axles during RH refining process. Special Steel, 2015, 36(3): 1 doi: 10.3969/j.issn.1003-8620.2015.03.001魏鵬遠, 姜敏, 楊疊, 等. 高速鐵路車軸用25CrMoVNi超低氧鋼RH精煉過程非金屬夾雜物的行為. 特殊鋼, 2015, 36(3):1 doi: 10.3969/j.issn.1003-8620.2015.03.001 [22] Yang J, Du J, Chen B T, et al. Influence of calcium treatment on oxide inclusions in ultra-low oxygen refining process. Iron Steel, 2015, 50(1): 19楊俊, 杜江, 陳波濤, 等. 超低氧精煉時鈣處理對氧化物夾雜的影響. 鋼鐵, 2015, 50(1):19 [23] Yang D, Jiang M, Lei S L, et al. Laboratory study on formation of complex inclusions in ultra-low oxygen steel. J Iron Steel Res, 2014, 26(1): 12楊疊, 姜敏, 雷少龍, 等. 超低氧鋼中復合夾雜物形成的實驗室研究. 鋼鐵研究學報, 2014, 26(1):12 [24] Dong W L, Ni H W, Zhang H, et al. Control of magnesia-alumina spinel inclusions in the ultra-low-oxygen gear steel 28MnCr5. J Iron Steel Res, 2015, 27(3): 14董文亮, 倪紅衛, 張華, 等. 超低氧齒輪鋼28MnCr5中鎂鋁尖晶石夾雜物的控制. 鋼鐵研究學報, 2015, 27(3):14 [25] Yu H X, Shao X J, Zhang J, et al. Study on the quantitative relationship between total oxygen content and non-metallic inclusion in steel with ASPEX SEM. Chin J Eng, 2015, 37(Suppl 1): 35于會香, 邵肖靜, 張靜, 等. 采用ASPEX掃描電鏡研究鋼中總氧和非金屬夾雜物的定量關系. 工程科學學報, 2015, 37(增刊 1):35 [26] Murakami Y, Toriyama T, Coudert E. Instructions for a new method of inclusion rating and correlations with the fatigue limit. J Test Eval, 1994, 22(4): 318 doi: 10.1520/JTE11840J [27] Beretta S, Murakami Y. Statistical analysis of defects for fatigue strength prediction and quality control of materials. Fatigue Fract Eng Mater Struct, 1998, 21(9): 1049 doi: 10.1046/j.1460-2695.1998.00104.x [28] Shi G, Atkinson H V, Sellars C M, et al. Comparison of extreme value statistics methods for predicting maximum inclusion size in clean steels. Ironmaking Steelmaking, 1999, 26(4): 239 doi: 10.1179/030192399677095 -

下載:

下載: