-

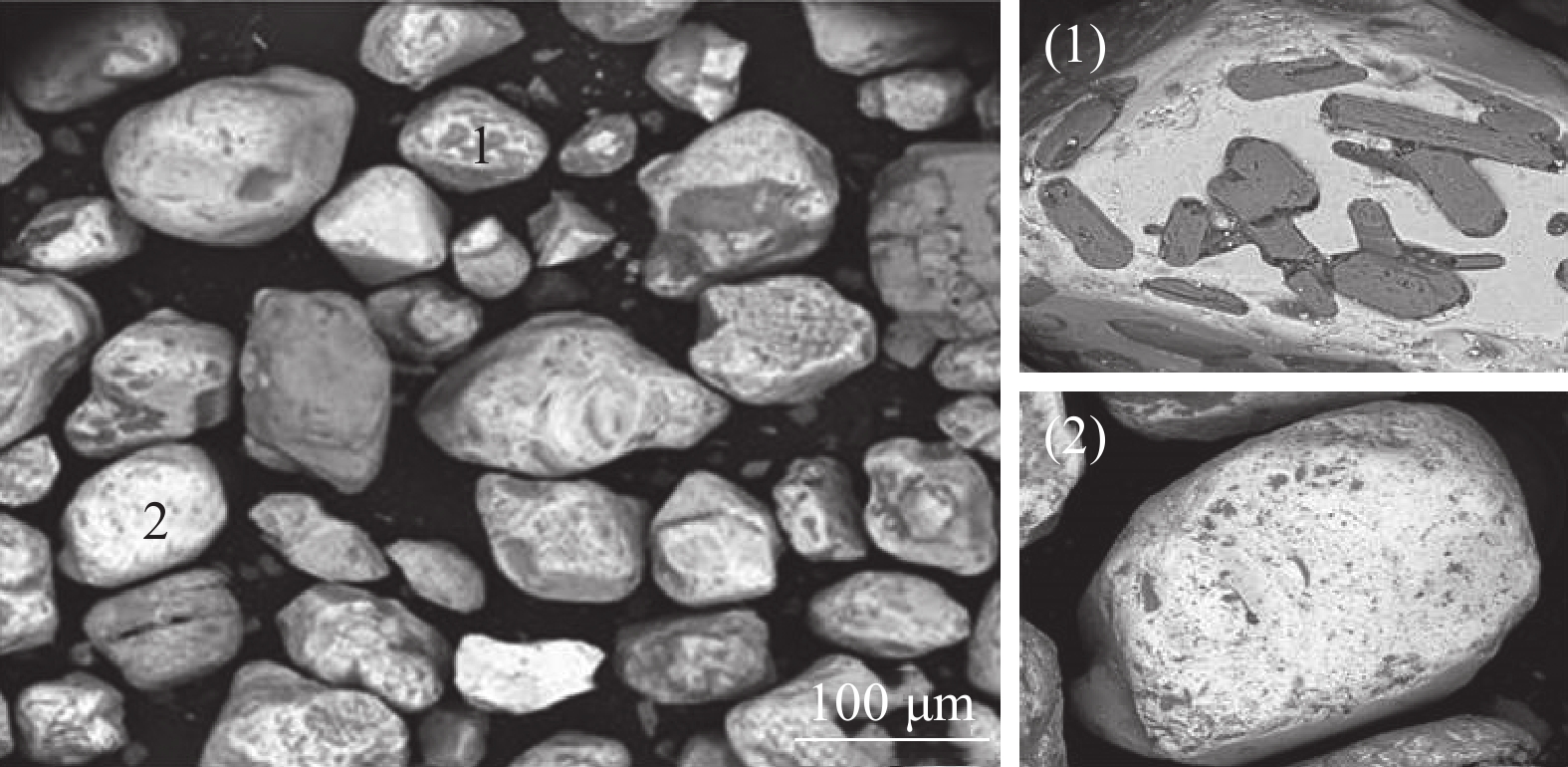

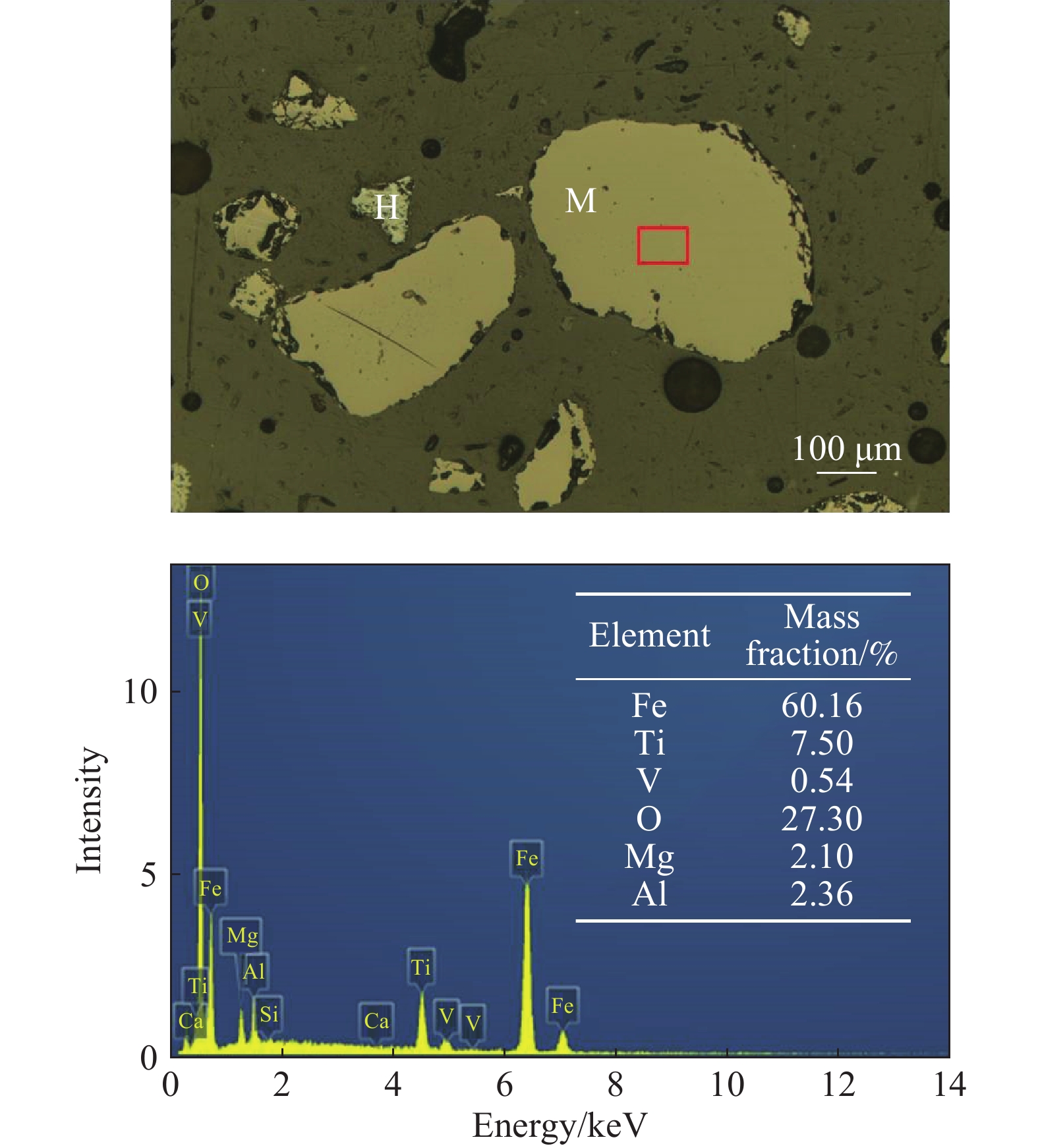

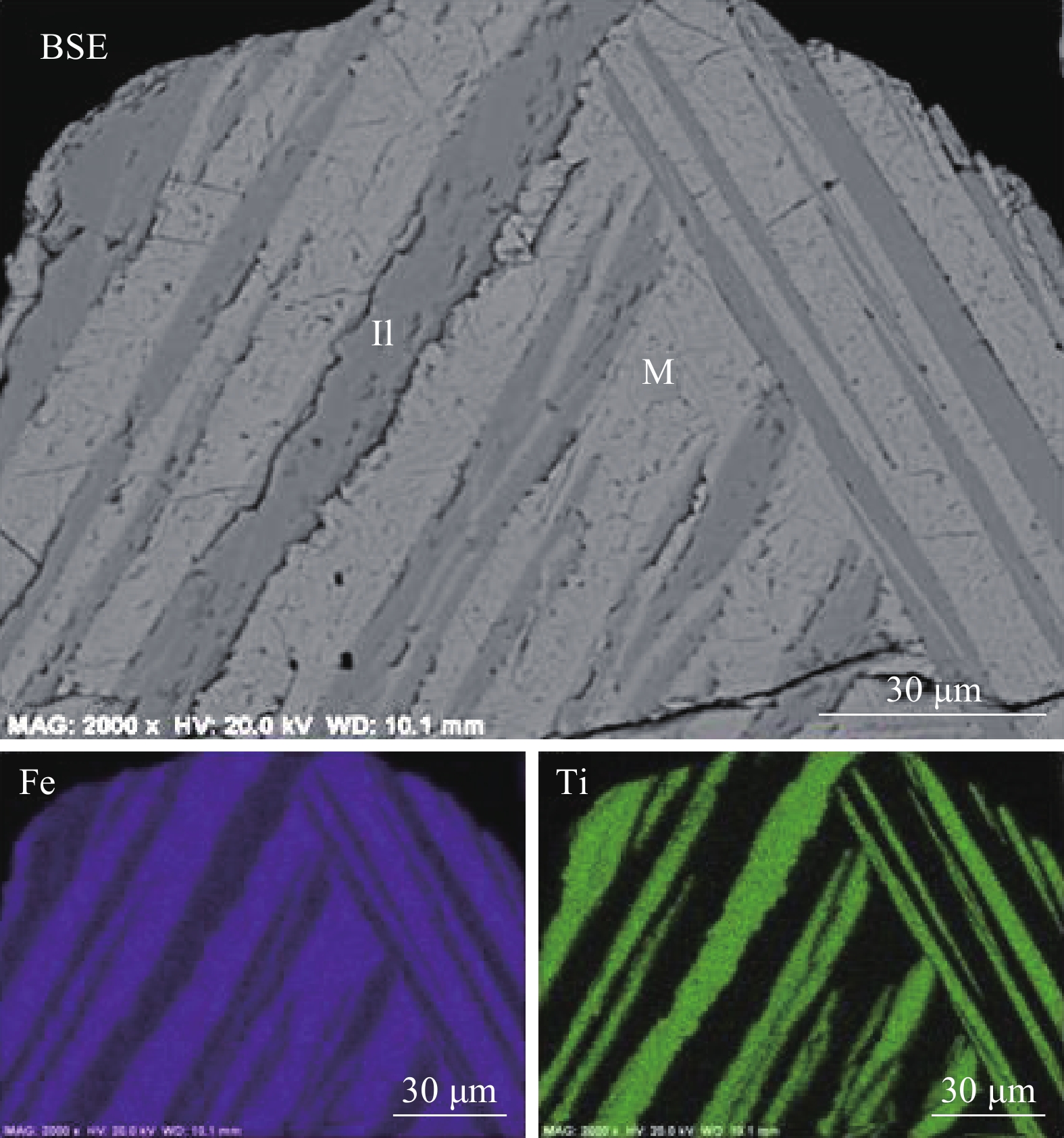

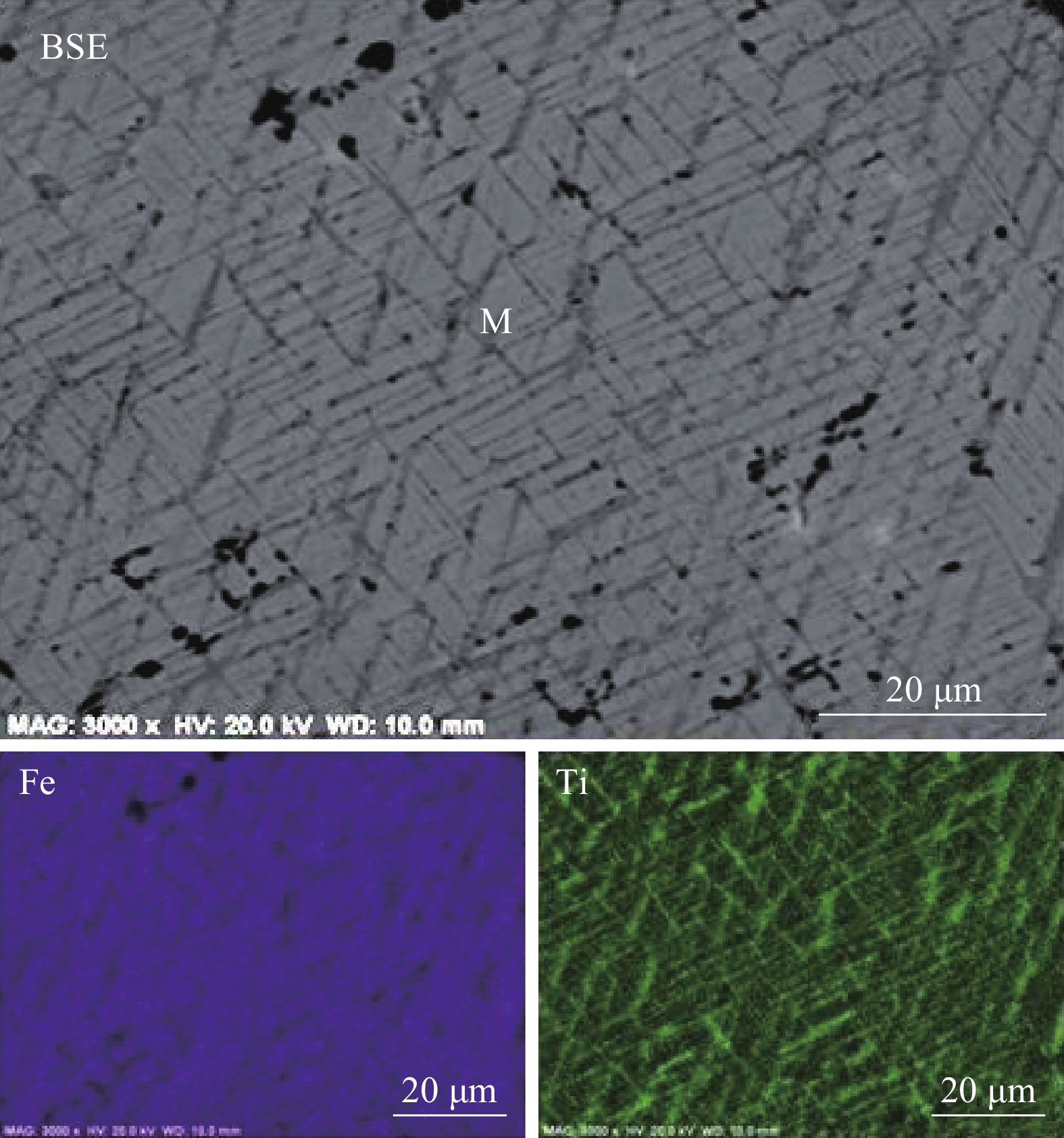

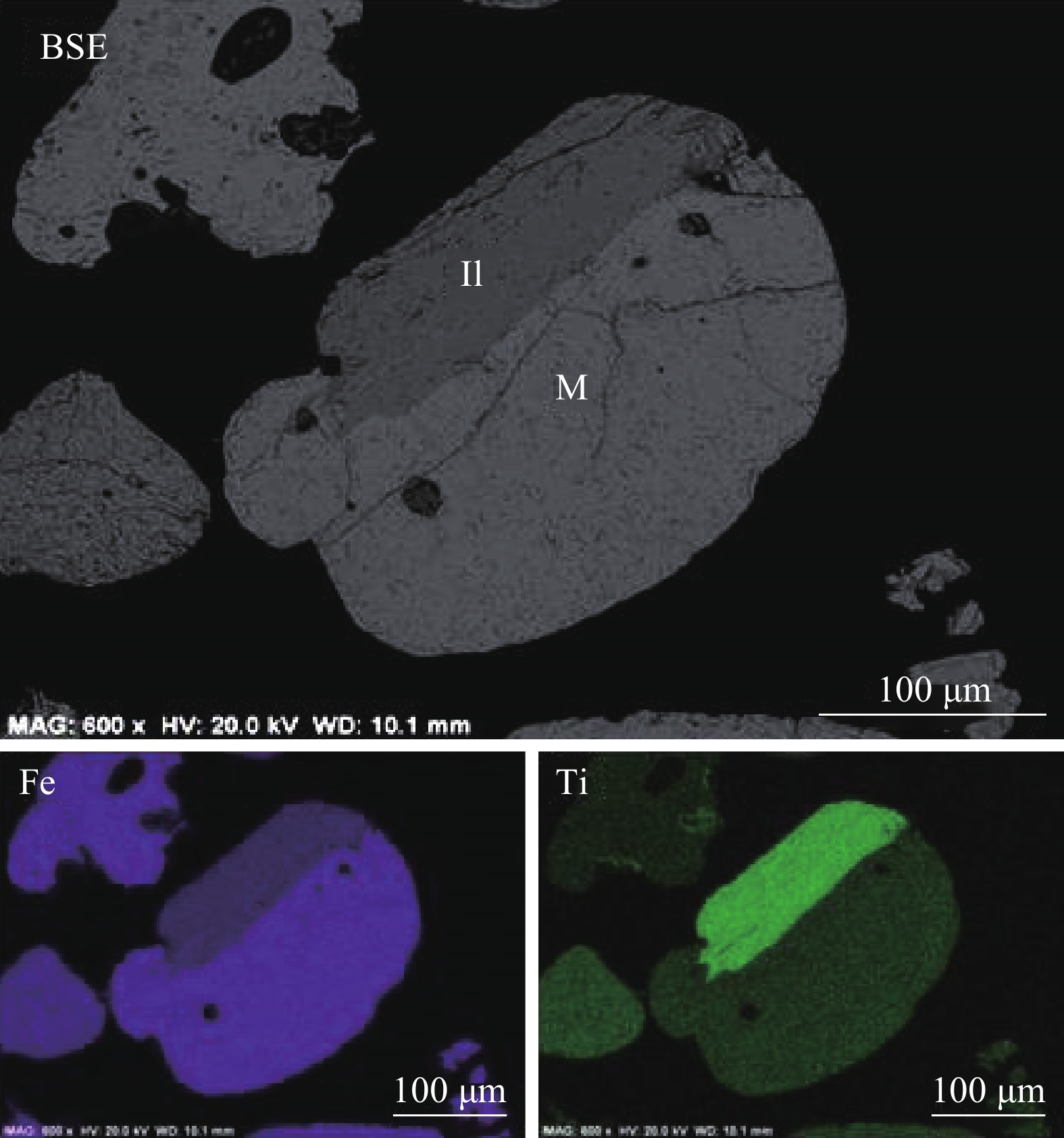

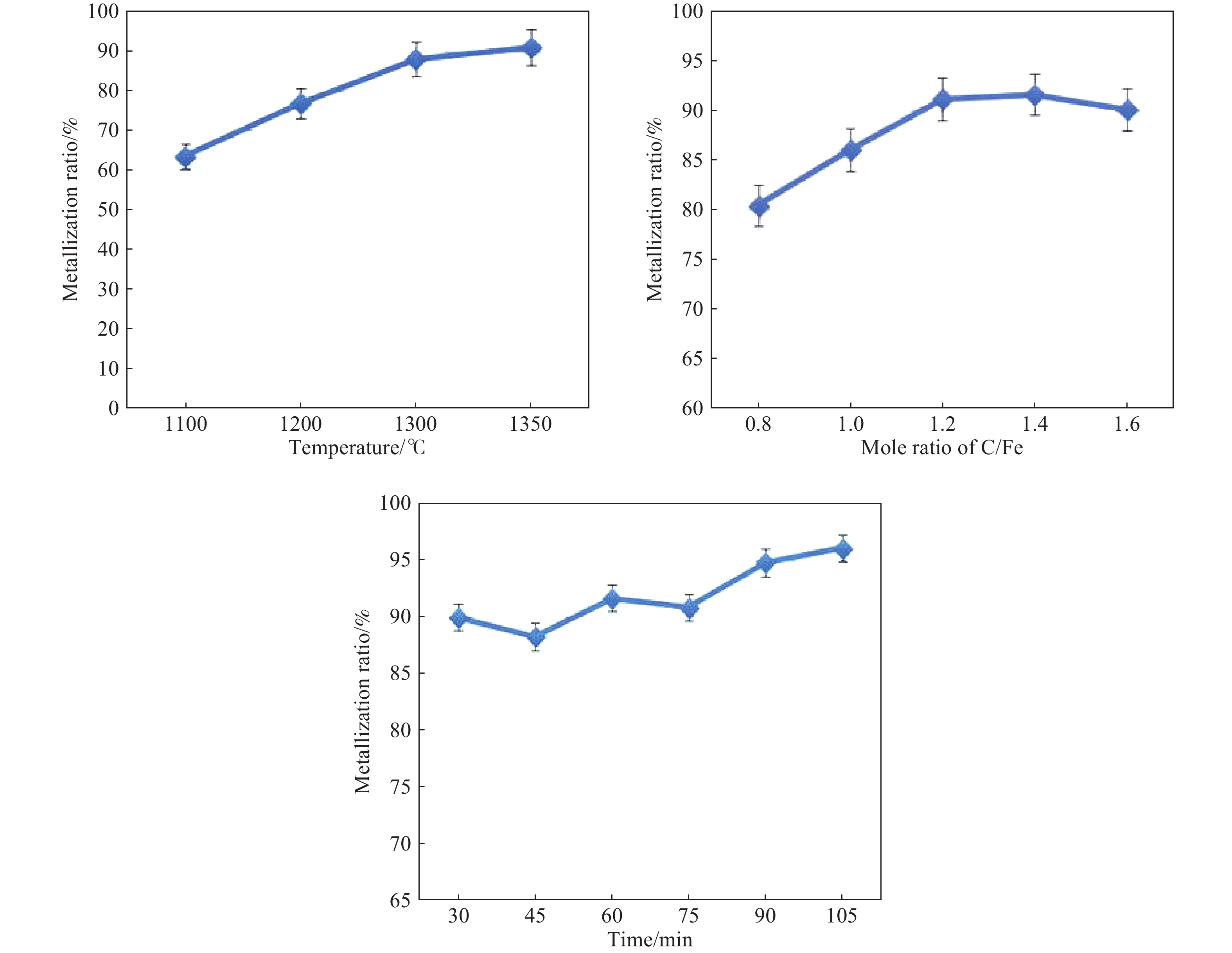

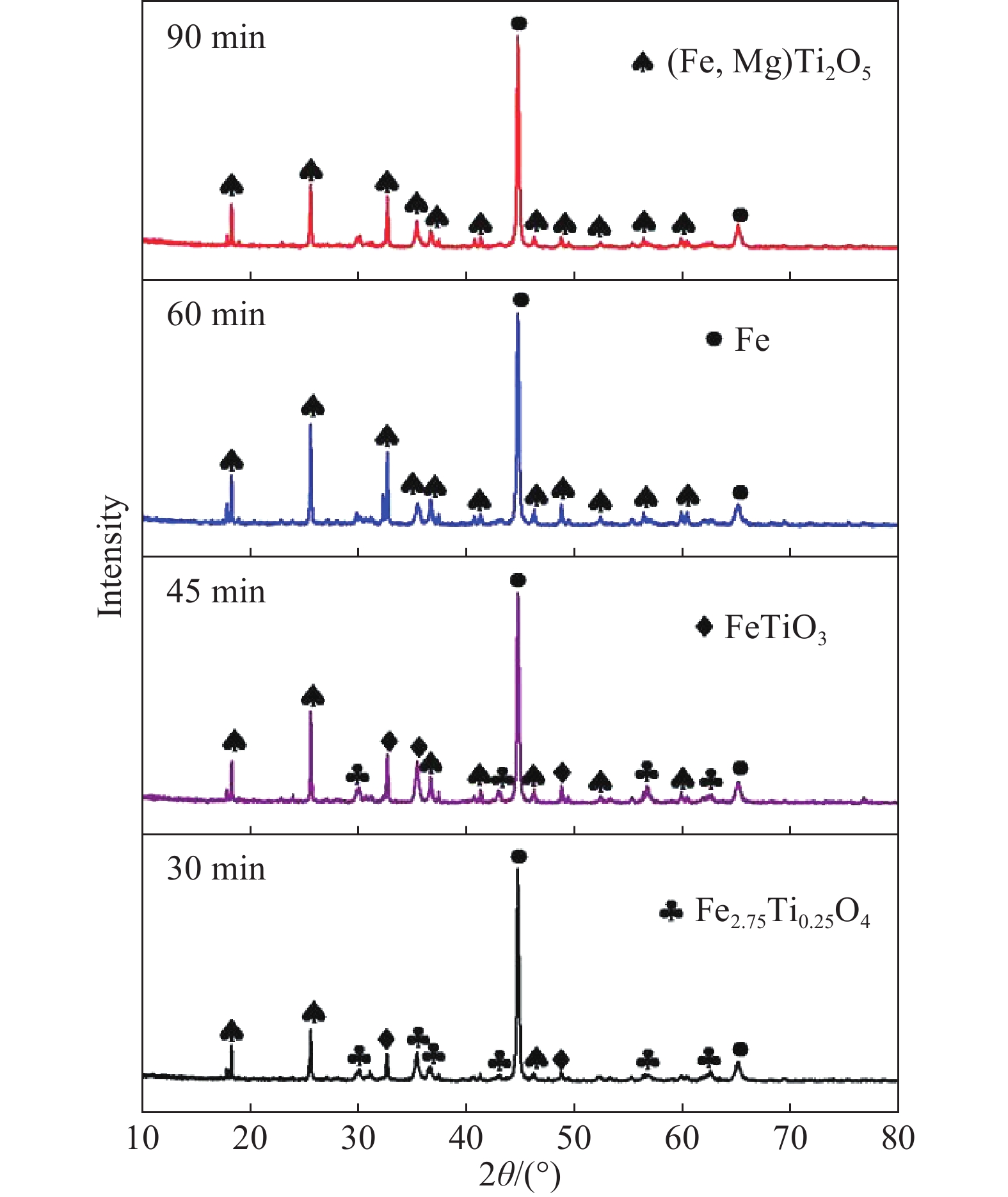

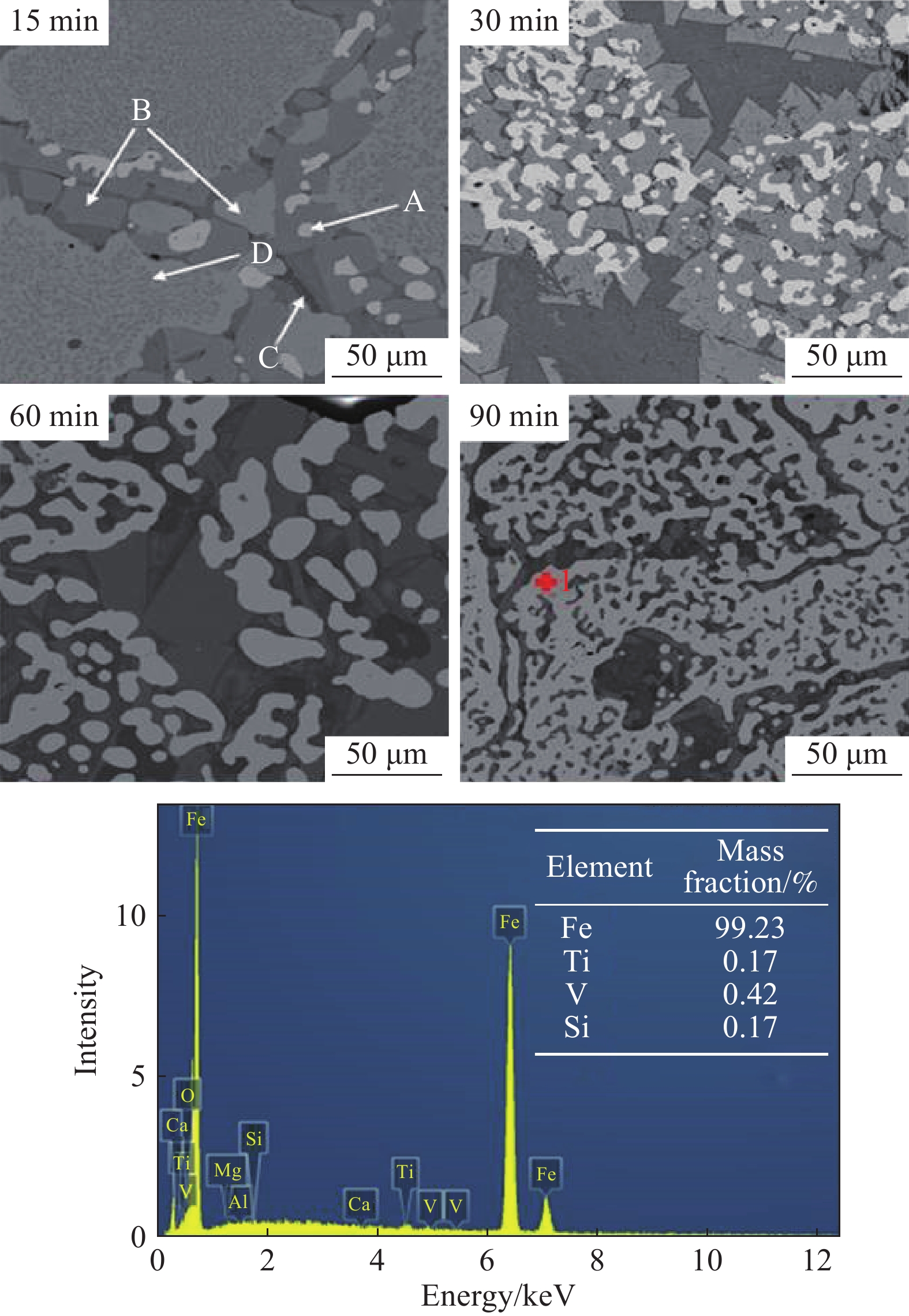

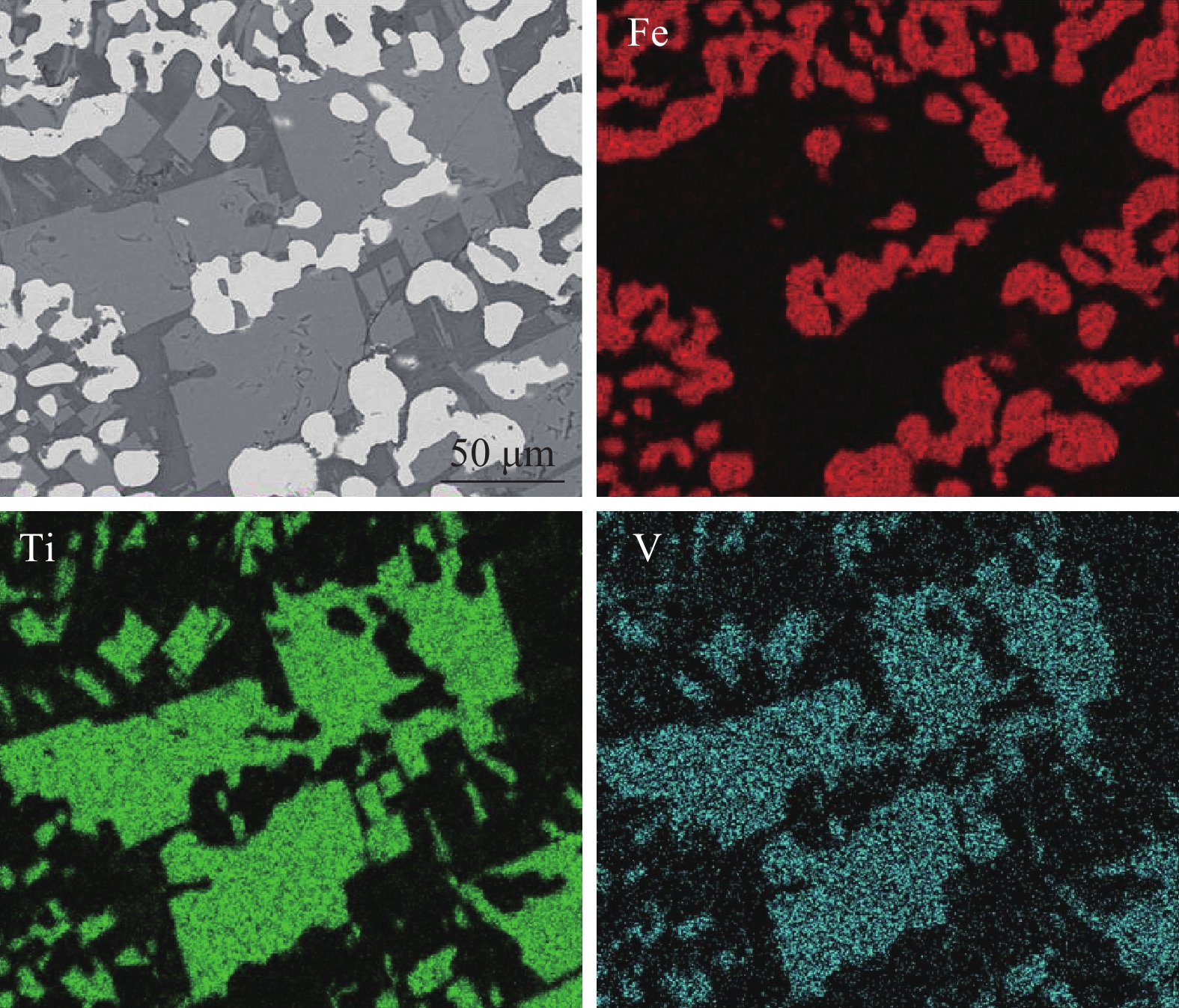

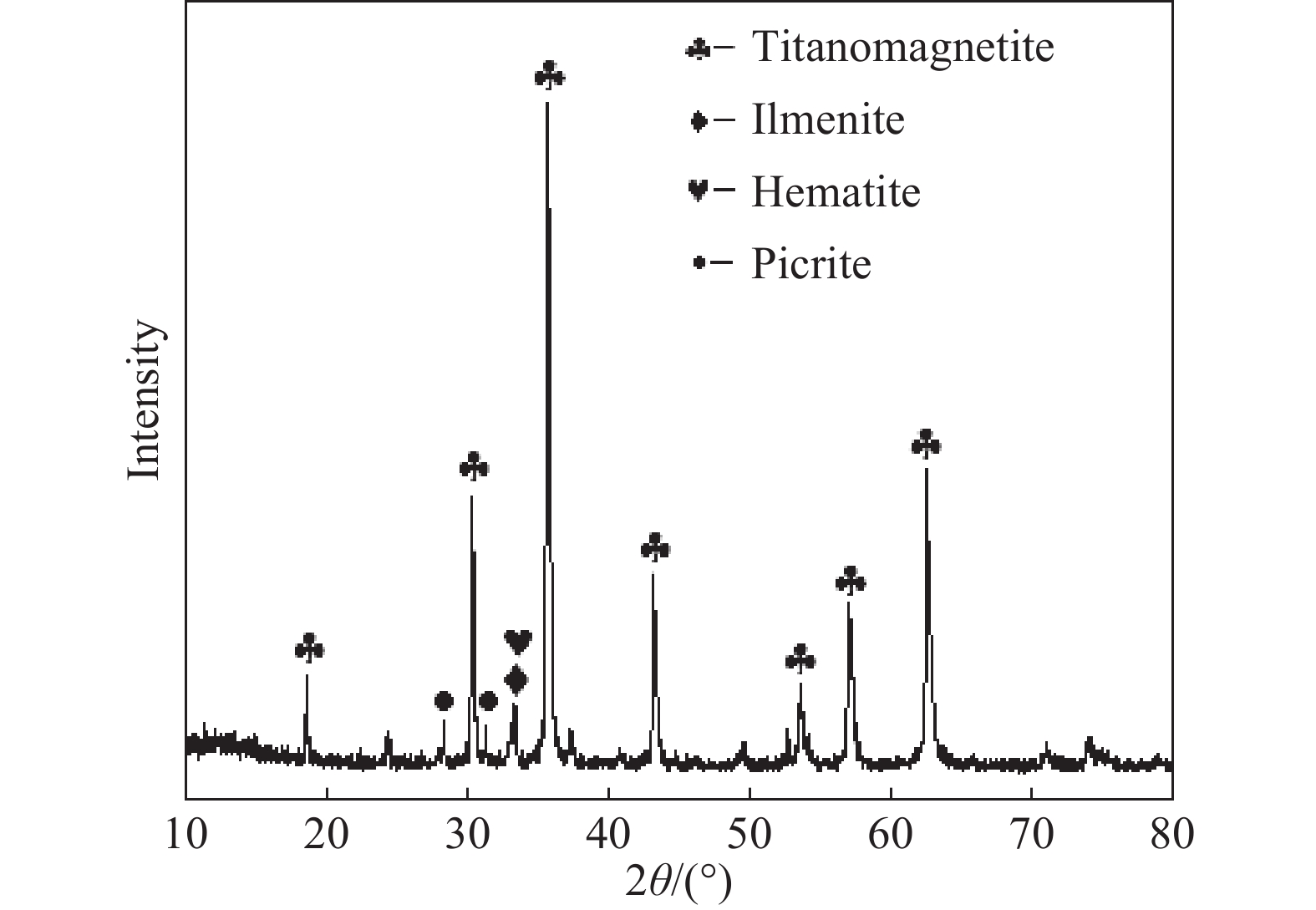

摘要: 以經典工藝礦物學研究方法為基礎,結合化學物相分析、礦物解離分析(MLA)、X射線衍射、光學顯微鏡、掃描電鏡-X射線能譜儀(SEM-EDS)等手段對印尼典型海砂礦的礦物學及其固態還原特征進行了系統研究。結果表明:印尼海砂礦的礦物組成主要為鈦磁鐵礦、次為少量假象赤鐵礦、赤鐵礦、鈦鐵礦以及輝石等。絕大部分鈦磁鐵礦呈致密單體或鐵的富連生體產出,偶有由固熔體分離析出形成的微細鈦鐵礦片晶。賦存于鈦磁鐵礦中的鐵占總鐵的89.79%、鈦為85.42%、釩則高達97.97%。海砂礦在C/Fe摩爾比1.2、溫度1300 ℃條件下還原60 min可較好實現金屬化。其還原歷程遵循:Fe2.75Ti0.25O4 → FeTiO3, (Fe, Mg)Ti2O5 → (Fe, Mg)Ti2O5 → Fe,穩定的黑鈦石相是影響金屬化程度的主要因素。經固態還原處理Fe元素最終富集于金屬相,V、Ti則賦存于渣中富鈦相,為后續的分離提取創造了有利條件。Abstract: With over 100 billion tons of reserves, the ironsands resource is mainly distributed along the “Belt and Road” countries, such as Indonesia. It is the second largest marine resource inferior to petroleum and natural gas. Ironsands mainly comprise vanadium, titanium, and iron. With advantages of easy mining, low cost, and abundance in polymetallic minerals, the ironsands resource has attracted extensive attention for its extremely high comprehensive recycling value. According to previous studies, solid-state reduction is an efficient approach to a number of processes in complex mineral resources such as ironsands, especially in vanadium-bearing titanomagnetite treatments. In this paper, the process mineralogy and direct reduction characteristics of typical ironsands from Indonesia were studied based on the classical mineralogy method combined with various characterization techniques such as chemical phase analysis, MLA, X-ray diffraction, particle size analysis, optical microscopy, and SEM-EDS. Results show that the mineral composition of the ironsands is mainly titanomagnetite, followed by a small amount of pseudo-hematite, hematite, ilmenite, pyroxene, plagioclase, and others. Most titanomagnetites exist as compact monomers or iron-rich aggregates with occasional fine ilmenite flakes formed through solid-melt separation. The iron contained in titanomagnetite phase accounts for 89.79% of the total iron in the ironsands, while titanium and vanadium account for 85.42% of the total titanium and 97.97% of the total vanadium content, respectively. Ironsands can achieve high metallization ratio when they are reduced at 1300 ℃ for 60 min with C/Fe mole ration of 1.2. The reduction course is as follows: Fe2.75Ti0.25O4 → FeTiO3, (Fe, Mg)Ti2O5 → (Fe, Mg)Ti2O5 → Fe. Results reveal that the stable anosovite ((Fe, Mg)Ti2O5) phase is the main factor affecting the final metallization degree of the reduced samples. With solid state reduction treatment, iron is enriched in the metal phase while vanadium and titanium elements are distributed in the titanium-rich phase in the slag. These create favorable conditions for the subsequent separation and extraction process, which consequently lay a firm foundation for the comprehensive utilization of the ironsands.

-

表 1 印尼海砂礦的主要化學成分(質量分數)

Table 1. Chemical composition of Indonesia ironsands

% TFe FeO Fe2O3 TiO2 V2O5 SiO2 Al2O3 MgO 54.48 29.08 45.27 10.88 0.68 4.01 3.67 3.68 CaO MnO Na2O K2O S P LOI 0.48 0.44 0.079 0.020 0.059 0.027 0.29 表 2 印尼海砂礦的粒度組成

Table 2. Size distribution of Indonesia ironsands

Particle size/mm Mass fraction/% >0.15 46.42 0.074–0.15 52.14 0.045–0.074 0.78 <0.045 0.56 表 3 還原煤的工業分析(質量分數)

Table 3. Proximate analysis of reducing coal

% Moisture Volatiles Fixed carbon Ash 2.64 10.36 75.66 11.34 表 4 海砂礦中主要目的礦物的解離度

Table 4. Liberation degree of main target minerals in ironsand

Mineral Single particle/% Intergrowth particles/% >3/4 3/4–1/2 1/2–1/4 <1/4 Magnetite 76.62 21.28 1.06 0.70 0.34 Ilmenite 62.35 32.84 1.20 1.33 2.28 表 5 鈦磁鐵礦和鈦鐵礦連生體與嵌連礦物的比例(質量分數)

Table 5. Intergrowth minerals ratios of titanomagnetite and ilmenite

% Mineral Magnetite Ilmenite Rutile Picrite Quartz Feldspar Phosphorite Others Magnetite 13.73 4.88 43.99 2.98 13.83 10.55 10.04 Ilmenite 67.34 3.47 10.83 0.51 3.28 7.47 7.10 中文字幕在线观看表 6 樣品中Fe, Ti, V分布平衡概算

Table 6. Estimated results of the Fe distribution balance in the sample

Mineral Mass fraction (MF)/% Fe Ti V MF/% Distribution/% MF/% Distribution/% MF/% Distribution/% Magnetite 83.21 58.92 89.79 11.23 85.42 0.78 97.97 Hematite 6.93 62.11 7.87 8.87 5.62 0.17 1.85 Ilmenite 1.87 35.59 1.22 50.94 8.71 0.06 0.18 Picrite 5.62 10.93 1.12 0.49 0.25 Others 2.37 — — — — — — Total 100.00 54.67 100.00 10.94 100.00 0.64 100.00 Raw ore 54.27 10.88 0.68 Balance index 1.01 1.01 0.94 -

參考文獻

[1] Tan Q X. China’s marine placer deposits. Geol China, 1998(4): 23譚啟新. 中國的海洋砂礦. 中國地質, 1998(4):23 [2] Bai F L, He Y J, Li J. Ironsand resources exploration, mining and sustainable development of China. Miner Deposits, 2010, 29(Suppl 1): 771白鳳龍, 何擁軍, 李軍. 中國海砂資源勘查、開采與可持續發展. 礦床地質, 2010, 29(增刊 1):771 [3] Deng G Z. Status of world titanium resources and its development and utilization. Tit Ind Prog, 2002(5): 9 doi: 10.3969/j.issn.1009-9964.2002.05.003鄧國珠. 世界鈦資源及其開發利用現狀. 鈦工業進展, 2002(5):9 doi: 10.3969/j.issn.1009-9964.2002.05.003 [4] Sun L J, Lü X J, Chen P, et al. Experimental study on the mineralogical characteristics and processing technique of a beach placer. Min Res Dev, 2010, 30(2): 62孫麗君, 呂憲俊, 陳平, 等. 某海濱砂礦的礦物學特征與選礦試驗研究. 礦業研究與開發, 2010, 30(2):62 [5] Liu Y R, Zhang J L, Wang Z Y, et al. Experimental research on the deep reduction?magnetic separation of ironsand. Chin J Eng, 2016, 38(2): 181劉依然, 張建良, 王振陽, 等. 海砂礦深度還原?磁選分離實驗研究. 工程科學學報, 2016, 38(2):181 [6] Liu S S, Guo Y F, Qiu G Z, et al. Solid-state reduction kinetics and mechanism of pre-oxidized vanadium?titanium magnetite concentrate. Trans Nonferrous Met Soc China, 2014, 24(10): 3372 doi: 10.1016/S1003-6326(14)63479-8 [7] Zhang Y P, Zhang J L, Wang Z Y, et al. Sintering characteristics of titanium sands after grinding and its influence mechanism on the quality of sinter. Chin J Eng, 2016, 38(4): 468張亞鵬, 張建良, 王振陽, 等. 細磨海砂礦燒結特性及其對燒結礦質量影響機理. 工程科學學報, 2016, 38(4):468 [8] Liao X F, Zhang L B, Peng J H, et al. Carbothermic reduction of marine placer with additional aluminum. Powder Technol, 2017, 311: 34 doi: 10.1016/j.powtec.2017.01.086 [9] Liu Y R, Zhang J L, Wang Z Y, et al. Feasibility of the synergistic utilization of ironsand and blast furnace bag dust. Iron Steel Van Tit, 2015, 36(5): 87 doi: 10.7513/j.issn.1004-7638.2015.05.017劉依然, 張建良, 王振陽, 等. 海砂礦和高爐粉塵復合造塊還原試驗. 鋼鐵釩鈦, 2015, 36(5):87 doi: 10.7513/j.issn.1004-7638.2015.05.017 [10] Li Y Q, Li L, Guo H J, et al. Experimental research on the preparation of oxidized pellets with Indonesian beach placer. Min Metall Eng, 2015, 35(2): 124 doi: 10.3969/j.issn.0253-6099.2015.02.031李永麒, 李林, 郭漢杰, 等. 印尼某海砂礦氧化性球團制備試驗研究. 礦冶工程, 2015, 35(2):124 doi: 10.3969/j.issn.0253-6099.2015.02.031 [11] Zeng L M, Ou L M. Flotation process and process mineralogy analysis of certain zinc sulfide ore. Chin J Nonferrous Met, 2018, 28(9): 1867曾令明, 歐樂明. 某硫化鋅礦浮選新工藝及工藝礦物學特性分析. 中國有色金屬學報, 2018, 28(9):1867 [12] Yang H Y, Li X J, Tong L L, et al. Process mineralogy of high lead copper anode slime. Chin J Nonferrous Met, 2014, 24(1): 269楊洪英, 李雪嬌, 佟琳琳, 等. 高鉛銅陽極泥的工藝礦物學. 中國有色金屬學報, 2014, 24(1):269 [13] Wang X, Qin W Q, Jiao F, et al. Mineralogy and pretreatment of a refractory gold deposit in Zambia. Minerals, 2019, 9(7): 406 doi: 10.3390/min9070406 [14] Schulz B, Merker G, Gutzmer J. Automated SEM mineral liberation analysis (MLA) with generically labelled EDX spectra in the mineral processing of rare earth element ores. Minerals, 2019, 9(9): 527 doi: 10.3390/min9090527 [15] Zhou W T, Han Y X, Li Y J, et al. Process mineralogy and grinding optimization of cassiterite polymetallic sulphide ore. J Cent South Univ Sci Technol, 2019, 50(6): 1271 doi: 10.11817/j.issn.1672-7207.2019.06.001周文濤, 韓躍新, 李艷軍, 等. 錫石多金屬硫化礦工藝礦物學及磨礦優化. 中南大學學報(自然科學版), 2019, 50(6):1271 doi: 10.11817/j.issn.1672-7207.2019.06.001 [16] Yu H D, Wang L N, Qu J K, et al. Process mineralogical characteristics and ore value of typical vanadium titanium magnetite in China. J Northeast Univ Nat Sci, 2020, 41(2): 275 doi: 10.12068/j.issn.1005-3026.2020.02.022于宏東, 王麗娜, 曲景奎, 等. 中國典型釩鈦磁鐵礦的工藝礦物學特征與礦石價值. 東北大學學報(自然科學版), 2020, 41(2):275 doi: 10.12068/j.issn.1005-3026.2020.02.022 [17] Liang Z K, Yi L Y, Huang Z C, et al. A novel and green metallurgical technique of highly efficient iron recovery from refractory low-grade iron ores. ACS Sustainable Chem Eng, 2019, 7(22): 18726 doi: 10.1021/acssuschemeng.9b05423 [18] Guo Y F. Study on Strengthening of Solid-State Reduction and Comprehensive Utilization of Vanadiferous Titanomagnetite [Dissertation]. Changsha: Central South University, 2007郭宇峰. 釩鈦磁鐵礦固態還原強化及綜合利用研究[學位論文]. 長沙: 中南大學, 2007 [19] Institute of Comprehensive Utilization of Mineral Resources, Chinese Academy of Geological Sciences. Vanadium-Titanomagnetite Resource in Panxi and Its Comprehensive Utilization Technology. Beijing: Metallurgical Industry Press, 2015中國地質科學院礦產綜合利用研究所. 攀西釩鈦磁鐵礦資源及綜合利用技術. 北京: 冶金工業出版社, 2015 [20] Yi L Y, Huang Z C, Jiang T, et al. Carbothermic reduction of ferruginous manganese ore for Mn/Fe beneficiation: Morphology evolution and separation characteristic. Minerals, 2017, 7(9): 167 doi: 10.3390/min7090167 [21] Sui Y L, Guo Y F, Jiang T, et al. Separation and recovery of iron and titanium from oxidized vanadium titano-magnetite by gas-based reduction roasting and magnetic separation. J Mater Res Technol, 2019, 8(3): 3036 doi: 10.1016/j.jmrt.2018.05.031 [22] Safdar F, Zhang Y, Zheng S L, et al. Recovery of TiO2-enriched material from vanadium titano-magnetite concentrates by partial carbon reduction and mild acid leaching. Hydrometallurgy, 2020, 193: 105324 doi: 10.1016/j.hydromet.2020.105324 [23] Li Y, Liu Y S, Liu J W, et al. Panzhihua vanadium titanium magnetite mineralization geological characteristics and metallogenic regularity. World Nonferrous Met, 2017(1): 95李玥, 劉嚴松, 劉建偉, 等. 攀枝花釩鈦磁鐵礦成礦地質特征與成礦規律初探. 世界有色金屬, 2017(1):95 [24] Guo D J, Yu H J, Meng B, et al. Ore-bearing rock features and metallogenic regularity of Panzhihua vanadium-titanium magnetite. Acta Mineral Sin, 2013(Suppl 1): 91郭道軍, 于海軍, 孟標, 等. 攀枝花釩鈦磁鐵礦含礦巖體特征與成礦規律. 礦物學報, 2013(增刊 1):91 [25] Liu S L, Bai C G, Hu T, et al. Quick and direct reduction process of vanadium and titanium iron concentrate with carbon-containing pellets at high temperature. J Chongqing Univ Nat Sci Ed, 2011, 34(1): 60 doi: 10.11835/j.issn.1000-582X.2011.01.010劉松利, 白晨光, 胡途, 等. 釩鈦鐵精礦內配碳球團高溫快速直接還原歷程. 重慶大學學報, 2011, 34(1):60 doi: 10.11835/j.issn.1000-582X.2011.01.010 -

下載:

下載: