-

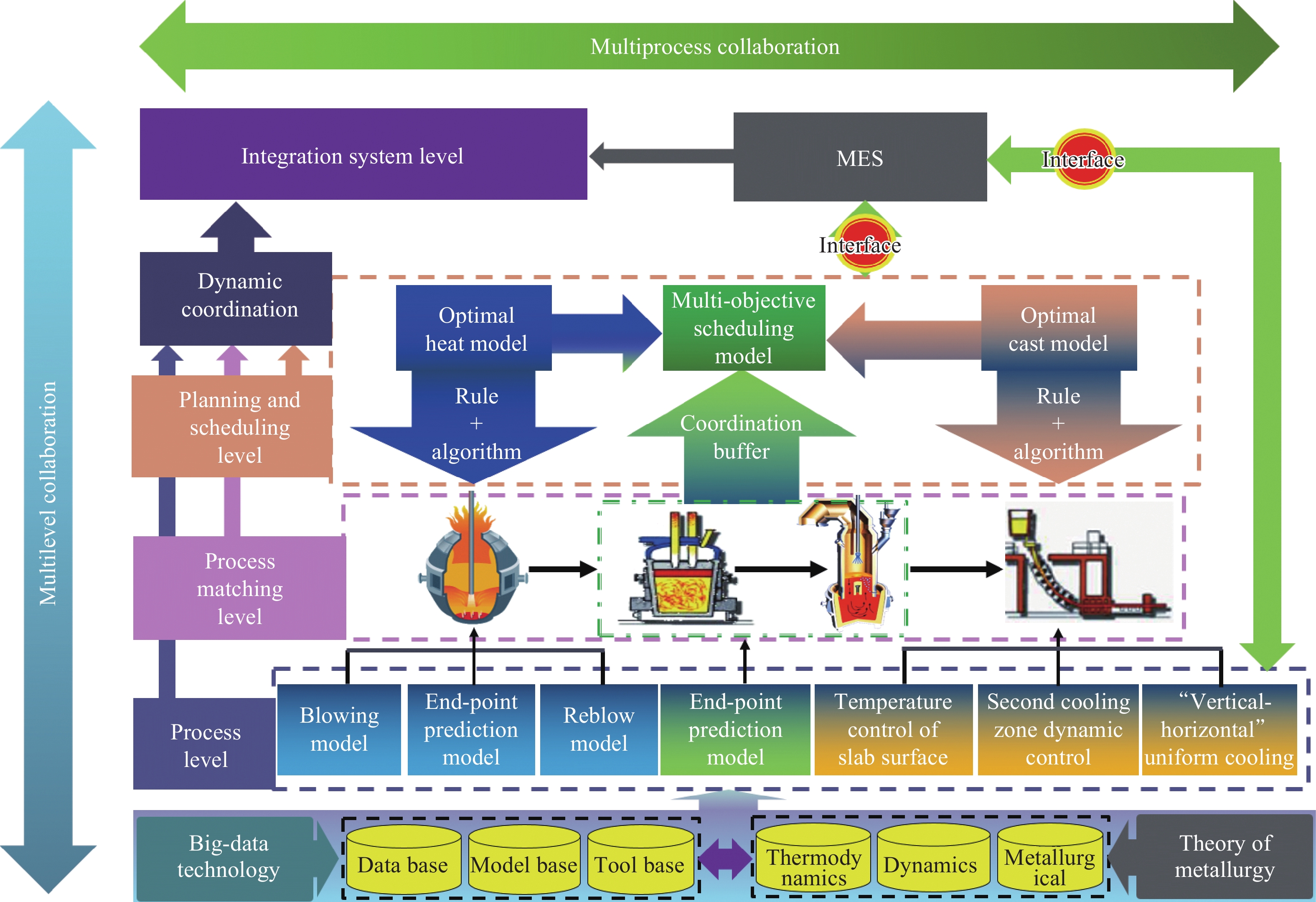

摘要: 在闡述煉鋼廠多尺度建模與協同制造技術架構的基礎上,分別從單體工序尺度、車間區段尺度與煉鋼廠運行尺度開展了煉鋼廠協同制造的研究。從工序/裝置過程控制系統(PCS)到煉鋼廠制造執行系統(MES)進行了較為系統的建模研發,構建了包括轉爐工序、精煉工序與連鑄工序在內的工序工藝控制模型以及以生產計劃與調度模型為核心的物質流運行優化模型,并通過工序工藝控制和生產計劃與調度的動態協同,實現了煉鋼廠多工序/裝置的高效運行。研發了煉鋼?連鑄過程工序工藝控制模型、生產計劃與調度模型同MES之間的數據接口,實現了MES與生產工藝控制、流程運行控制、生產計劃與調度系統的有機融合,形成了以機理模型與數據模型協同驅動的工藝精準控制、多工序協同運行、基于“規則+算法”的生產計劃與調度為支撐的煉鋼?連鑄過程集成制造技術,通過多層級的縱向協同與多工序的橫向協同,實現了煉鋼廠的協同運行與控制。研究成果是煉鋼?連鑄過程智能制造的有益探索與實踐,對流程工業智能制造企業具有很強的參考價值,對冶金工業綠色化、智能化發展具有示范與借鑒作用。應用后,明顯提升了煉鋼廠的協同制造水平,取得了顯著的經濟與社會效益。Abstract: With the recent, rapid developments of metallurgical theory and intelligent steelmaking technology, the intelligent upgrading of iron and steel enterprises has attracted increased attention and become a topic of discussion in the steel industry. Collaborative manufacturing is an important feature of intelligent manufacturing in steel enterprises, and it plays an important role in improving the production efficiency and reducing the carbon emissions of iron and steel enterprises. This study elaborated the structure and the contents of multiscale modeling and the collaborative manufacturing of steelmaking plants in detail. The collaborative control of steelmaking plants was studied from the scales of individual processes, workshop sections, and the operation of steelmaking plants. Systematic modeling studies had been conducted from the process control system of processes/devices to the manufacturing execution system (MES). The process control models, including the converter steelmaking process, secondary metallurgy process, and continuous casting process, and mass flow operation optimization models with the production planning and scheduling model as the core were established. In addition, the high-efficiency operation of multi processes/devices was realized through the dynamic coordination of process control and production planning and scheduling in the steelmaking plants. The data interface between process control models, production planning and scheduling models, and MES had been developed to realize the comprehensive integration of MES, production process control, process operation control, production planning, and scheduling system. It had formed the steelmaking-continuous casting process integrated manufacturing technology supported by the precise process control co-driven by mechanism and data models, collaborative process operation, and production planning and scheduling based on “rules + algorithms.” Through multilevel vertical coordination and multiprocess horizontal coordination, the coordinated operation and the control of steelmaking plants were realized. The study results demonstrated a beneficial exploration and the practice of intelligent manufacturing in the steelmaking-continuous casting process, which had strong reference value for intelligent manufacturing enterprises in the process industry, and had a demonstration effect for the green and the intelligent development of the metallurgical industry. After the application, the collaborative manufacturing level of the steelmaking plant had been considerably improved, and significant economic and social benefits had been achieved.

-

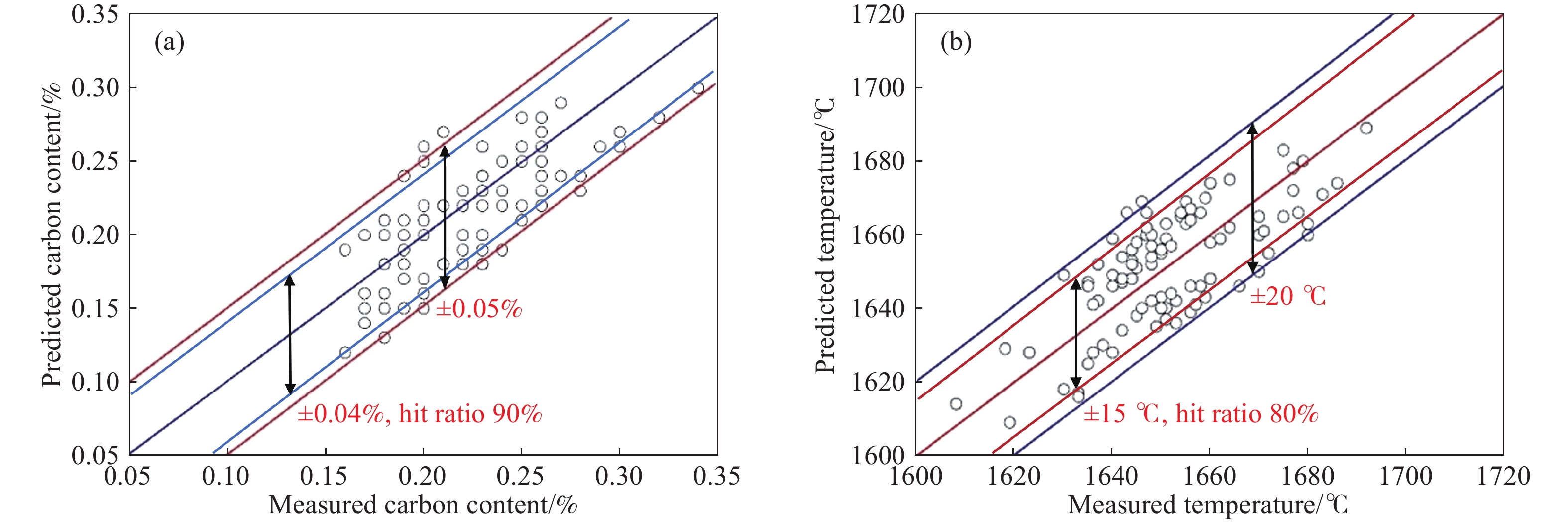

圖 2 基于熔池混勻度的轉爐冶煉過程模型驗證. (a)碳含量預報; (b)溫度預報[15]

Figure 2. Validation of converter steelmaking process model based on molten bath mixing degree: (a) carbon content prediction; (b) temperature prediction

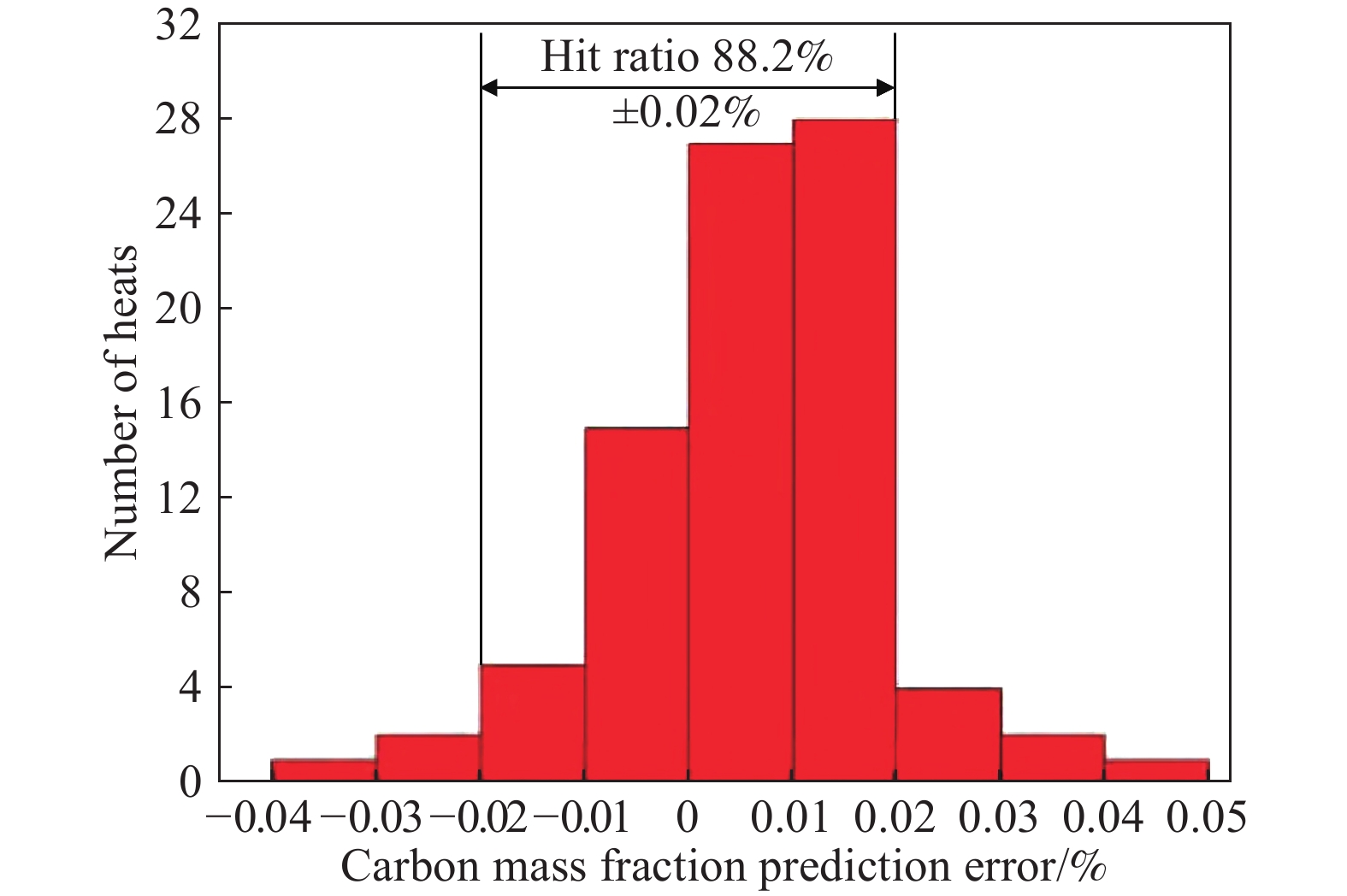

圖 3 基于熔池混勻度的指數模型終點碳含量預報誤差分布[5]

Figure 3. Prediction error distribution of end-point carbon content of the exponential model based on bath mixing degree

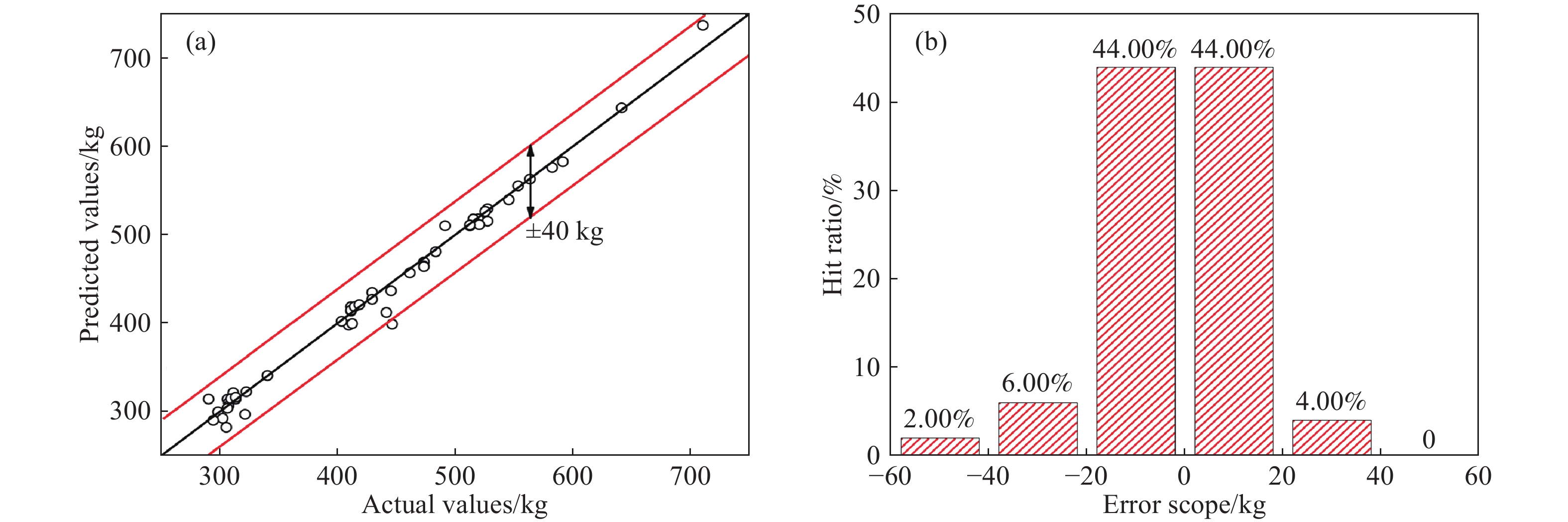

圖 4 LF精煉造渣模型預報結果. (a) 石灰加入量預報; (b)石灰加入量命中率[8]

Figure 4. Prediction results of LF refining slag-making model: (a) comparison between the calculated and actual weights of lime; (b) hit ratio of predicting the required weight of lime

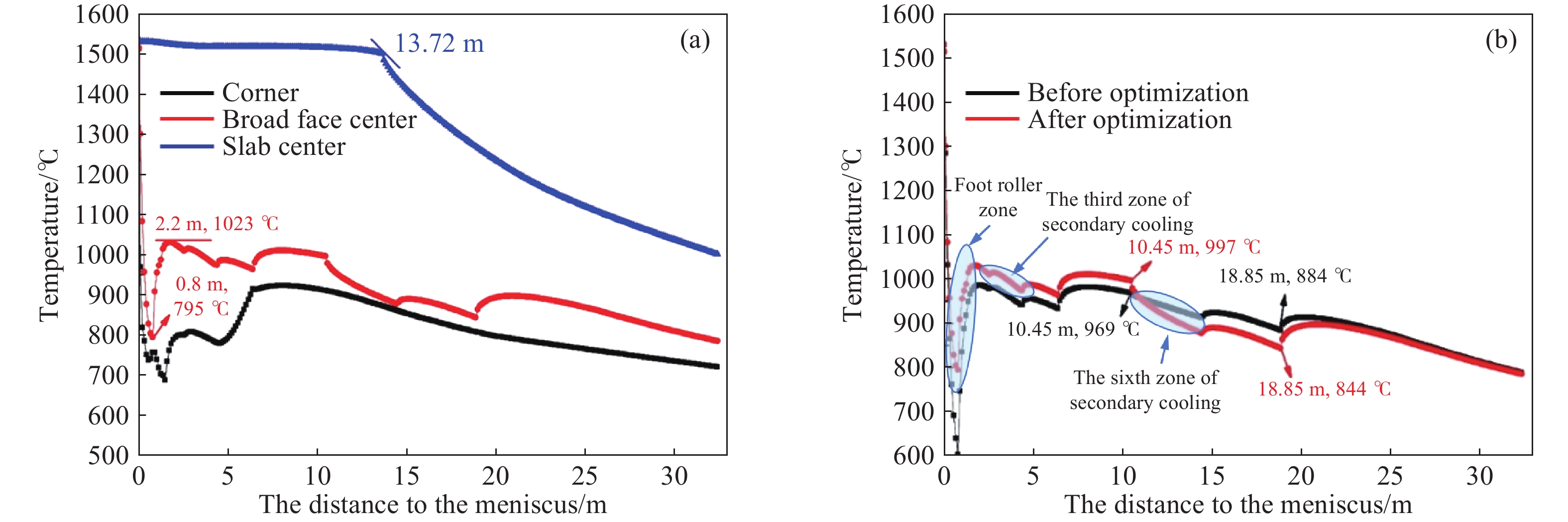

圖 5 凝固冷卻配水優化結果. (a) 配水優化后鑄坯特征溫度曲線; (b) 優化前/后連鑄坯寬面中心溫度變化對比[21]

Figure 5. Optimization results of solidification cooling water distribution: (a) characteristic temperature curves of the slab after optimization; (b) comparison of the temperature change at the center of the broad face before and after optimization

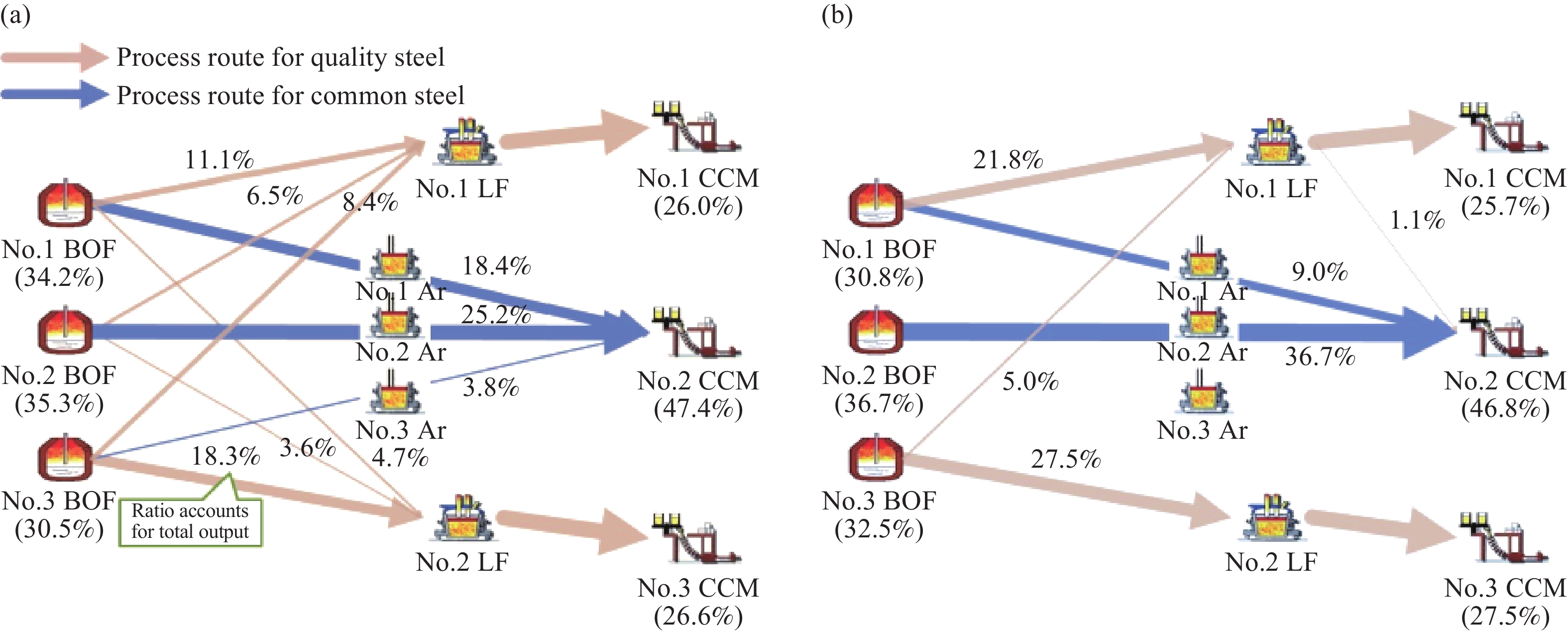

圖 7 模型應用前后爐?機對應關系. (a)應用前; (b)應用后[27]

Figure 7. Furnace-caster coordinating scenario: (a) before application; (b) after application

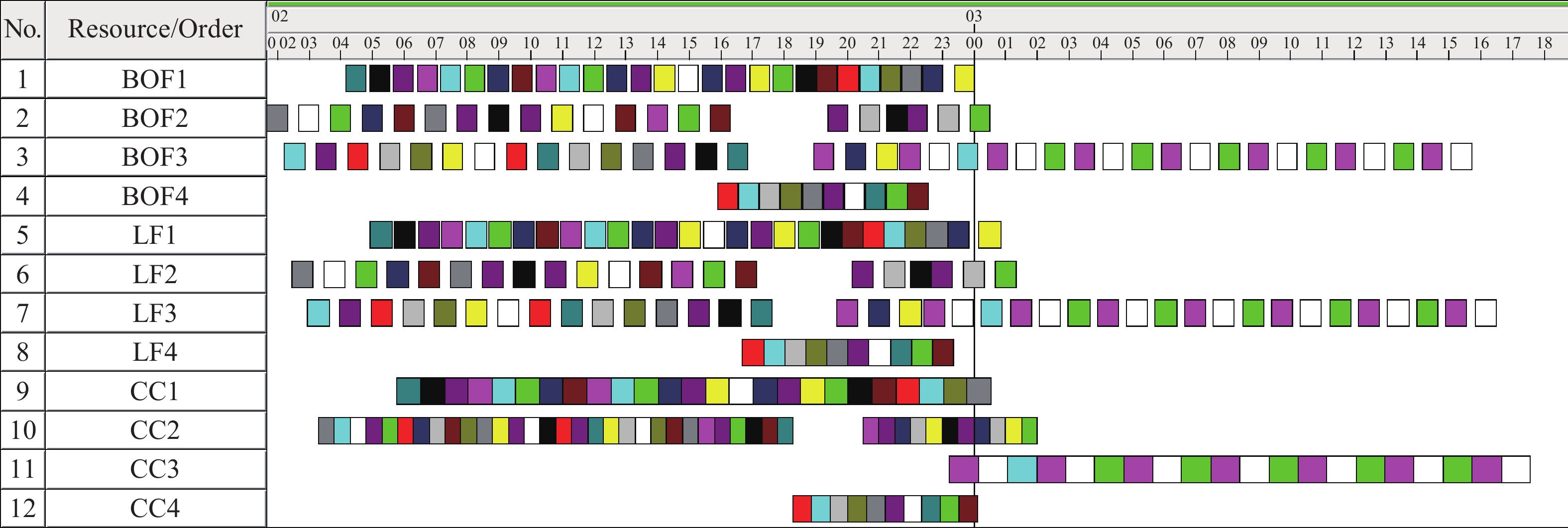

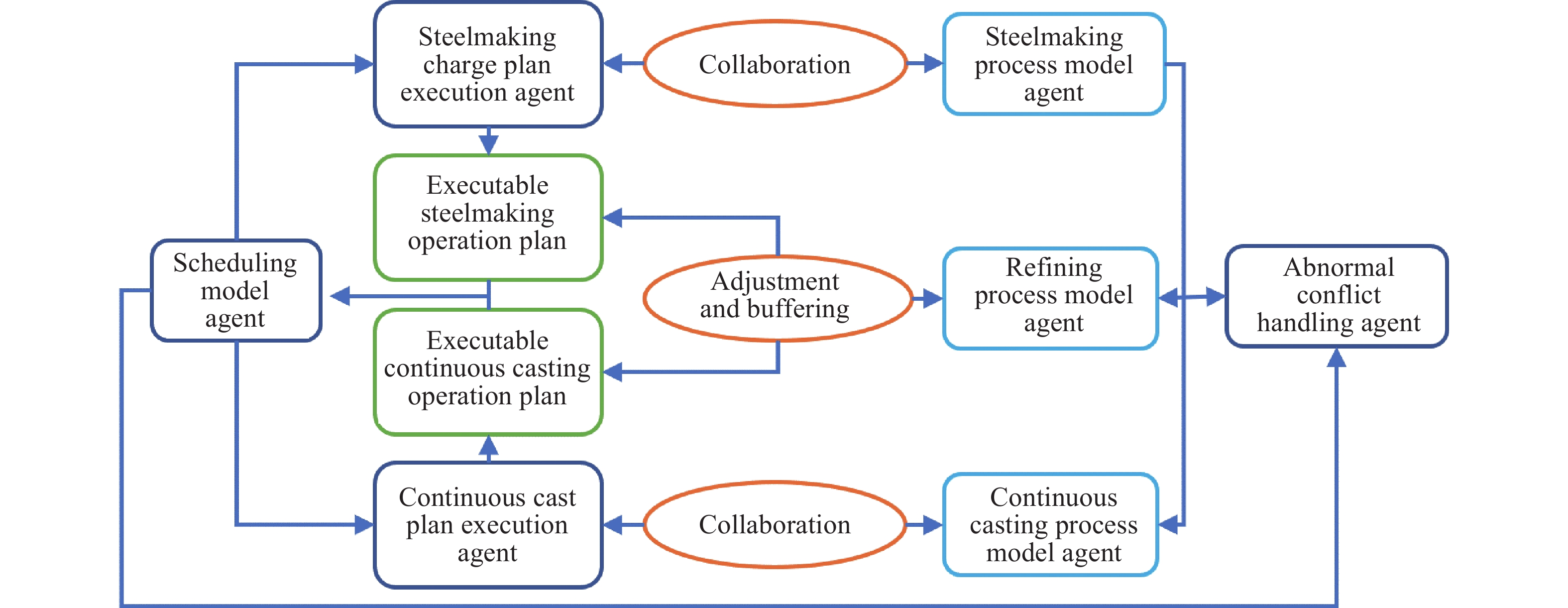

圖 10 基于多智能體技術的煉鋼?連鑄過程協同調度系統架構[46]

Figure 10. System architecture of collaborative scheduling for steelmaking plant based on multi-agent technology

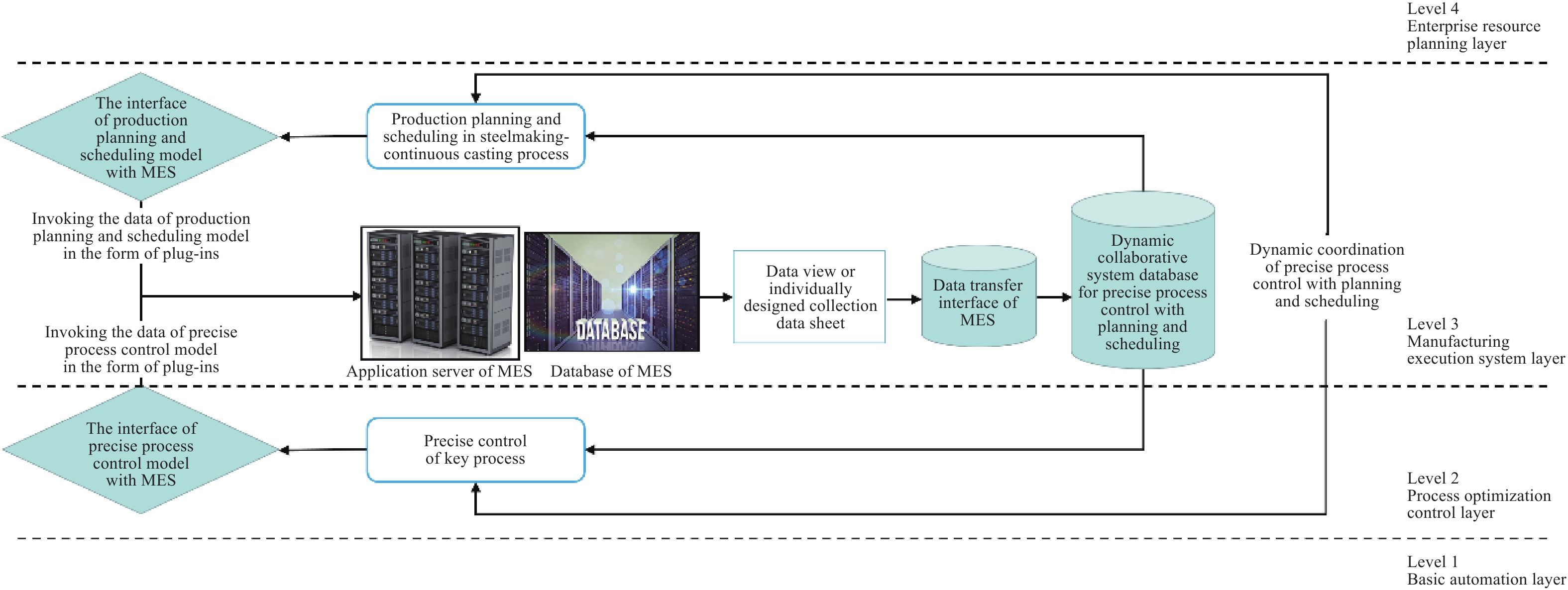

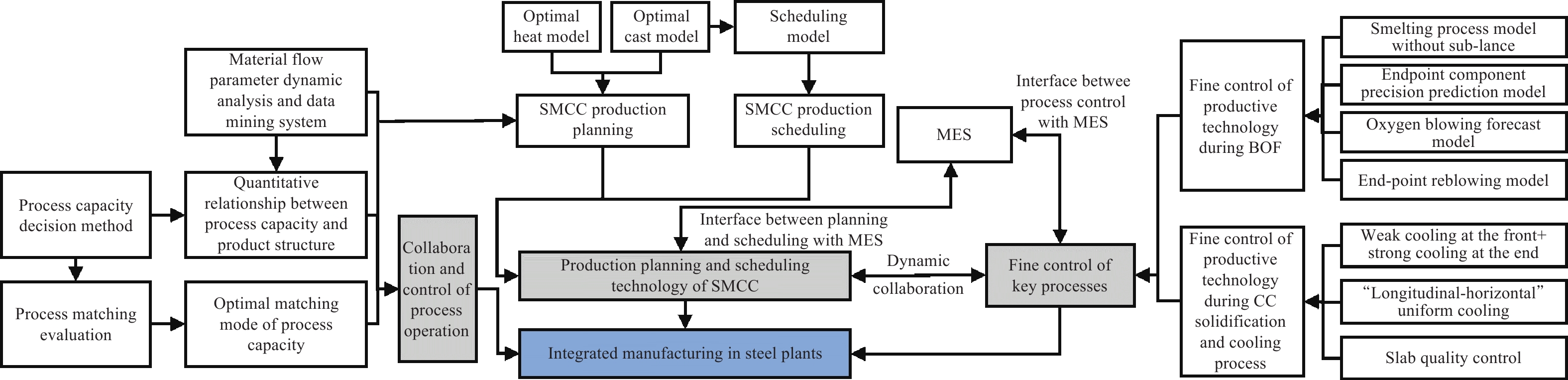

圖 12 煉鋼廠的集成制造技術路線圖[47]

Figure 12. Integrated manufacturing technology roadmap for steelmaking plants

表 1 RELM中心碳偏析預測模型的基本參數[22]

Table 1. Basic parameters of the central carbon segregation prediction model based on RELM[22]

Parameters Setting value Parameters Setting value Number of input layer neurons 7 Number of output layer neurons 1 Number of hidden layer neurons 50 Activation function sigmoid Regularization coefficient($ \lambda $) 0.1 表 2 三種智能算法求解算例的結果對比[33]

Table 2. Results of calculation examples solved by three algorithms

Calculation examples Heats Production mode Objective function /min Maximum waiting time between processes /min Proportion of waiting time more than 30 min between processes /% Maximum deviation of the cast starting time /min A1 A2 A3 A1 A2 A3 A1 A2 A3 A1 A2 A3 1 90 4BOF?3CCM 1952 2036 5735 65 34 103 6 16 57 0 0 105 2 93 3BOF?3CCM 4302 3944 4932 94 76 100 30 29 39 0 0 59 3 65 4BOF?3CCM 1371 1272 2926 45 43 97 9 7 40 0 0 94 4 77 4BOF?3CCM 2456 2014 4658 78 60 92 27 12 54 0 0 78 5 84 4BOF?3CCM 2932 2811 5518 106 88 110 22 18 60 0 0 110 6 77 4BOF?4CCM 2878 3055 6052 84 78 114 28 30 67 0 0 108 7 80 4BOF?4CCM 2968 2280 2532 116 84 88 27 15 23 0 0 52 8 67 4BOF?3CCM 2286 2091 4046 75 72 102 25 18 52 0 0 44 表 3 A、B兩廠2019年4月~7月期間系統層流運行指數RM與工序匹配度R[35]

Table 3. System laminar flow operation index RM and process matching index R for steelmaking plants A and B from April to July, 2019

Plant RM R April May June July April May June July A 0.647 0.638 0.639 0.629 0.608 0.601 0.631 0.599 B 1.000 1.000 1.000 1.000 0.749 0.789 0.720 0.776 中文字幕在线观看表 4 A廠4種調度模型的可用性評價指數

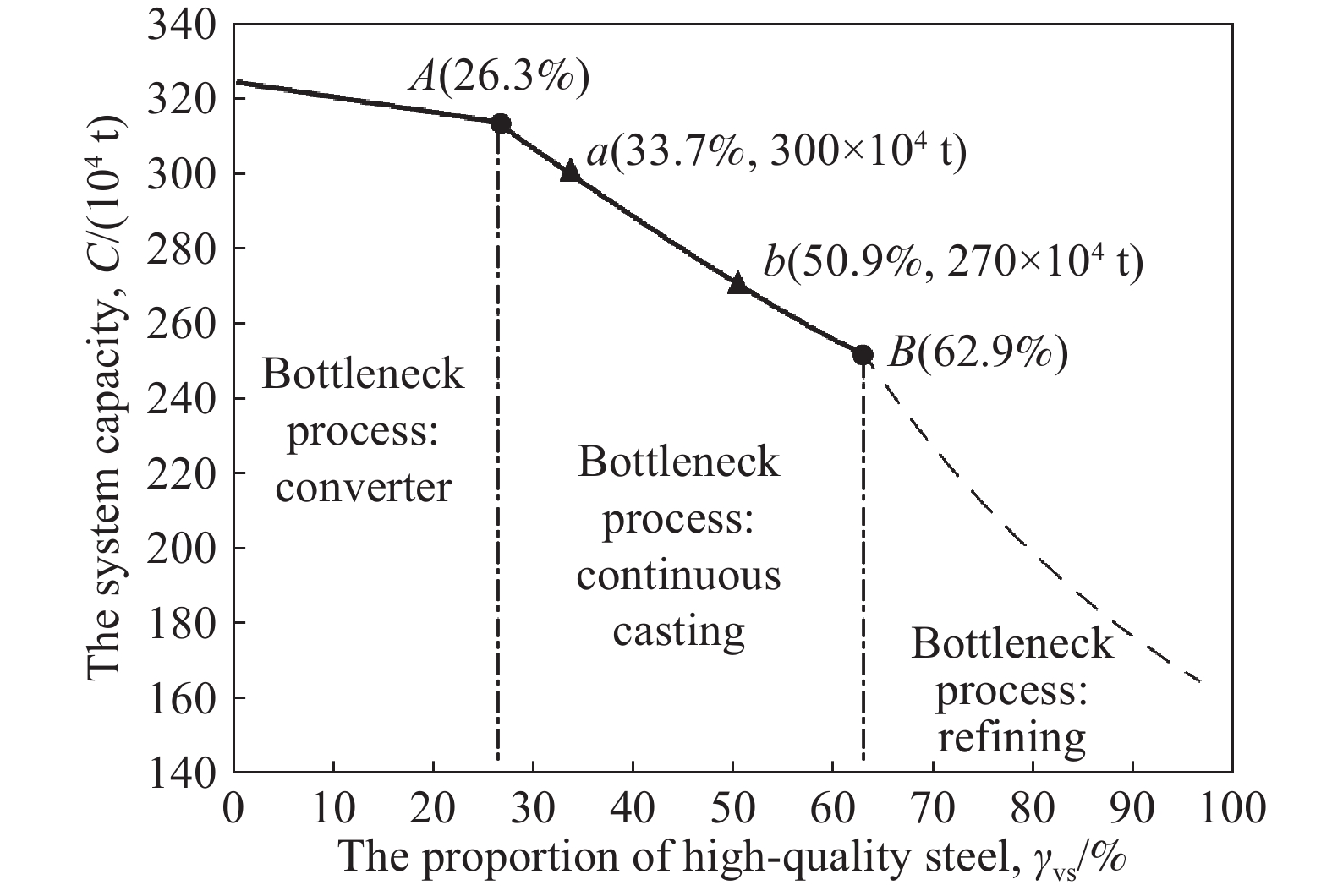

$ {\mathit{\varepsilon }}_{\mathit{p}} $ Table 4. Scheduling model availability degree

$ {\varepsilon }_{p} $ of the four scheduling models of Plant AScheduling model $ {\varepsilon }_{1,p} $ $ {\varepsilon }_{2,p} $ $ {\varepsilon }_{3,p} $ $ {\varepsilon }_{4,p} $ $ {\varepsilon }_{p} $ Model p1 0.965 0.85 0.918 0.897 0.919 Model p2 0.603 0.456 0.595 0.557 0.579 Model p3 0.124 0.146 0.069 0.344 0.115 Model p4 0.285 0.571 0.588 0.422 0.509 -

參考文獻

[1] Liu Q, Tian N Y, Yin R Y. Operation principle and control strategy for steelmaking workshop system. Chin J Process Eng, 2003, 3(2): 171 doi: 10.3321/j.issn:1009-606X.2003.02.015劉青, 田乃媛, 殷瑞鈺. 煉鋼廠系統的運行原則與調控策略. 過程工程學報, 2003, 3(2):171 doi: 10.3321/j.issn:1009-606X.2003.02.015 [2] Wang Z, Chang J, Ju Q P, et al. Prediction model of end-point manganese content for BOF steelmaking process. ISIJ Int, 2012, 52(9): 1585 doi: 10.2355/isijinternational.52.1585 [3] Lin W H, Jiao S Q, Sun J K, et al. Modified exponential model for carbon prediction in the end blowing stage of basic oxygen furnace converter. Chin J Eng, 2020, 42(7): 854林文輝, 焦樹強, 孫建坤, 等. 轉爐吹煉后期碳含量預報的改進指數模型. 工程科學學報, 2020, 42(7):854 [4] Wang Z, Xie F M, Wang B, et al. The control and prediction of end-point phosphorus content during BOF steelmaking process. Steel Res Int, 2014, 85(4): 599 doi: 10.1002/srin.201300194 [5] Li N, Lin W H, Cao L L, et al. Carbon prediction model for basic oxygen furnace off-gas analysis based on bath mixing degree. Chin J Eng, 2018, 40(10): 1244李南, 林文輝, 曹玲玲, 等. 基于熔池混勻度的轉爐煙氣分析定碳模型. 工程科學學報, 2018, 40(10):1244 [6] Zhang Z, Cao L L, Lin W H, et al. Improved prediction model for BOF end-point manganese content based on IPSO?RELM method. Chin J Eng, 2019, 41(8): 1052張壯, 曹玲玲, 林文輝, 等. 基于IPSO?RELM轉爐冶煉終點錳含量預測模型. 工程科學學報, 2019, 41(8):1052 [7] Fu G Q, Liu Q, Wang Z, et al. Grey box model for predicting the LF end-point temperature of molten steel. J Univ Sci Technol Beijing, 2013, 35(7): 948付國慶, 劉青, 汪宙, 等. LF精煉終點鋼水溫度灰箱預報模型. 北京科技大學學報, 2013, 35(7):948 [8] Xin Z C, Zhang J S, Zhang J G, et al. Mathematical modelling and plant trial on slagging regime in a ladle furnace for high-efficiency desulphurization. Ironmaking Steelmaking, 2021: 1 [9] Yang J P, Zhang J S, Guo W D, et al. End-point temperature preset of molten steel in the final refining unit based on an integration of deep neural network and multi-process operation simulation. ISIJ Int, 2021, 61(7): 2100 doi: 10.2355/isijinternational.ISIJINT-2020-540 [10] Dou K, Yang Z G, Liu Q, et al. Influence of secondary cooling mode on solidification structure and macro-segregation behavior for high-carbon continuous casting bloom. High Temp Mater Process, 2017, 36(7): 741 doi: 10.1515/htmp-2016-0022 [11] Yang Z G. Research on the Influencing Factors and Control of Carbon Macrosegregation of Blooms in Continuous Casting of GCr15 Bearing Steel [Dissertation]. Beijing: University of Science and Technology Beijing, 2014楊振國. GCr15軸承鋼連鑄坯宏觀碳偏析的影響因素及控制研究[學位論文]. 北京: 北京科技大學, 2014 [12] Chen H Z. Research on Prediction of Typical Defects of Continuous Casting Bloom [Dissertation]. Beijing: University of Science and Technology Beijing, 2017陳恒志. 連鑄坯典型缺陷預測研究[學位論文]. 北京: 北京科技大學, 2017 [13] Han Y S, Yan W, Zhang J S, et al. Optimization of thermal soft reduction on continuous-casting billet. ISIJ Int, 2020, 60(1): 106 doi: 10.2355/isijinternational.ISIJINT-2019-409 [14] Li G H, Wang B, Liu Q, et al. A process model for BOF process based on bath mixing degree. Int J Miner Metall Mater, 2010, 17(6): 715 doi: 10.1007/s12613-010-0379-4 [15] Wang Z. Study on the Control of Steelmaking Process and Blowing End-Point for Medium-High Carbon Steel Melting by Converter [Dissertation]. Beijing: University of Science and Technology Beijing, 2016汪宙. 轉爐冶煉中高碳鋼過程及終點控制研究[學位論文]. 北京: 北京科技大學, 2016 [16] Han Y S, Wang X Y, Zhang J S, et al. Comparison of transverse uniform and non-uniform secondary cooling strategies on heat transfer and solidification structure of continuous-casting billet. Metals, 2019, 9(5): 543 doi: 10.3390/met9050543 [17] Dou Z C, Zhang X F, Yin J, et al. Secondary cooling control model based on effective-speed and effective-superheat in continuous casting. J Univ Sci Technol Beijing, 2011, 33(11): 1349竇志超, 張曉峰, 尹佳, 等. 基于有效拉速和有效過熱度的連鑄二冷控制模型. 北京科技大學學報, 2011, 33(11):1349 [18] Dou K, Liu Q. A new cooling strategy in curved continuous casting process of vanadium micro-alloyed YQ450NQR1 steel bloom combining experimental and modeling approach. Metall Mater Trans A, 2020, 51(8): 3945 doi: 10.1007/s11661-020-05819-9 [19] Liu Q, Han Y S, Zhang J S. Method for Improving Center Segregation and Surface Cracks of Peritectic Steel Continuous Casting Medium-Thickness Slab: China Patent, CN111774546B. 2021-03-30劉青, 韓延申, 張江山. 一種改善包晶鋼連鑄中厚板坯中心偏析與表面裂紋的方法: 中國專利, CN111774546B. 2021-03-30 [20] Dou K. Research on Solidification Characteristics and Microstructure Properties for Vanadium Micro-Alloyed Steel Bloom in Continuous Casting Process [Dissertation]. Beijing: University of Science and Technology Beijing, 2017竇坤. 釩微合金化鋼連鑄方坯凝固特性與組織性能研究[學位論文]. 北京: 北京科技大學, 2017 [21] Chen S. Research on Secondary Cooling Optimization and Typical Defects of Continuous Casting Slabs [Dissertation]. Beijing: University of Science and Technology Beijing, 2018陳尚. 連鑄板坯二冷優化與典型缺陷研究[學位論文]. 北京: 北京科技大學, 2018 [22] Zou L L, Zhang J S, Liu Q, et al. Prediction of central carbon segregation in continuous casting billet using A regularized extreme learning machine model. Metals, 2019, 9(12): 1312 doi: 10.3390/met9121312 [23] Yin R Y. A discussion on “smart” steel plant—view from physical system side. Iron Steel, 2017, 52(6): 1殷瑞鈺. 關于智能化鋼廠的討論——從物理系統一側出發討論鋼廠智能化. 鋼鐵, 2017, 52(6):1 [24] Liu Q, Wang G, Wang B, et al. Capacity analysis of steelmaking-continuous casting section based on different products mixes. J Chongqing Univ, 2014, 37(1): 75 doi: 10.11835/j.issn.1000-582X.2014.01.012劉青, 王剛, 王彬, 等. 基于產品結構的煉鋼?連鑄區段產能解析. 重慶大學學報, 2014, 37(1):75 doi: 10.11835/j.issn.1000-582X.2014.01.012 [25] Mu Y Q. Research on Operation Optimization for Productive Process of Steelmaking-Continuous Casting in BOF Special Steel Plants [Dissertation]. Beijing: University of Science and Technology Beijing, 2011穆衍清. 轉爐特殊鋼廠煉鋼−連鑄生產過程運行優化研究[學位論文]. 北京: 北京科技大學, 2011 [26] Liu Q, Huang X W, Fu P Y. Production mode optimization of a steelmaking workshop system. J Univ Sci Technol Beijing, 2005, 27(6): 736 doi: 10.3321/j.issn:1001-053X.2005.06.024劉青, 黃星武, 富平原. 煉鋼廠系統生產模式優化. 北京科技大學學報, 2005, 27(6):736 doi: 10.3321/j.issn:1001-053X.2005.06.024 [27] Yang J P, Zhang J S, Liu Q. Research progress on three kinds of classic process interface technologies in steelmaking-continuous casting section. Chin J Eng, 2020, 42(12): 1542楊建平, 張江山, 劉青. 煉鋼?連鑄區段3種典型工序界面技術研究進展. 工程科學學報, 2020, 42(12):1542 [28] Wang B, Wang C, Wang B, et al. Comprehensive optimization of production planning and scheduling for steelmaking-continuous casting process. J Wuhan Univ Sci Technol, 2014, 37(3): 161王彬, 王闖, 王寶, 等. 煉鋼-連鑄過程生產計劃與調度問題綜合優化研究. 武漢科技大學學報, 2014, 37(3):161 [29] Wang C, Liu Q, Li Q Y, et al. Optimal charge plan model for steelmaking based on modified partheno-genetic algorithm. Control Theory Appl, 2013, 30(6): 734王闖, 劉青, 李慶益, 等. 基于改進單親遺傳算法的煉鋼最優爐次計劃模型. 控制理論與應用, 2013, 30(6):734 [30] Zou C Y. Research on Planning Optimization for Steelmaking-Continuous Casting Process in Special Steel Plants of Long Products [Dissertation]. Beijing: University of Science and Technology Beijing, 2016鄒草云. 長材型特殊鋼廠煉鋼−連鑄過程生產計劃優化研究[學位論文]. 北京: 北京科技大學, 2016 [31] Liu Q. Rule-Based Genetic Algorithm Model of Production Scheduling for Steelmaking-Continuous Casting Process [Dissertation]. Beijing: University of Science and Technology Beijing, 2020劉倩. 基于規則的煉鋼-連鑄過程生產調度遺傳算法模型[學位論文]. 北京: 北京科技大學, 2020 [32] Liu Q, Liu Q, Yang J P, et al. Progress of research on steelmaking-continuous casting production scheduling. Chin J Eng, 2020, 42(2): 144劉青, 劉倩, 楊建平, 等. 煉鋼?連鑄生產調度的研究進展. 工程科學學報, 2020, 42(2):144 [33] Liu Q, Yang J P, Wang B L, et al. Genetic optimization model of steelmaking-continuous casting production scheduling based on the “furnace-caster coordinating” strategy. Chin J Eng, 2020, 42(5): 645劉倩, 楊建平, 王柏琳, 等. 基于“爐?機對應”的煉鋼?連鑄生產調度問題遺傳優化模型. 工程科學學報, 2020, 42(5):645 [34] Shao X, Yang J P, Wang B L, et al. Cooperative control of multi-process operation in steelmaking-continuous casting section. Iron Steel, 2021, 56(8): 101邵鑫, 楊建平, 王柏琳, 等. 煉鋼?連鑄區段多工序運行協同控制. 鋼鐵, 2021, 56(8):101 [35] Yang J P, Liu Q, Guo W D, et al. Quantitative evaluation of multi-process collaborative operation in steelmaking-continuous casting sections. Int J Miner Metall Mater, 2021, 28(8): 1353 doi: 10.1007/s12613-020-2227-5 [36] Mu Y Q, Yin J, Xie F M, et al. Research on matching between furnaces and casters in special steel plants. J Univ Sci Technol Beijing, 2013, 35(1): 126穆衍清, 尹佳, 謝飛鳴, 等. 特殊鋼廠爐機匹配研究. 北京科技大學學報, 2013, 35(1):126 [37] Yang J P, Wang B L, Liu Q, et al. Scheduling model for the practical steelmaking-continuous casting production and heuristic algorithm based on the optimization of “furnace-caster matching” mode. ISIJ Int, 2020, 60(6): 1213 doi: 10.2355/isijinternational.ISIJINT-2019-423 [38] Xu Z J, Zheng Z, Gao X Q. HGA combined with priority strategy for production planning of steelmaking-continuous casting. Control Decis, 2016, 31(8): 1394徐兆俊, 鄭忠, 高小強. 煉鋼連鑄生產調度的優先級策略混合遺傳算法. 控制與決策, 2016, 31(8):1394 [39] Liu G H, Li T K. A steelmaking-continuous casting production scheduling model and its heuristic algorithm. Syst Eng, 2002, 20(6): 44 doi: 10.3969/j.issn.1001-4098.2002.06.009劉光航, 李鐵克. 煉鋼?連鑄生產調度模型及啟發式算法. 系統工程, 2002, 20(6):44 doi: 10.3969/j.issn.1001-4098.2002.06.009 [40] Yin J. The Rational Arrangement of Ladle Furnace of the Medium and Small Sized Converters Process and its Influence to Production [Dissertation]. Beijing: University of Science and Technology Beijing, 2007尹佳. 中小轉爐流程LF的合理配置及其對生產運行的影響研究[學位論文]. 北京: 北京科技大學, 2007 [41] Liu Q, Zhao P, Wu X D, et al. Control strategy for ladle running. J Univ Sci Technol Beijing, 2005, 27(2): 235 doi: 10.3321/j.issn:1001-053X.2005.02.025劉青, 趙平, 吳曉東, 等. 鋼包的運行控制. 北京科技大學學報, 2005, 27(2):235 doi: 10.3321/j.issn:1001-053X.2005.02.025 [42] Hong Y J, Yang J P, Liu Q, et al. Establishment of calculation model for number of offline baked steel ladle. J Iron Steel Res, 2021, 33(3): 209洪宇杰, 楊建平, 劉青, 等. 離線烘烤鋼包數量計算模型建立. 鋼鐵研究學報, 2021, 33(3):209 [43] Yu X Z. Research on Optimization and Simulation of Ladle Operation in Steelmaking Plant [Dissertation]. Beijing: University of Science and Technology Beijing, 2019余相灼. 煉鋼廠鋼包運行優化與仿真模擬研究[學位論文]. 北京: 北京科技大學, 2019 [44] Torre?o A, Sapena ó, Onaindia E. FMAP: A platform for the development of distributed multi-agent planning systems. Knowl Based Syst, 2018, 145: 166 doi: 10.1016/j.knosys.2018.01.013 [45] Ren W, Beard R W. Consensus seeking in multiagent systems under dynamically changing interaction topologies. IEEE Trans Autom Control, 2005, 50(5): 655 doi: 10.1109/TAC.2005.846556 [46] Wang B. Optimal Planning and Collaborative Scheduling on Steelmaking-Continuous Casting Process in Special Steel Plantsof Long Products [Dissertation]. Beijing: University of Science and Technology Beijing, 2015王彬. 長材型特殊鋼廠煉鋼−連鑄過程生產計劃優化與協同調度[學位論文]. 北京: 北京科技大學, 2015 [47] Liu Q, Wang B, Wang Z, et al. Fine manufacturing for steelmaking-continuous casting process of high quality steel. Continuous Cast, 2016, 41(3): 1劉青, 王彬, 汪宙, 等. 高品質鋼煉鋼?連鑄過程的精益制造. 連鑄, 2016, 41(3):1 [48] Liu Q, Wang B, Wang Z, et al. Fine production in steelmaking plants. Mater Today Proc, 2015, 2: S348 doi: 10.1016/j.matpr.2015.05.049 -

下載:

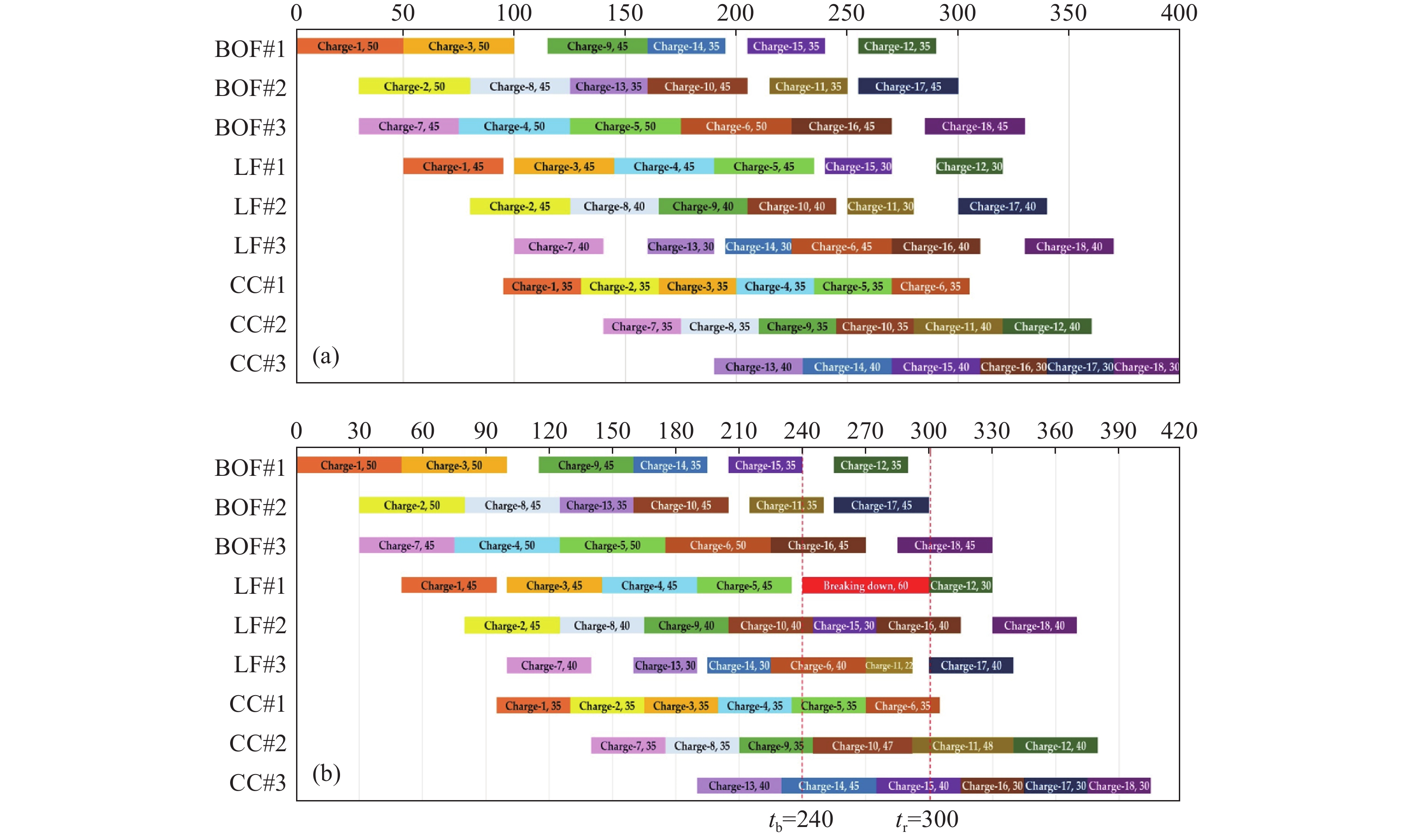

下載: